Sterile egg production process for salmonella

A Salmonella and production process technology, applied in the directions of bifidobacteria, bacteria used in food preparation, food science, etc., can solve the problem of not being able to prevent the infection of eggs and their products well, and achieve the goal of being conducive to commercial application and practical The effect of strong sex and saving breeding cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

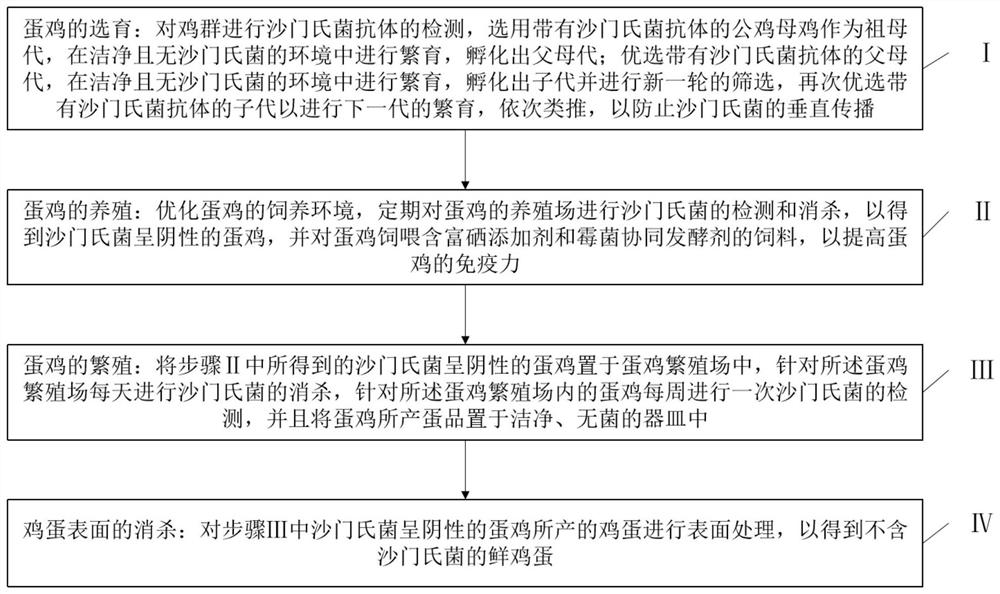

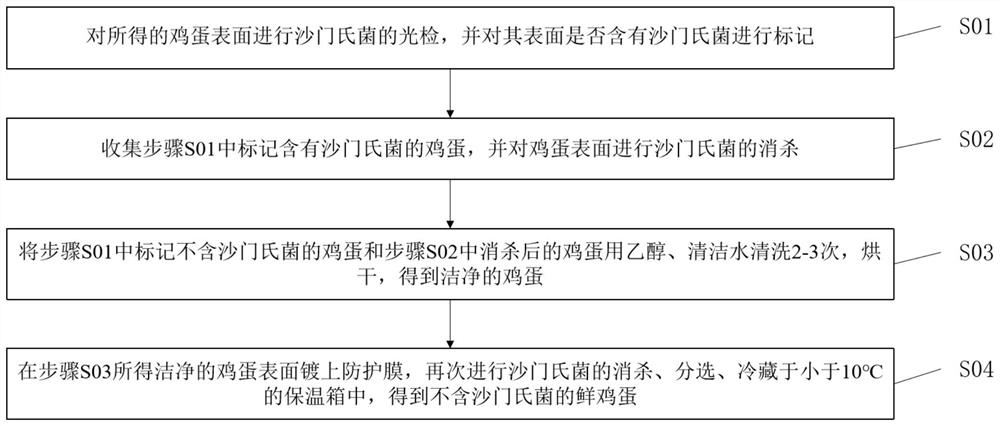

[0028] figure 1 It is a flow chart of the aseptic egg production process for Salmonella in the present invention, from which it can be seen that in the aseptic egg production process for Salmonella in the present invention, Salmonella in laying hens is monitored to eliminate Salmonella. Specifically include the following steps:

[0029] Step Ⅰ: Breeding of laying hens: Carry out the detection of Salmonella antibody to chicken flocks, select roosters and hens with Salmonella antibodies as grandmothers, breed in a clean and Salmonella-free environment, and hatch the parents; preferably with The parents of Salmonella antibodies are bred in a clean and Salmonella-free environment, the offspring are hatched and a new round of screening is performed, and the offspring with Salmonella antibodies are selected again for the next generation of breeding, and so on, to prevent Vertical transmission of Salmonella.

[0030] Step Ⅱ: Breeding of laying hens: optimize the feeding environment...

specific Embodiment 2

[0041] figure 1 It is a flow chart of the aseptic egg production process for Salmonella in the present invention, from which it can be seen that in the aseptic egg production process for Salmonella in the present invention, Salmonella in laying hens is monitored to eliminate Salmonella. Specifically include the following steps:

[0042] Step Ⅰ: Breeding of laying hens: Carry out the detection of Salmonella antibody to chicken flocks, select roosters and hens with Salmonella antibodies as grandmothers, breed in a clean and Salmonella-free environment, and hatch the parents; preferably with The parents of Salmonella antibodies are bred in a clean and Salmonella-free environment, the offspring are hatched and a new round of screening is performed, and the offspring with Salmonella antibodies are selected again for the next generation of breeding, and so on, to prevent Vertical transmission of Salmonella.

[0043] Step Ⅱ: Breeding of laying hens: optimize the feeding environment...

specific Embodiment 3

[0054] figure 1 It is a flow chart of the aseptic egg production process for Salmonella in the present invention, from which it can be seen that in the aseptic egg production process for Salmonella in the present invention, Salmonella in laying hens is monitored to eliminate Salmonella. Specifically include the following steps:

[0055] Step Ⅰ: Breeding of laying hens: Carry out the detection of Salmonella antibody to chicken flocks, select roosters and hens with Salmonella antibodies as grandmothers, breed in a clean and Salmonella-free environment, and hatch the parents; preferably with The parents of Salmonella antibodies are bred in a clean and Salmonella-free environment, the offspring are hatched and a new round of screening is performed, and the offspring with Salmonella antibodies are selected again for the next generation of breeding, and so on, to prevent Vertical transmission of Salmonella.

[0056] Step Ⅱ: Breeding of laying hens: optimize the feeding environment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com