Temperature sensor and assembling method thereof

A technology of temperature sensor and assembly method, which is applied to thermometers, thermometer parts, instruments, etc., can solve problems such as hidden dangers of temperature sensing components and wires, so as to improve normal working performance, improve connection strength, and avoid short circuit or open circuit phenomenon. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

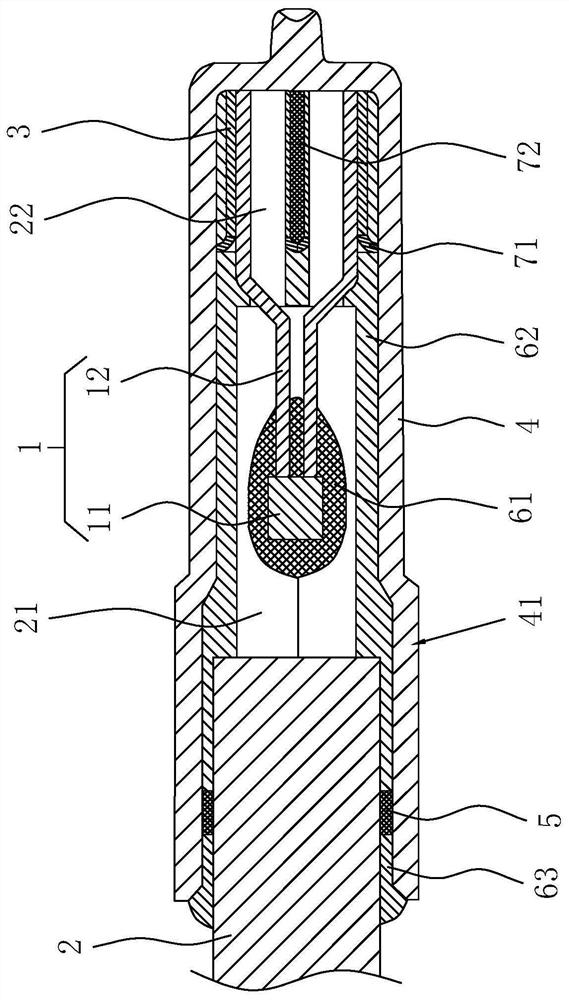

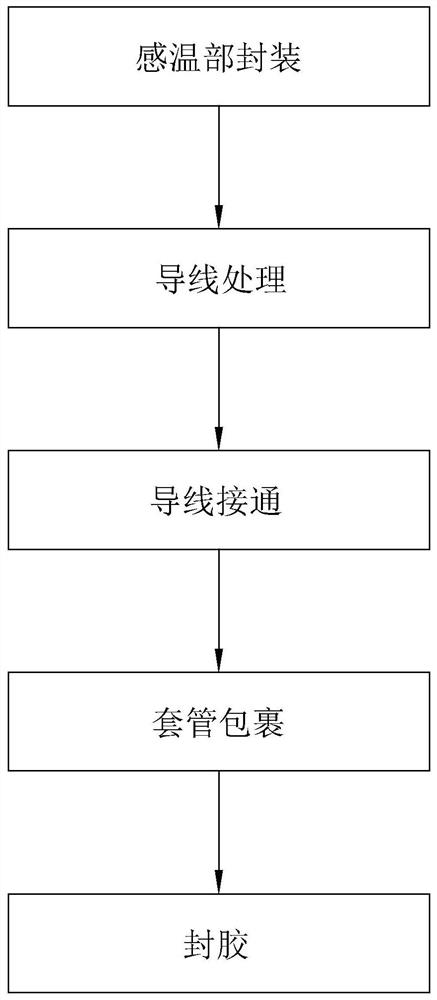

[0042] The following is attached Figure 1-2 The application is described in further detail.

[0043] The embodiment of the present application discloses a temperature sensor. refer to figure 1 , the temperature sensor includes a temperature sensing element 11, two pins 12 electrically connected to the temperature sensing element 11, the pin 12 is covered with a sheath 3 for fastening the pin 12 and one of the conductors 22 on the cable 2 , a sheath 3 corresponds to a pin 12 and a conductor 22, and the pin 12 and the conductor 22 are tightly pressed and clamped in the sheath 3, and the sheath 3 can be a copper sheath, an aluminum sheath, a lead sheath or an embedded metal layer The rubber sleeve is used to fasten the pin 12 and the conductor 22 by pressing square.

[0044] After setting in this way, the connection strength between the pin 12 and the conductor 22 is significantly improved, and it is not easy to detach in the harsh environment, effectively ensuring the conduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com