Hydrogen-rich reaction system coupled with coal gasification and carbon removal method for coal gasification

A reaction system and coal gasification technology, applied in the field of coal gasification, can solve the problems of high energy consumption and poor decarbonization effect, and achieve the effects of improving production efficiency, occupying less space, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

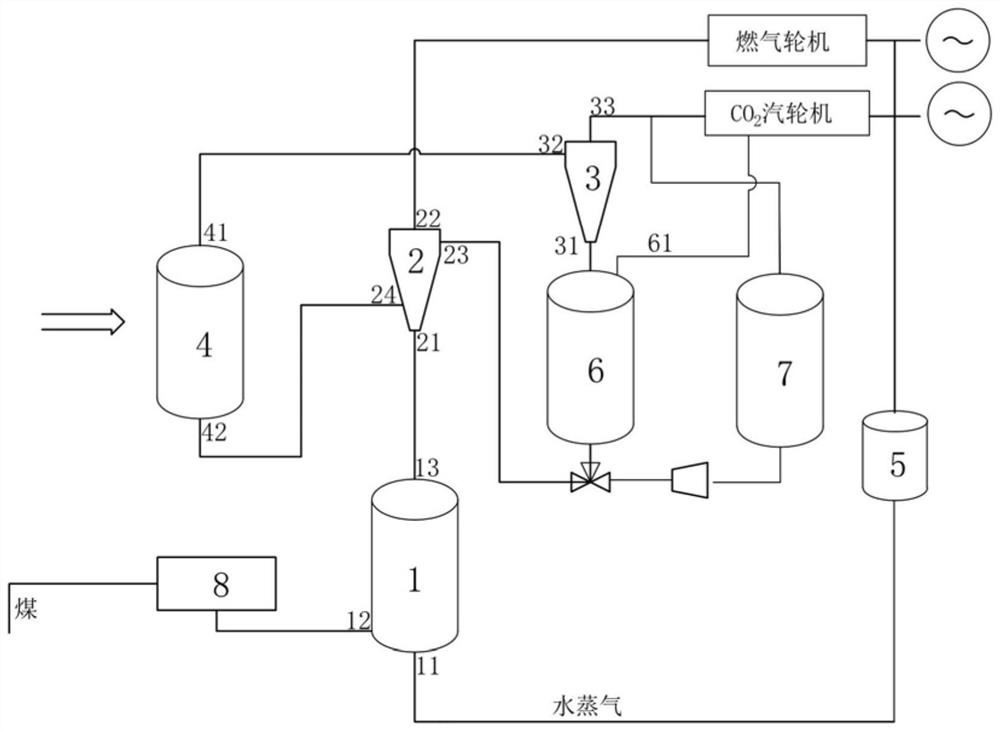

[0041] to combine Figure 1-Figure 2 As shown, the embodiment of the present invention provides a hydrogen-rich reaction system coupled with coal gasification, including:

[0042] A coal gasification device 1 is provided with a steam inlet 11 and a coal inlet 12 at the bottom, and a synthesis gas outlet 13 at the top; the synthesis gas includes water gas and water vapor; the coal gasification device 1 is suitable for generating coal gas with water vapor as a gasification agent Chemical reaction;

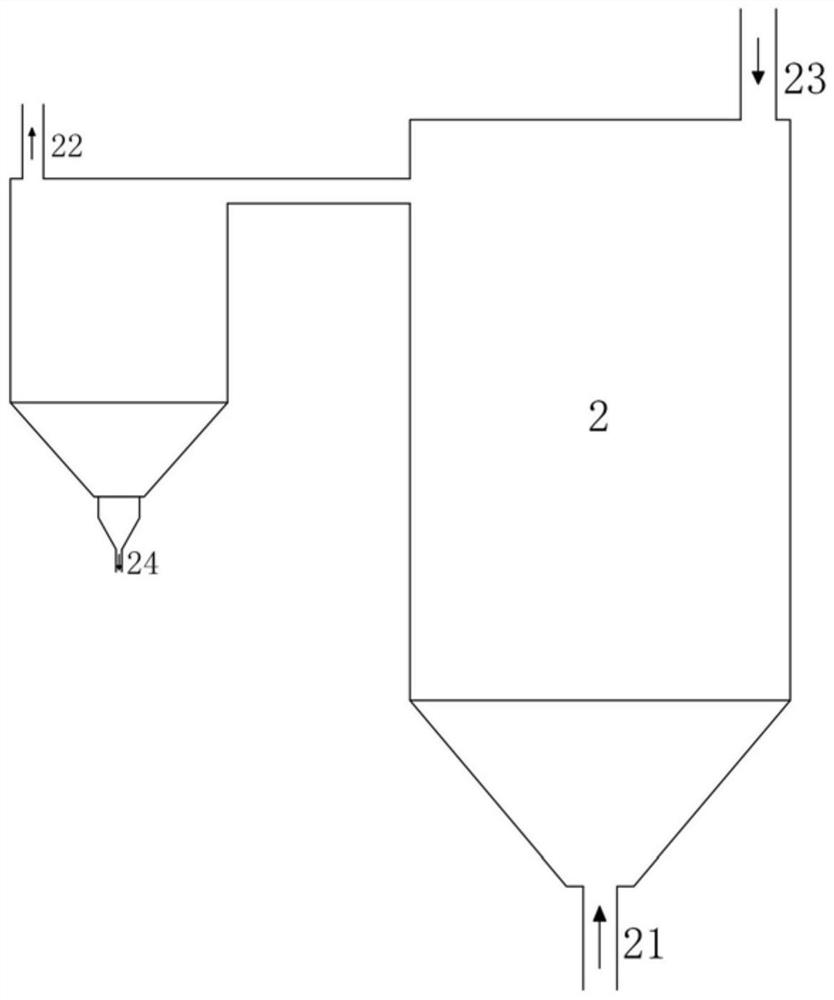

[0043]A hydrogen-rich reactor 2, the bottom of which is provided with a synthesis gas inlet 21 and a first solid phase outlet 24, the synthesis gas inlet 21 communicates with the synthesis gas outlet 13, and the hydrogen-rich reactor 2 is also provided with The first gas phase discharge port 22 and the first solid phase feed port 23; the hydrogen-rich reactor 2 is suitable for hydrogen-rich reaction; the first gas phase discharge port 22 is suitable for discharging the generated H ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com