Highly adaptable multi-branched amidoimide type polycarboxylate water reducer and preparation method thereof

A branched amidoimide type polycarboxylic acid and amidoimide type technology, which is applied in the field of concrete admixtures, can solve the problems of few research reports and time-consuming industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

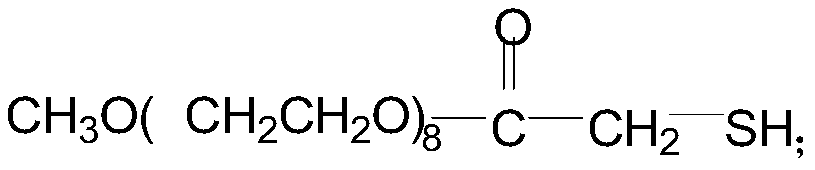

Method used

Image

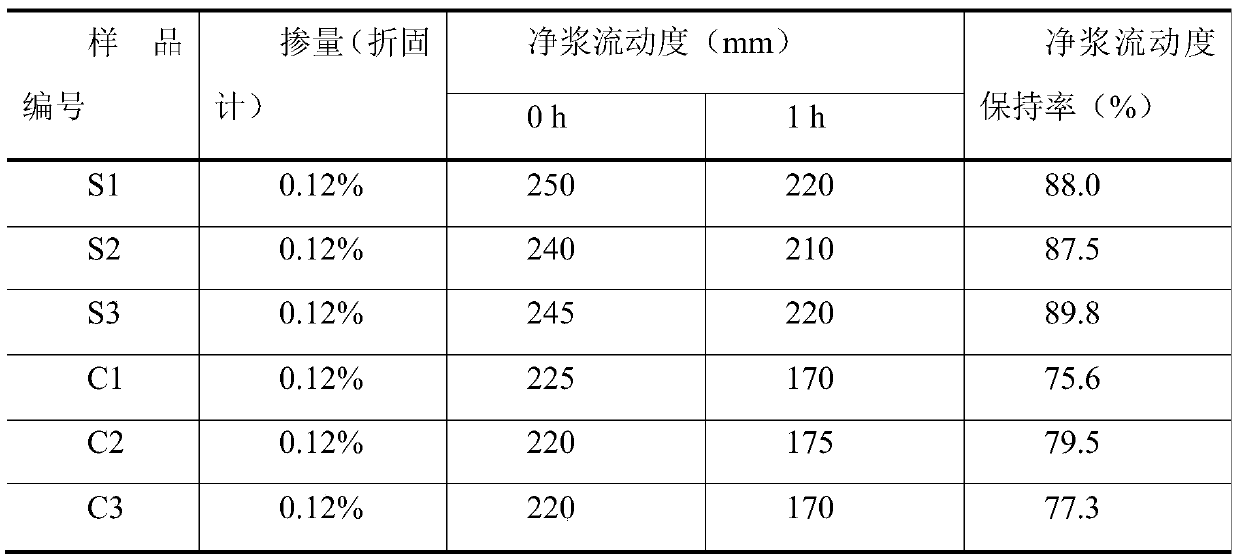

Examples

Embodiment 1

[0043] The molecular weight of HPEG is 3000, the molar ratio of the HPEG macromer: AA: XAY: JYQ is 1:3.0:0.3:0.6, and the initiator is H 2 o 2 , its dosage is 1.3wt% of the total mass of the monomer, H 2 o2 The mass ratio to VC is 1:0.3.

[0044] Add HPEG to the reaction bottle, and add quantitative deionized water to make a 50% aqueous solution, turn on the stirring, and raise the temperature to 60°C. AA, XAY, JYQ, VC and a certain amount of water make 40% aqueous solution A, initiator H 2 o 2 Make 2.0% aqueous solution B, and add it dropwise to the bottom liquid at 60°C at the same time. Among them, material A is dripped at a constant speed in 2.0 hours, and material B is dripped at a constant speed in 2.5 hours. After adding material B, continue to keep warm at 60°C for 2.0h. Lower the temperature to below 30°C, adjust the pH to 7.0 with sodium hydroxide, and then add water to adjust the solid content to 30%, which is the multi-branched amidoimide polycarboxylate supe...

Embodiment 2

[0046] The molecular weight of TPEG is 1200, the molar ratio of TPEG macromer: AA: XAY: JYQ is 1:5.0:0.5:0.8, the initiator is APS, and its dosage is 1.0wt% of the total mass of the monomer, and the mass ratio of APS and VC is 1 :0.5.

[0047] Add TPEG to the reaction bottle, and add quantitative deionized water to prepare an aqueous solution with a concentration of 60%, turn on the stirring, and raise the temperature to 50°C. Make AA, XAY, JYQ, VC and a certain amount of water to make 50% aqueous solution A, add water to initiator APS to make 3.0% aqueous solution B, and drop them into the bottom liquid at 50°C at the same time. Among them, material A was dripped at a constant speed in 1.5 hours, and material B was dripped at a constant speed in 2.0 hours. After adding material B, continue to keep warm at 50°C for 1.0h. Lower the temperature to below 30°C, adjust the pH to 7.0 with sodium hydroxide, and then add water to adjust the solid content to 40%, which is the multi-b...

Embodiment 3

[0049] TPEG molecular weight 2400, HPEG molecular weight 3000, the TPEG and HPEG macromonomer: the molar ratio of MAA: XAY: JYQ is 1:4.0:0.6:1.0, and the initiator is Na 2 o 2 , its dosage is 0.8wt% of the total mass of the monomer, N 2 o 2 The mass ratio to VC is 1:0.5.

[0050] Add TPEG and HPEG into the reaction bottle, and add quantitative deionized water to prepare an aqueous solution with a concentration of 65%, turn on the stirring, and raise the temperature to 40°C. Mix AA, XAY, JYQ, VC and a certain amount of water to form a 60% aqueous solution A, the initiator Na 2 o 2 Add water to make 5% aqueous solution B, and drop it into the bottom liquid at 40°C at the same time. Among them, material A is dripped at a constant speed in 2.5 hours, and material B is dripped at a constant speed in 3.0 hours. After adding material B, continue to keep warm at 40°C for 2.0h. Lower the temperature to below 30°C, adjust the pH to 8.0 with sodium hydroxide, and then add water to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com