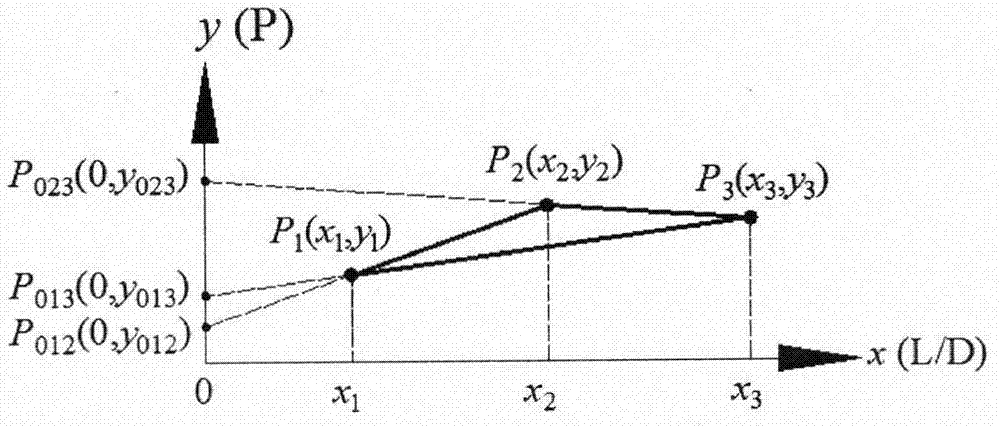

Method of representing extrusion pressure via three-point process based on Benbow-Bridgwater model

A technology of extrusion pressure and three-point method, which is used in special data processing applications, instruments, electrical digital data processing, etc. problem, to achieve the effect of improving the characterization accuracy and facilitating the optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and embodiment, the present invention will be further described:

[0033] figure 1 A schematic diagram of the Benbow-Bridgwater model explaining the process of the paste material flowing from the barrel containing the paste material to the capillary and extruded from the nozzle under the extrusion pressure, as shown in figure 1 As shown, the paste material 4 is contained in a diameter D 0 In the barrel 1, the pressure head 2 presses the paste material 4 into a nozzle (or capillary) 5 with a diameter D and a length L under the action of an extrusion pressure 3 . On entering the nozzle 5 from the barrel 1 , the paste material 4 extends in the flow direction and its cross-section decreases and exits the nozzle opening 8 at an extrusion velocity (V) 7 to form an extrudate 6 . The important feature of the capillary 5 is that the diameter D is very small, the flow of the paste material in the capillary is only laminar and not t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com