High-wear-resistance organic silicon modified polyurethane elastomer and preparation method thereof

A polyurethane elastomer and polyurethane prepolymer technology, applied in the field of polyurethane application, can solve the problems of increasing compatibility, limited improvement of wear resistance, and not greatly increasing reaction temperature and reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

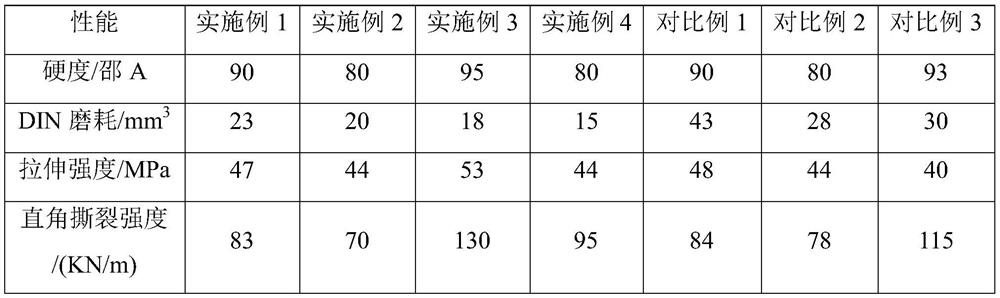

Examples

Embodiment 1

[0037] A highly wear-resistant organosilicon-modified polyurethane elastomer and a preparation method thereof, comprising the following steps:

[0038] (1) Preparation of Silicone Modified Polyurethane Prepolymer

[0039] Step 1: React 11.3g of PE-2020, 45.2g of hydroxyl-terminated polysiloxane with a hydroxyl value of 74.8mgKOH / g, 4.5g of KH560, and 43.5g of TDI-100 at 85°C for 40min;

[0040] Step 2: After the isocyanate content reaches the design value of 18%, the temperature of the reaction system is lowered to 60°C, and after adding 133.7g of PE-2020, the temperature is raised to 85°C again, and the reaction is continued for 180 minutes under the same reaction conditions. The vacuum degree for removing air bubbles is ≤-0.095MPa, and an organosilicon-modified polyurethane prepolymer with an isocyanate content of 4.3% is obtained.

[0041] (2) Preparation of silicone-modified polyurethane elastomer

[0042] 100g of polyurethane prepolymer and 12.5g of melted MOCA were mix...

Embodiment 2

[0044] A highly wear-resistant organosilicon-modified polyurethane elastomer and a preparation method thereof, comprising the following steps:

[0045] (1) Preparation of Silicone Modified Polyurethane Prepolymer

[0046] Step 1: React 46.0g of PE-4040, 20.0g of hydroxyl-terminated polysiloxane with a hydroxyl value of 28mgKOH / g, 1.0g of KH550, and 34.0g of TDI-100 at 87°C for 60 minutes;

[0047]Step 2: After the isocyanate content reaches 15% of the design value, the temperature of the reaction system is lowered to 65°C, and after adding 22.9g of PE-4040, the temperature rises to 85°C again, and the reaction is continued for 180 minutes under the same reaction conditions. The vacuum degree for removing air bubbles is ≤-0.095MPa to obtain a silicone-modified polyurethane prepolymer with an isocyanate content of 3.0%.

[0048] (2) Preparation of silicone-modified polyurethane elastomer

[0049] 100g of polyurethane prepolymer and 8.6g of melted MOCA were mixed evenly at 85°C...

Embodiment 3

[0051] A highly wear-resistant organosilicon-modified polyurethane elastomer and a preparation method thereof, comprising the following steps:

[0052] (1) Preparation of Silicone Modified Polyurethane Prepolymer

[0053] The first step: 9.6g of PE-2020, 22.4g of hydroxyl-terminated polysiloxane with a hydroxyl value of 112.2mgKOH / g, 1.7g of 1076 antioxidant, 2.2g of KH560, 54.4g of MDI-100 and 13.6g of liquefied MDI was reacted at 75°C for 60min;

[0054] Step 2: After the isocyanate content reaches 20% of the design value, the temperature of the reaction system is lowered to 60°C, and after adding 80.6g of PE-2020, the temperature is raised to 85°C again, and the reaction is continued for 120 minutes under the same reaction conditions. The vacuum degree for removing air bubbles is ≤-0.095 MPa to obtain a silicone-modified polyurethane prepolymer with an isocyanate content of 9.0%.

[0055] (2) Preparation of silicone-modified polyurethane elastomer

[0056] 100g of polyur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com