Mechanical welding and grinding integrated device

A mechanical welding, integrated technology, applied in the field of mechanical processing, to achieve good results, increase the scope of application, improve the applicability of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

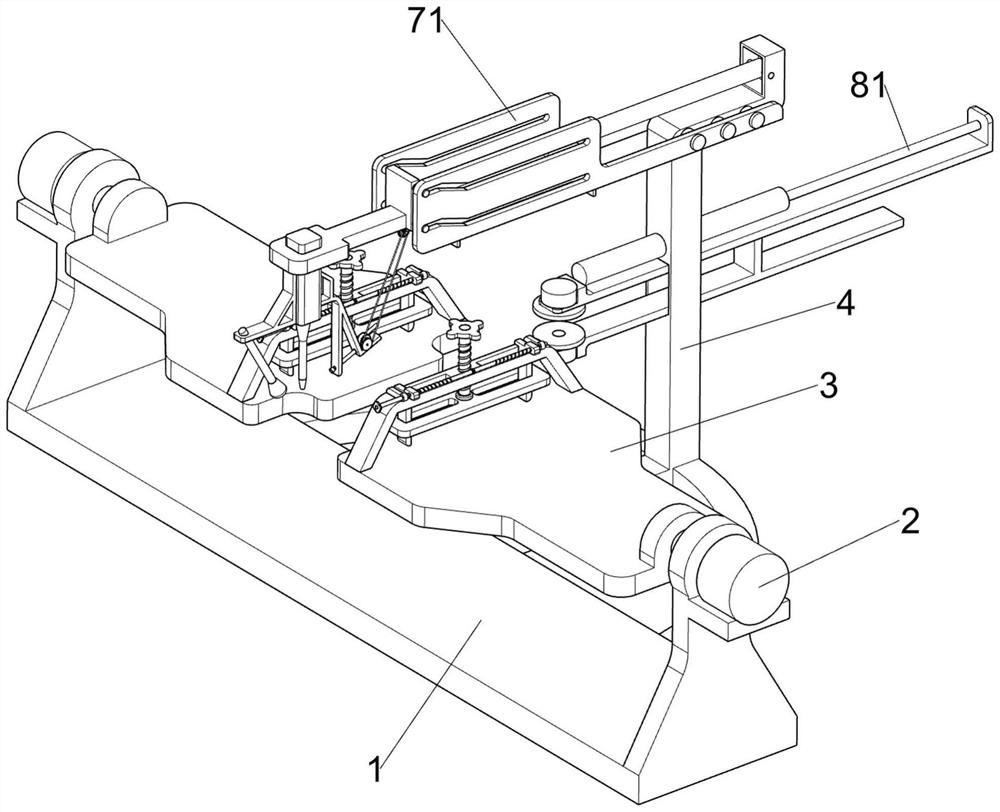

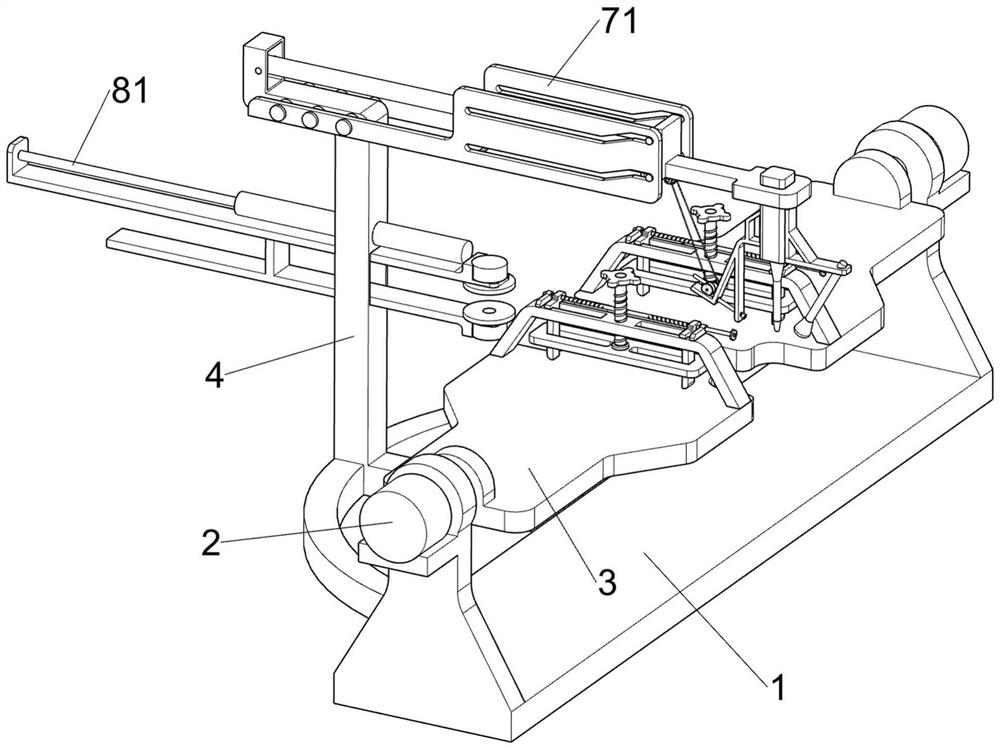

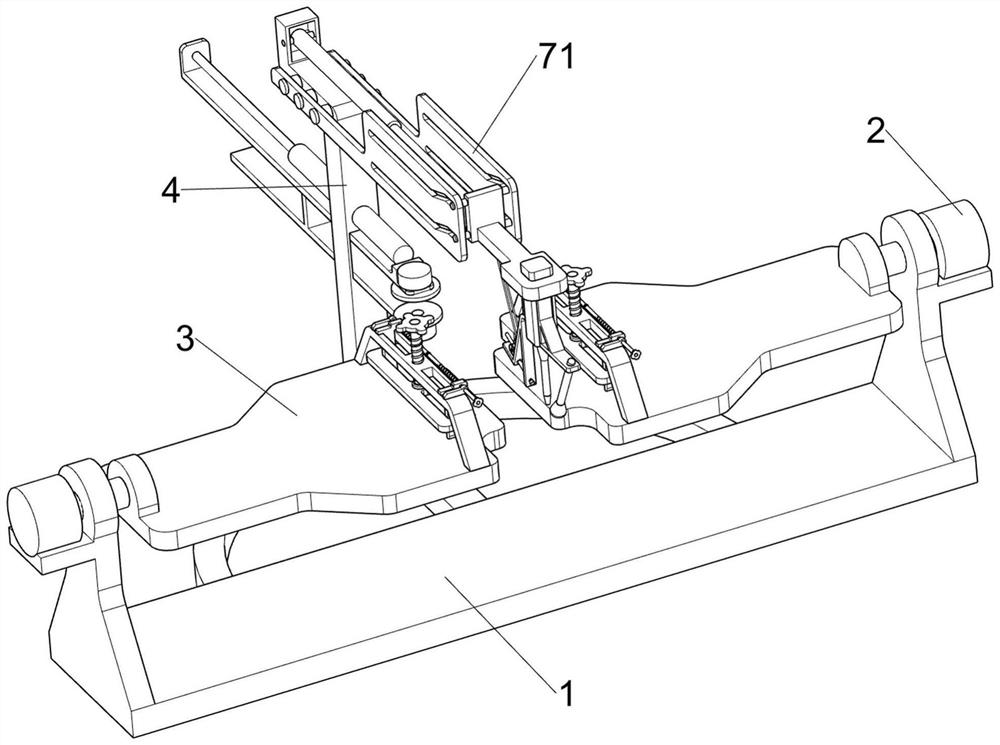

[0041] A mechanical welding and grinding integrated device, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, it includes a bottom plate 1, a steering motor 2, a placement plate 3, a fixed main frame 4, an extrusion fixing component 5, a width limit adjustment component 6, a laser welding component 7, a grinding component 8 and a gas protection component 10. The upper part of the bottom plate 1 A steering motor 2 is symmetrically fixed, and the output shaft of the steering motor 2 is rotationally connected with the base plate 1. One end of the output shaft of the steering motor 2 is fixedly connected with a placement plate 3, and the steering motor 2 is used to drive the placement plate 3 to turn over. The side is fixedly connected with a fixed main frame 4, and the placing plate 3 is provided with an extruding and fixing assembly 5, which is used to extrude and limit the top of the workpiece, and the extruding and fixing assembly 5 is p...

Embodiment 2

[0052] On the basis of Example 1, such as Figure 7-11 As shown, an inert gas recovery assembly 9 is also included, and the inert gas recovery assembly 9 is arranged on the laser welding assembly 7. The inert gas recovery assembly 9 includes a fixed rack 91, a rotating gear 92, a large pulley 93, and a small pulley 94 , belt 95, air suction cylinder 96, the third rotating shaft 97, transmission gear 98 and fan blade 99, the fixed guide plate 71 bottom that is positioned at the right side is affixed with fixed rack 91, and the sliding seat 72 bottom rotatably is connected with rotating gear 92 The bottom of the special-shaped frame 76 is rotatably connected with a large pulley 93, the rotating gear 92 is fixedly connected with a small pulley 94, a belt 95 is wound between the large pulley 93 and the small pulley 94, and the bottom of the special-shaped frame 76 is fixedly connected with a suction ring. Air cylinder 96, on the air suction cylinder 96, the third rotating shaft 97...

Embodiment 3

[0055] On the basis of Example 2, such as Figure 5 As shown, it also includes a connecting rod 11, the bottom of the pole 82 is connected to the connecting rod 11 by welding, the connecting rod 11 passes through the fixed main frame 4, and the front part of the connecting rod 11 is also fixedly connected with a grinder 83.

[0056] During the forward movement of the pole 82 and its upper device, the connecting rod 11 will also move together, so that the two grinding machines 83 can simultaneously grind the welds on both sides of the mechanical workpiece, so that there is no need to put the The mechanical workpiece is turned over, saving unnecessary trouble.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com