Electrolyte for improving high-temperature performance of lithium ion battery and lithium ion battery

A lithium-ion battery, high-temperature performance technology, applied in the field of lithium-ion batteries, can solve problems such as cycle performance deterioration, achieve the effects of improving high-temperature storage and cycle performance, reducing the increase in SEI film thickness, and reducing battery internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

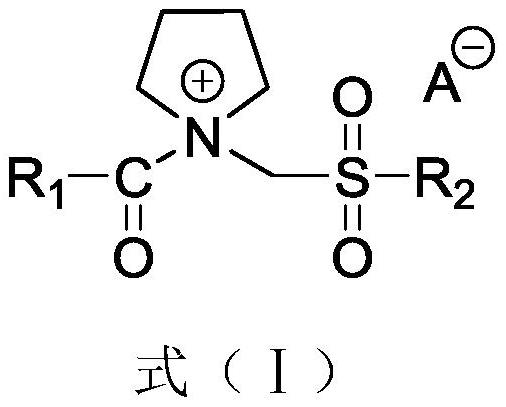

Method used

Image

Examples

preparation example Construction

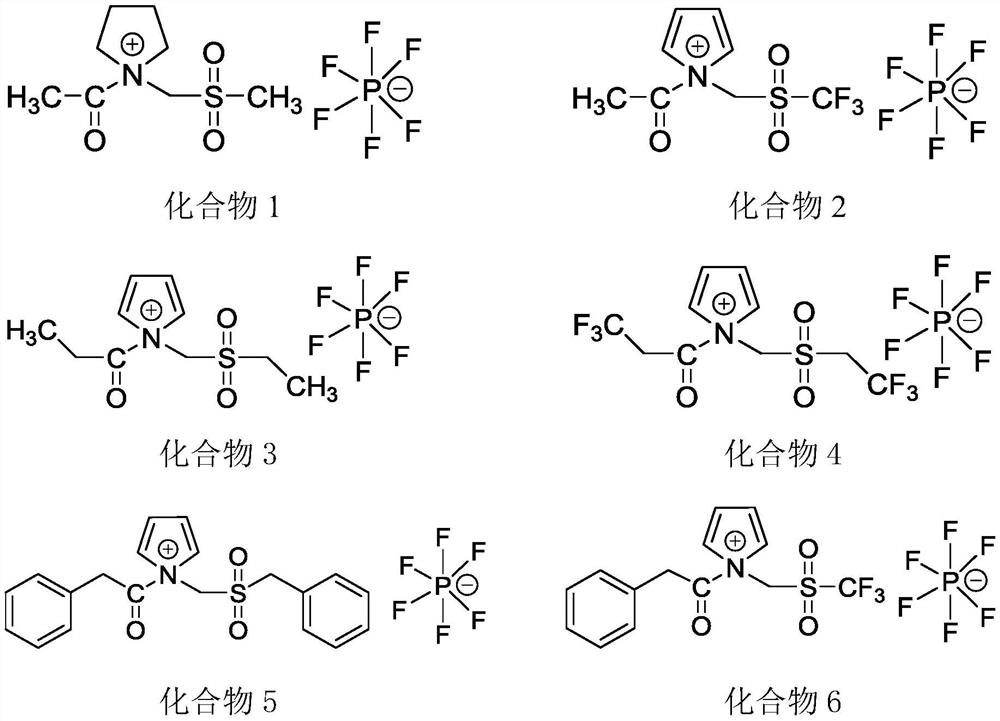

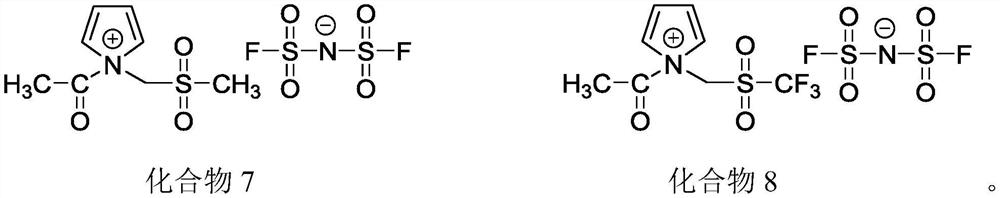

[0033] The preparation method of above-mentioned compound 1 is as follows:

[0034] S1, performing a substitution reaction between acetyl chloride and pyrrole to obtain acetylpyrrole;

[0035] S2, reacting acetylpyrrole with methylsulfonyl chloride to obtain N-acetyl-N-methylsulfonylpyrrole chloride salt;

[0036] S3. Perform ion exchange reaction between N-acetyl-N-methylsulfonylpyrrole chloride salt and potassium hexafluorophosphate to obtain compound 1N-acetyl-N-methylsulfonylpyrrole hexafluorophosphate.

[0037] The preparation method of above-mentioned compound 2 is as follows:

[0038] S1, performing a substitution reaction between acetyl chloride and pyrrole to obtain acetylpyrrole;

[0039] S2, reacting acetylpyrrole with trifluoromethanesulfonyl chloride to obtain N-acetyl-N-trifluoromethanesulfonylpyrrole chloride salt;

[0040] S3. Perform ion exchange reaction between N-acetyl-N-trifluoromethanesulfonylpyrrole chloride salt and potassium hexafluorophosphate to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com