Spraying device for aluminum strip continuous production line

A technology of spraying device and production line, applied in spraying device, device for coating liquid on the surface, coating and other directions, can solve the problems of uneven temperature coating drying, unreasonable method, affecting product quality, etc., to improve drying effect, extend the travel stroke, improve the effect of spray adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

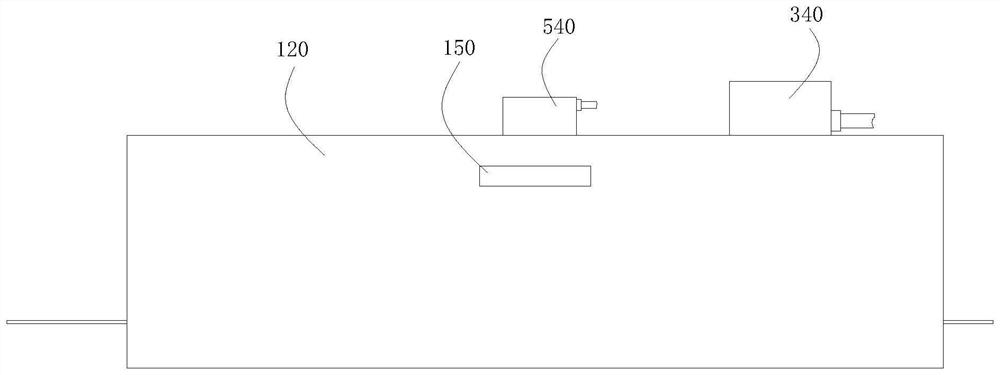

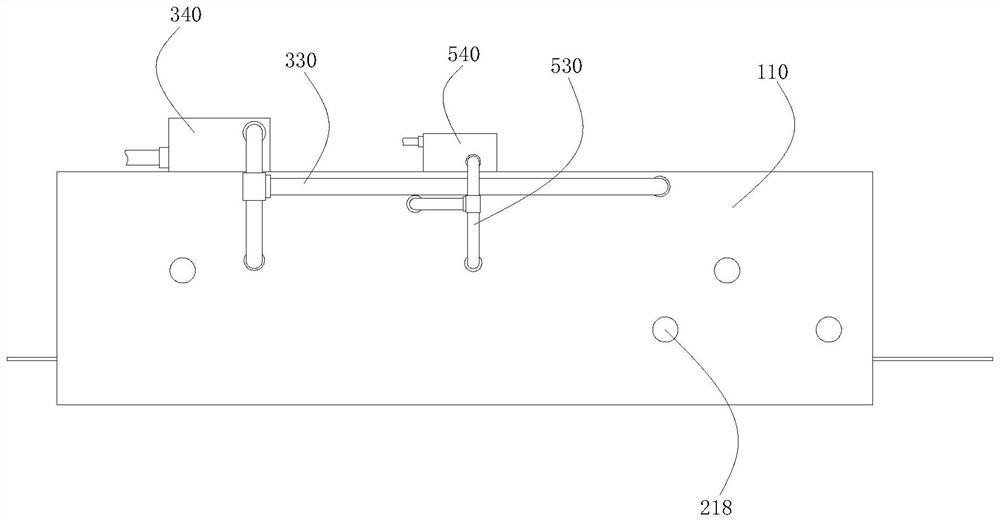

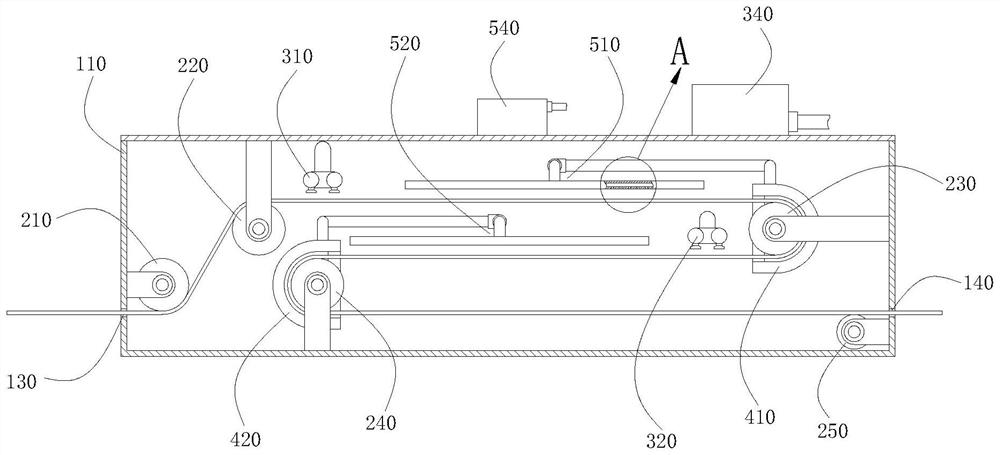

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0023] Such as Figure 1 to Figure 6 As shown, a spraying device for a continuous production line of aluminum strips is disclosed in a specific embodiment of the present invention, comprising a box body 110 with one side open, a box door 120 is installed on the open side of the box body 110, two sides of the box body 110 The end face is correspondingly provided with a material inlet 130 and a material outlet 140; the inner turret of the box body 110 is provided with a first support roller 210, a second support roller 220, a third support roller 230, and a fourth support roller 240 extending along the width direction , the fifth support roller 250, the first support roller 210 is located above the feed inlet 130 side, the second support roller 220 and the third support roller 230 are at the same heig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com