Continuous glass fiber weather resistance testing device and testing method

A glass fiber and testing device technology, applied in the direction of measuring device, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve problems such as inability to meet customers, inability to test and evaluate the weather resistance of glass fiber yarns, and achieve a wide range of applications , The effect of preventing manual timing overtime and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

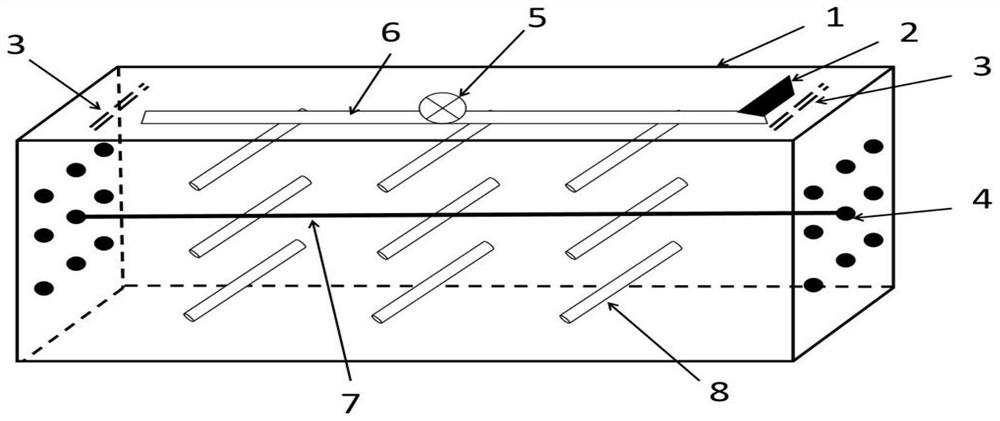

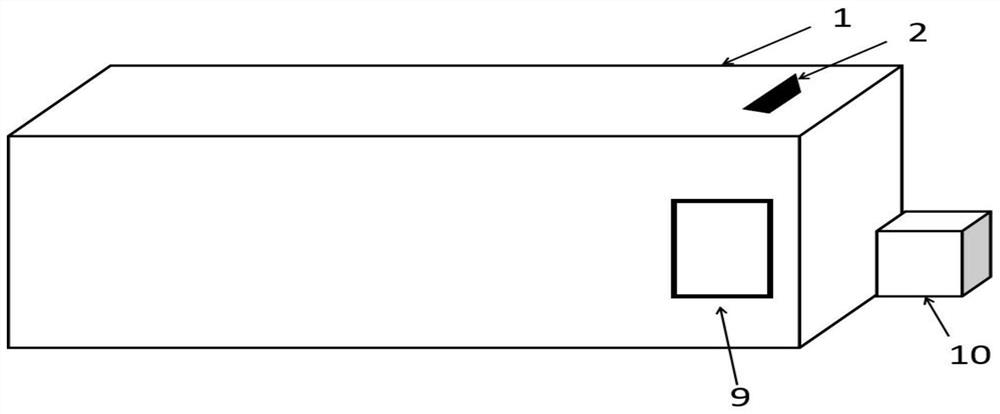

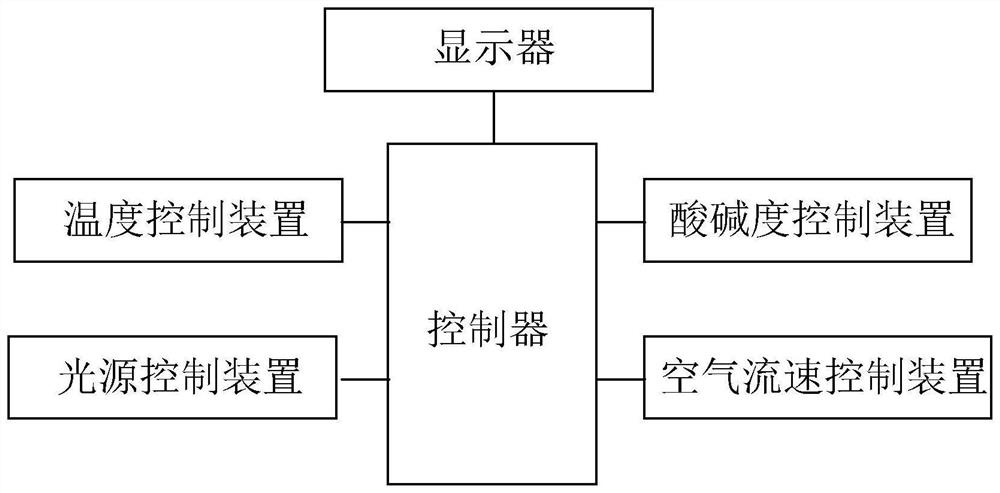

[0030] Such as Figure 1-3 As shown, a continuous glass fiber weather resistance test device according to the present invention includes a test box 1, and a yarn fixer 4 is arranged in the test box 1, and the yarn fixer 4 is used to fix the glass fiber yarn Inside the test box 1, the inside of the test box 1 is provided with a temperature control device, a light source control device, an acid-base control device and an air flow rate control device, and the outside of the test box 1 is provided with a controller and a display 9 to control The device is electrically connected to a display 9, a temperature control device, a light source control device, an acid-base control device and an air velocity control device.

[0031] There is also a non-friction yarn guide rod 8 inside the test box 1, and the friction-free yarn guide rod 8 includes a plurality to prevent the glass fiber yarns from turning over, shifting, sagging and interfering with each other.

[0032] The temperature co...

Embodiment 2

[0046]A kind of testing method of continuous glass fiber weather resistance testing device of the present invention, comprises the following steps:

[0047] Step 1: Put the glass fiber yarn at the leftmost end of the abrasion tester, draw the yarn along the tangential direction of the bobbin, and take a certain length of glass fiber yarn for sampling;

[0048] Step 2: pinch one end of the yarn by hand, pass the glass fiber yarn into the test box 1 through the frictionless yarn guide rod 8, and fix one end of the glass fiber yarn on the yarn fixing device 4;

[0049] Step 3: Tighten the glass fiber yarn at the left end, straighten the yarn, fix it with the yarn fixing device 4, and keep the glass fiber yarn level without sagging;

[0050] Step 4: Set the parameters of temperature, humidity, time, ultraviolet light source, air flow rate, acid concentration, and alkali concentration, and conduct aging and corrosion tests; set the corresponding running time, and the equipment will...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com