Piezoelectric ceramic with laminated structure and preparation method and application thereof

A technology of piezoelectric ceramics and laminated structures, applied in the field of piezoelectric ceramics, can solve problems such as limited randomness of improvement, and achieve the effects of improved temperature stability, good performance, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

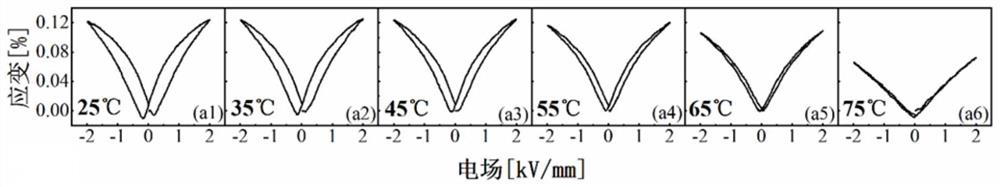

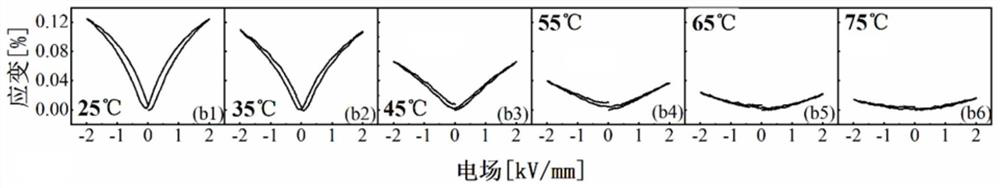

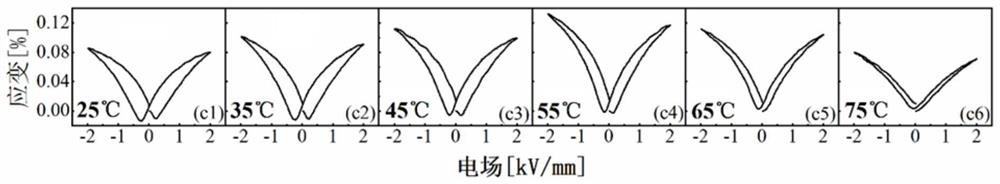

[0041] Considering the optimization of the room temperature and the device’s normal heating temperature range of 25-75°C near the electrostrain and temperature stability of piezoelectric ceramics, the barium titanate system doped with Sn4+ and Hf4+ is selected, and the multiphase coexistence point of the two corresponds to the temperature They are 37°C and 70°C, respectively, so the combination of several components near the multiphase coexistence point improves the electrostrain and temperature stability of piezoelectric ceramics.

[0042] (1) For doped Sn 4+ The barium titanate system, namely Ba(Ti 1-x sn x )O 3 (BTS x ), x refers to BaSnO 3 The percentage of the total amount of substances, studies have shown that the corresponding component of the multi-phase coexistence point of the system is BTS 0.105 . For doped Hf 4+ The barium titanate system, namely Ba(Ti 1-y f y )O 3 (BTH y ), y refers to BaHfO 3 The percentage of the total amount of substances, studies hav...

Embodiment 2

[0058] The difference between this embodiment and embodiment 1 is that the step (8) in the above embodiment 1 is different. Specifically, in this embodiment, after the piezoelectric ceramic powder is laid layer by layer, the Pressed under pressure for 3 minutes to prepare a semi-finished product, other steps are the same as in Example 1.

Embodiment 3

[0060] The difference between this embodiment and embodiment 1 is that the step (8) in the above embodiment 1 is different, specifically, in this embodiment, weigh 0.3g of BTS 0.12 Pour it into a 10mm mold and pre-press it with a pressure of 2MPa for 0.5min to make the surface of the sample flat. On this basis, add BTS one by one at a time of 0.3g 0.105 、BTS 0.09 、BTH 0.13 、BTH 0.11 and BTH 0.09 The sample powder is pre-pressed in the same pre-pressing way. After all the ingredients are pre-pressed, keep it for 7 minutes for the last time. Put the pre-pressed sample into a latex bag and vacuumize it, then put it into a cold isostatic press and press it into a dense laminated structure ceramic sample with a pressure of 200 MPa, and the pressing time is 5 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com