Anti-hydrogen material and preparation method thereof

A technology for hydrogen materials and raw materials, applied in the field of hydrogen-resistant materials and their preparation, can solve the problems of high inclusion content, high hydrogen content, poor room temperature performance, etc., and achieves a wide source of raw materials, low production cost, and good thermal processing performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

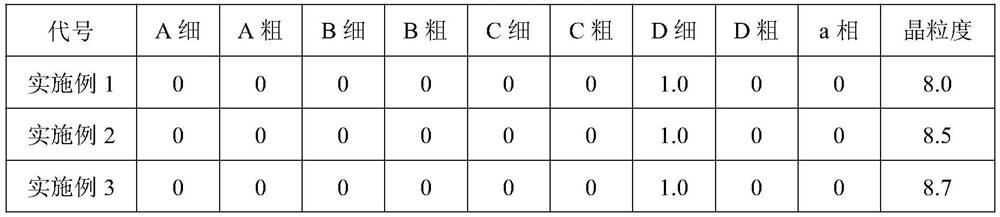

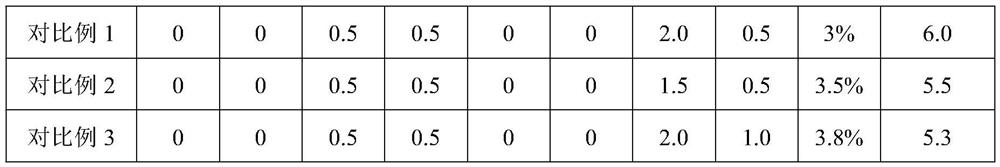

Examples

Embodiment 1

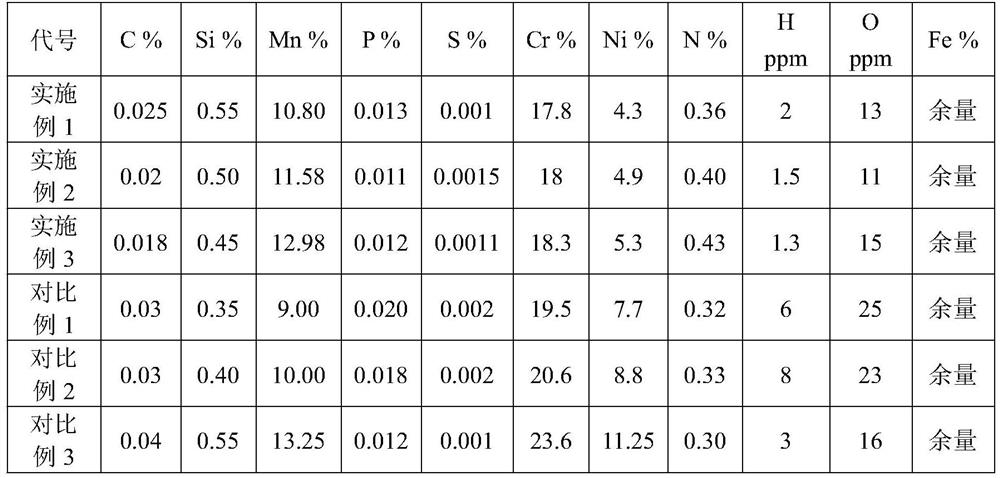

[0038] The chemical element composition of the anti-hydrogen material is shown in Table 1, and its preparation method follows the following steps:

[0039] (1) Smelting: Use electric furnace + AOD furnace + LF furnace + VD furnace to smelt the required element raw materials. The casting temperature during smelting is 1480 ° C, and the dissolved hydrogen content in the molten steel is controlled to be 18ppm; when the Ca content in the molten steel is low at 5×10 -12 In ppm, Mg is added to the molten steel so that the Mg content in the molten steel reaches 8×10 -6 ~1×10 -5 Between ppm;

[0040] (2) LF furnace is used for refining deoxidation, and VD furnace is used for vacuum dehydrogenation to reduce the hydrogen content in molten steel to below 3ppm;

[0041] (3) Electroslag: The electrode rod of step (1) is carried out electroslag remelting, and the composition of described electroslag is counted as: CaF 2 :Al 2 o 3 :CaO:SiO 2 :MgO=52:16:20:9:3, using protective atmosp...

Embodiment 2

[0045] The chemical element composition of the anti-hydrogen material is shown in Table 1, and its preparation method follows the following steps:

[0046] (1) Smelting: Use electric furnace + AOD furnace + LF furnace + VD furnace to smelt the required element raw materials. The casting temperature during smelting is 1500 ° C, and the dissolved hydrogen content in the molten steel is controlled to be 8ppm; when the Ca content in the molten steel is low at 5×10 -12 In ppm, Mg is added to the molten steel so that the Mg content in the molten steel reaches 8×10 -6 ~6×10 -5 Between ppm;

[0047] (2) AOD furnace is used for oxygen blowing decarburization, and VD furnace is used for vacuum dehydrogenation to reduce the hydrogen content in molten steel to below 3ppm;

[0048] (3) electroslag: add electroslag to the molten steel of step (1) and carry out smelting, and the composition of described electroslag is counted as: CaF 2 :Al 2 o 3 :CaO:SiO 2 :MgO=52:16:20:9:3, using non...

Embodiment 3

[0052] The chemical element composition of the anti-hydrogen material is shown in Table 1, and its preparation method follows the following steps:

[0053] (1) Smelting: Use electric furnace + AOD furnace + LF furnace + VD furnace to smelt the required elemental raw materials. The casting temperature during smelting is 1520°C, and the dissolved hydrogen content in the molten steel is controlled to be 10-12ppm;

[0054] (2) AOD furnace is used for oxygen blowing decarburization, and VD furnace is used for vacuum dehydrogenation to reduce the hydrogen content in molten steel to below 3ppm;

[0055] (3) electroslag: add electroslag to the molten steel of step (1) and carry out smelting, and the composition of described electroslag is counted as: CaF 2 :Al 2 o 3 :CaO:SiO 2 :MgO=52:16:20:9:3, using protective atmosphere electroslag (inert gas is introduced into the electroslag process to form a protective atmosphere above the slag pool, isolate the air, and prevent the hydrogen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com