Antibacterial and antiviral plant fiber prepared from zinc chloride/urea eutectic system as well as method and application of antibacterial and antiviral plant fiber

A plant fiber, zinc chloride technology, applied in plant fiber, biochemical fiber treatment, fiber treatment and other directions, can solve the problems of destroying fiber strength, uneven distribution of zinc ions, not easy reduction, etc., to increase adsorption capacity, antibacterial resistance Virus effect is remarkable, the effect of high adhesion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

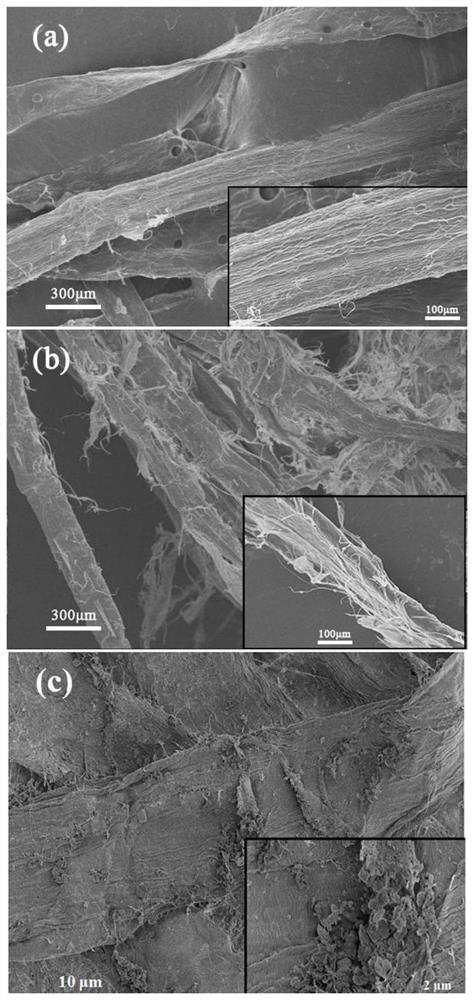

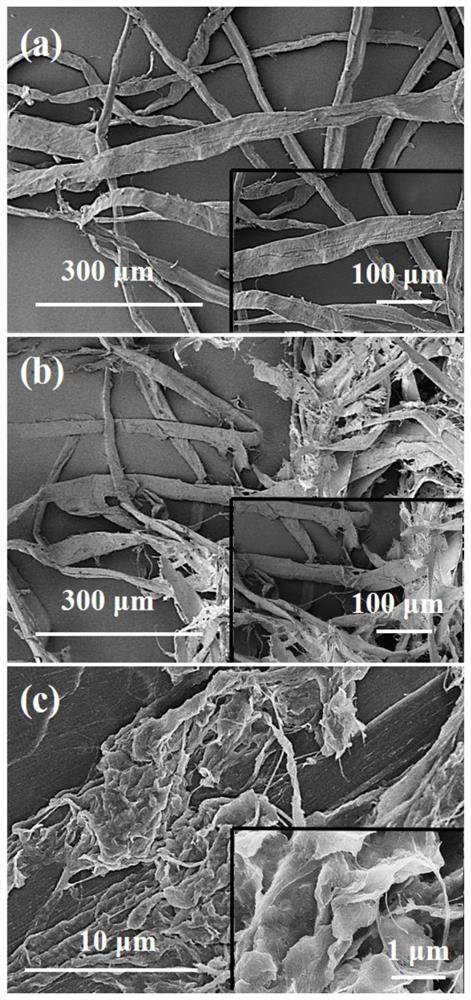

[0073] A method for preparing antibacterial and antiviral plant fibers with zinc chloride / urea eutectic system, comprising the following steps:

[0074] (1) Weigh 30 grams (dry mass) of bleached spruce softwood chemical pulp, add 970 mL of deionized water to make the concentration 3%, soak for 4 hours at a temperature of 20 ° C, then add 500 mL of deionized water to adjust the fiber concentration Dissociate at a temperature of 20°C with a standard fiber disintegrator, and rotate the propeller at 20,000 revolutions, so that the plant fibers are evenly dispersed into a single fiber state.

[0075] (2) The decomposed plant fiber obtained in step (1) is concentrated to a concentration of 10% with a Buchner funnel, placed in a PFI mill for mechanical beating, the beating temperature is 20°C, and the beating concentration is 10%. , the number of beating revolutions is 20,000 rpm, and the beating degree of the plant fiber after beating is 80.4°SR, thereby obtaining the plant fiber wi...

Embodiment 2

[0082] A method for preparing antibacterial and antiviral plant fibers with zinc chloride / urea eutectic system, comprising the following steps:

[0083] (1) Weigh 30 grams (absolutely dry mass) of bleached hardwood pulp chemical pulp, add 1470 mL of deionized water to make the concentration 2%, soak at a temperature of 20 ° C for 6 hours, and then use a standard fiber disintegrator at 20 ° C The dissociation is carried out at a certain temperature, and the rotation speed of the propeller is 20,000 revolutions, so that the plant fibers are evenly dispersed into a single fiber state.

[0084] (2) The decomposed plant fiber obtained in step (1) is concentrated to a concentration of 10% with a Buchner funnel, placed in a PFI mill for mechanical beating, the beating temperature is 20°C, and the beating concentration is 10%. , the number of beating revolutions is 30,000 rpm, and the degree of beating of the plant fiber after beating is 84.4°SR, thereby obtaining the plant fiber with...

Embodiment 3

[0091] A method for preparing antibacterial and antiviral plant fibers with zinc chloride / urea eutectic system, comprising the following steps:

[0092] (1) Weigh 30 grams (dry mass) of bleached hardwood pulp chemical pulp, add 1470 mL of deionized water to make the concentration 2%, soak at a temperature of 30 °C for 6 hours, and then use a standard fiber disintegrator at 30 °C The dissociation is carried out at a certain temperature, and the rotation speed of the propeller is 30,000 revolutions, so that the plant fibers are evenly dispersed into a single fiber state.

[0093] (2) The decomposed plant fiber obtained in step (1) is concentrated to a concentration of 10% with a Buchner funnel, and placed in a Jokro mill for mechanical beating. The beating temperature is 30° C., and the beating concentration is 10%. , the number of beating revolutions is 40,000 rpm, and the degree of beating of the plant fiber after beating is 89.8°SR, thereby obtaining the plant fiber with a di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com