Thermal expansion microsphere with particle size of 1-100 microns prepared by emulsion polymerization

A heat-expandable microsphere and emulsion polymerization technology, which is applied in the field of polymer materials, can solve the problems of long production cycle, complex process, and high production equipment requirements, and achieve the effects of low initiation temperature, simple processing technology, and high utilization rate of blowing agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

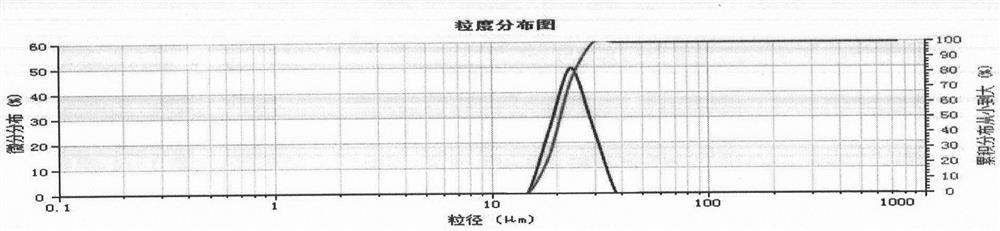

Image

Examples

Embodiment 1

[0024] A heat-expandable microsphere prepared by emulsion polymerization, composed as follows by mass: 30 parts of acrylonitrile, 10 parts of methyl acrylate, 40 parts of isooctane, 2 parts of allyl-2-propyl sodium ethanesulfonate, peroxide 0.1 part of benzoyl, 30 parts of nano silicon dioxide, 140 parts of water.

[0025] The preparation method of the acrylic acid modified polyimide oligomer solution in the present embodiment is as follows:

[0026] (1) Under normal temperature and pressure, add monomer acrylonitrile and acrylic acid monomer: 3:1 into the reactor, then add 40 parts of isooctane, then add 0.1 part of benzoyl peroxide, and then stir at room temperature , mixed for 30min to obtain a homogeneous oil phase;

[0027] (2) Add 2 parts of allyl-2-propyl sodium ethanesulfonate, 30 parts of rice silica, and 140 parts of deionized water into the reaction vessel at normal temperature and pressure, and stir at normal temperature to obtain a uniform mixture. water box.

...

Embodiment 2

[0031] A heat-expandable microsphere prepared by emulsion polymerization, composed as follows by mass: 50 parts of acrylonitrile, 10 parts of methyl acrylate, 60 parts of isooctane, 2 parts of allyl-2-propyl sodium ethanesulfonate, peroxide 0.2 parts of benzoyl, 50 parts of nano silicon dioxide, and 200 parts of water.

[0032] The preparation method of the acrylic acid modified polyimide oligomer solution in the present embodiment is as follows:

[0033] (1) Under normal temperature and pressure, add monomer acrylonitrile and acrylic acid monomer: 5:1 into the reactor, then add 60 parts of isooctane, then add 0.2 part of benzoyl peroxide, and then stir at room temperature , mixed for 30min to obtain a homogeneous oil phase;

[0034] (2) Add 2 parts of allyl-2-propyl sodium ethanesulfonate, 50 parts of rice silica, and 200 parts of deionized water into the reaction vessel at normal temperature and pressure, and stir at normal temperature to obtain a uniformly mixed water box...

Embodiment 3

[0038] A heat-expandable microsphere prepared by emulsion polymerization, composed as follows by mass: 50 parts of acrylonitrile, 20 parts of methyl acrylate, 50 parts of isooctane, 2 parts of allyl-2-propyl sodium ethanesulfonate, peroxide 0.2 parts of benzoyl, 50 parts of nano silicon dioxide, and 200 parts of water.

[0039] The preparation method of the acrylic acid modified polyimide oligomer solution in the present embodiment is as follows:

[0040] (1) Under normal temperature and pressure, add monomer acrylonitrile and acrylic acid monomer: 5:2 into the reactor, then add 50 parts of isooctane, then add 0.2 part of benzoyl peroxide, and then stir at room temperature , mixed for 30min to obtain a homogeneous oil phase;

[0041] (2) Add 2 parts of allyl-2-propyl sodium ethanesulfonate, 50 parts of rice silica, and 200 parts of deionized water into the reaction vessel at normal temperature and pressure, and stir at normal temperature to obtain a uniformly mixed water box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com