Test method for in-situ characterization of anisotropy of 3D printing concrete

An anisotropic, 3D printing technology, used in the preparation of test samples, the use of repetitive force/pulsation force testing material strength, measurement devices, etc. Quickly obtain test results, difficult processing of test blocks, etc., to achieve the effect of versatility and operability, easy to popularize and use, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be further described below with reference to the accompanying drawings.

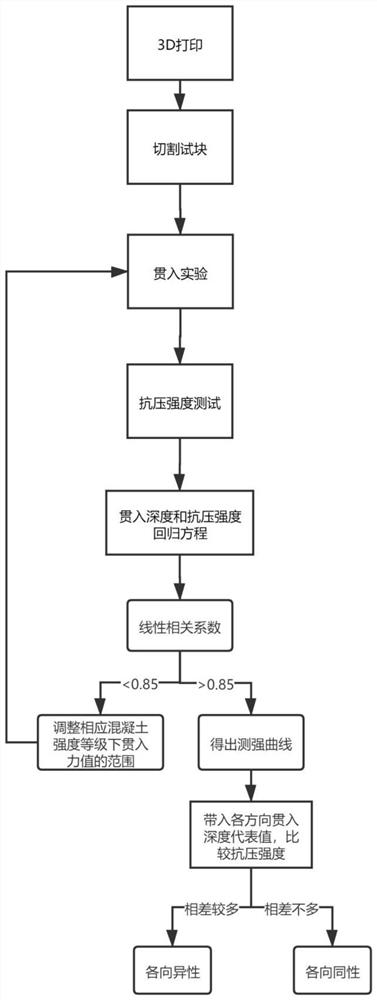

[0034] Test method for primary characterization 3D printing concrete anisotropy

[0035] Route 1: Get a 3D print concrete penetration depth of a C30 intensity level - compressive strength regression curve

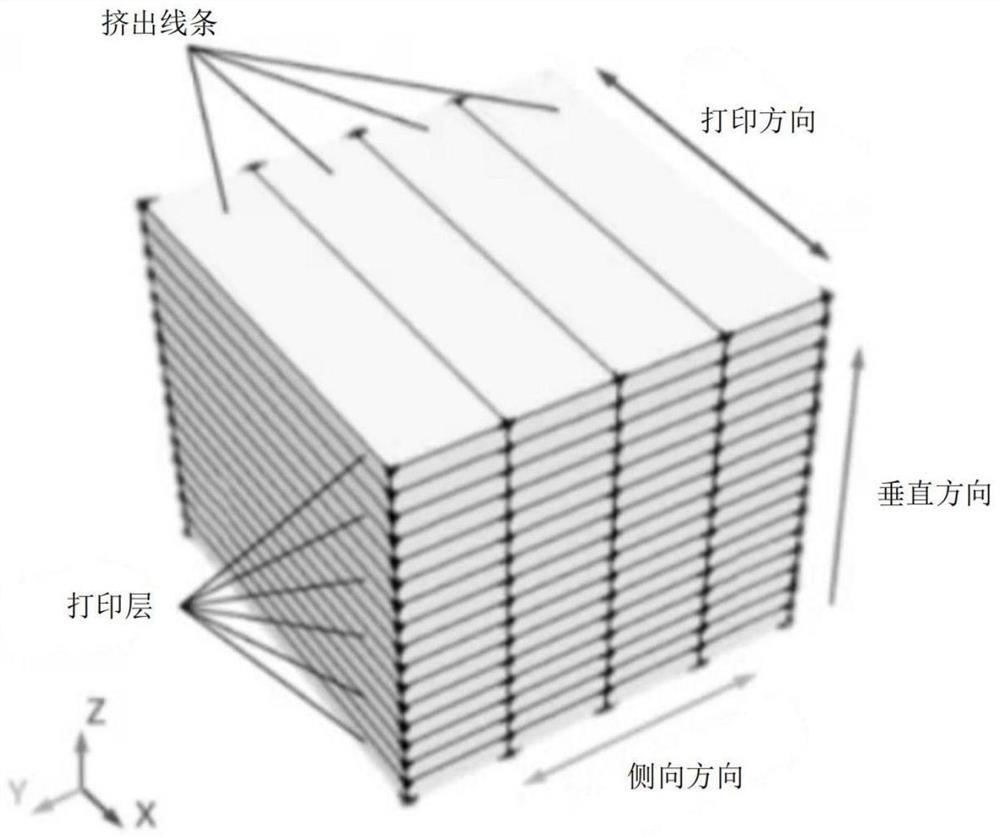

[0036] (1) Set the print nozzle diameter of 40mm, set the base speed of 0.75m 3 / h, horizontal printing speed is 10m / min, printing, intensity grade C30 same condition test block, print specifications (160-190) mm × (160-190) mm × (160-190) mm, natural maintenance 56 Day, and record the environmental temperature and humidity conditions. Take 27 pieces of test blocks.

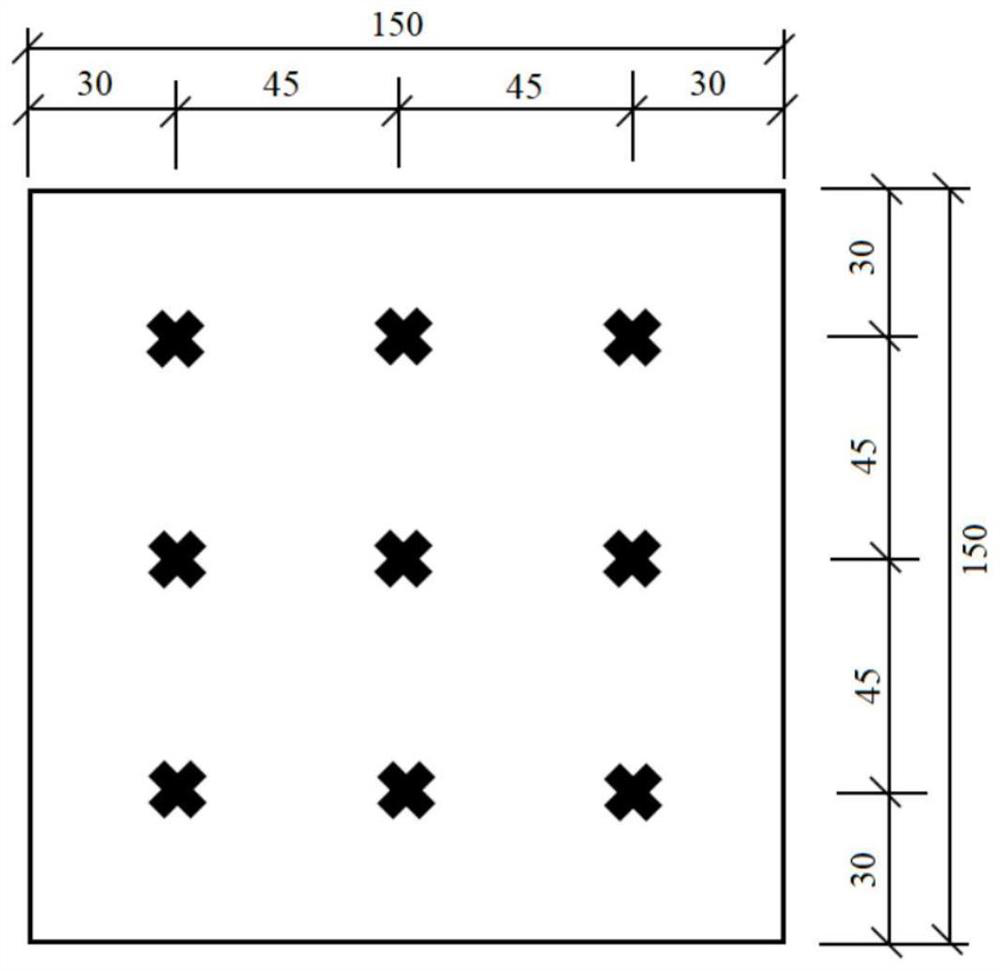

[0037] (2) After reaching the raging age, cutting and processing using high-precision processing machines, cutting the same condition test block into such as figure 2 A standard cube test block showing 150 mm × 150 mm × 150 mm.

[0038] (3) According to the direction of printing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com