Energy-saving and environment-friendly waste PET material crushing and recycling equipment

An energy-saving, environmental protection, and recycling equipment technology, which is applied in the direction of mechanical material recycling, plastic recycling, recycling technology, etc., can solve problems such as consuming a long time, reducing the efficiency of crushing and recycling waste PET materials, and increasing labor intensity of workers, etc., to achieve reduction wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

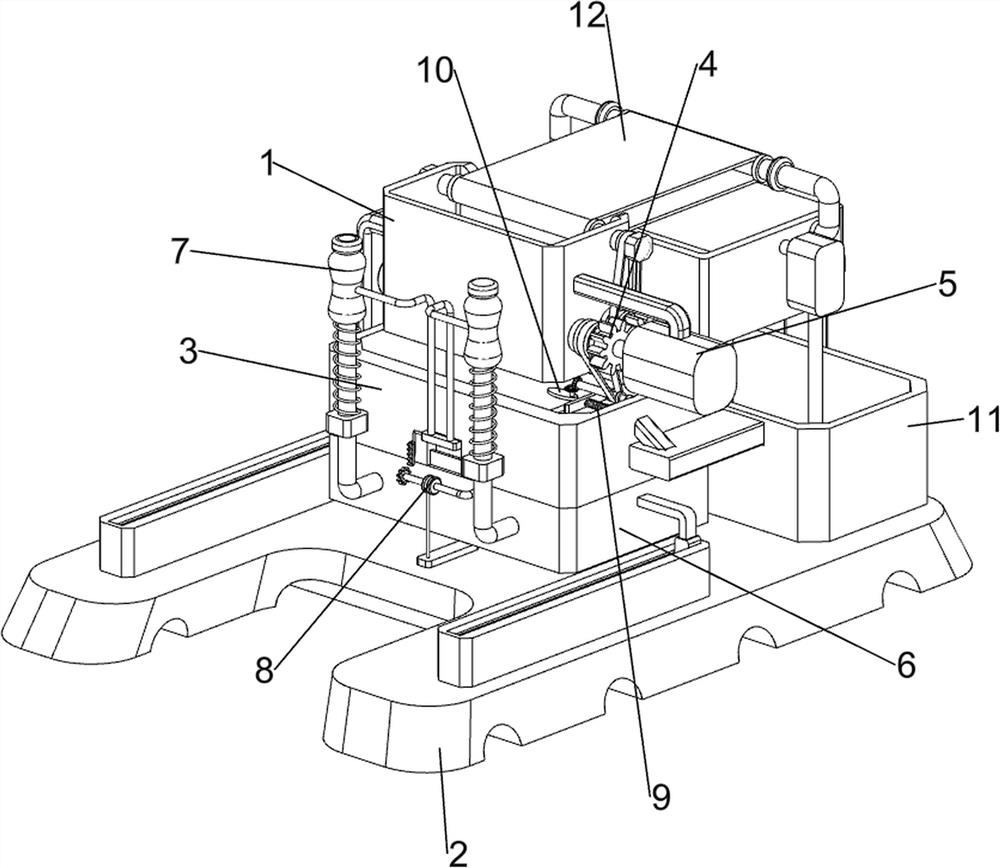

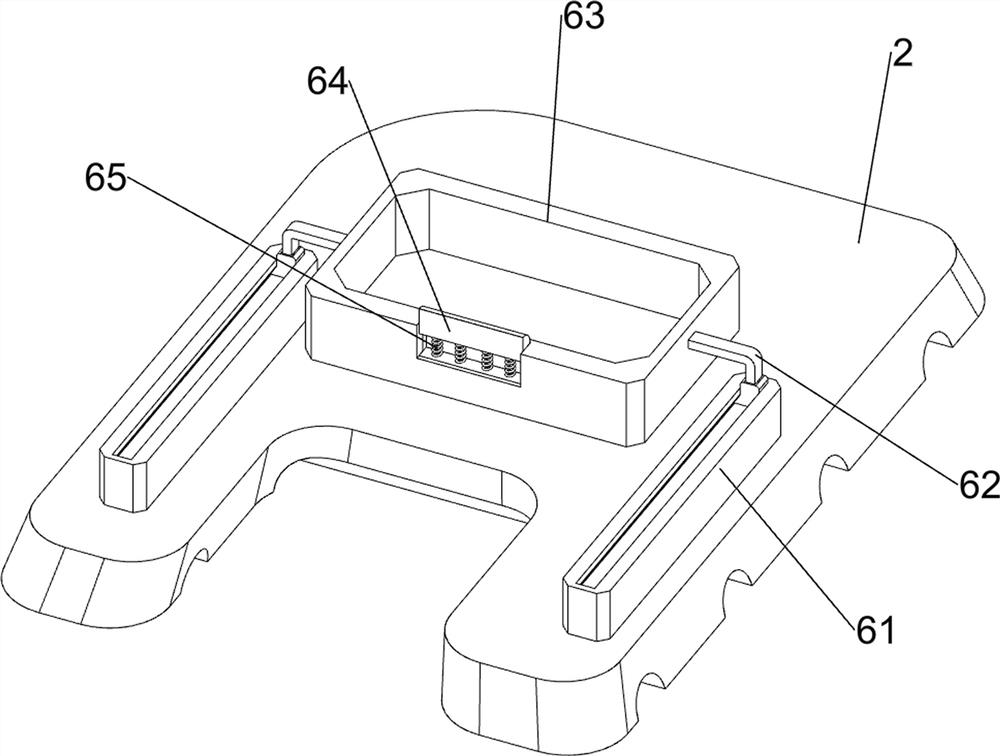

[0067] A kind of waste PET material crushing and recycling equipment for energy saving and environmental protection, such as Figure 1-3As shown, it includes a crushing box 1, a support plate 2, a water outlet frame 3, a crusher 4, a motor 5, a discharge fixing mechanism 6, and a driving discharge mechanism 7. The upper and middle parts of the support plate 2 are provided with a water outlet frame 3, and the water outlet frame 3 There is a crushing box 1 on the left side of the upper part of the outer wall. The crushing box 1 is located above the water outlet frame 3. The front and rear sides of the crushing box 1 are rotatably equipped with a crusher 4. A motor 5 is installed on the upper right side of the outer wall of the crushing box 1. The output of the motor 5 The shaft is connected to the breaker 4 on the front side, a discharge fixing mechanism 6 is connected between the water outlet frame 3 and the support plate 2, a driving discharge mechanism 7 is connected between t...

Embodiment 2

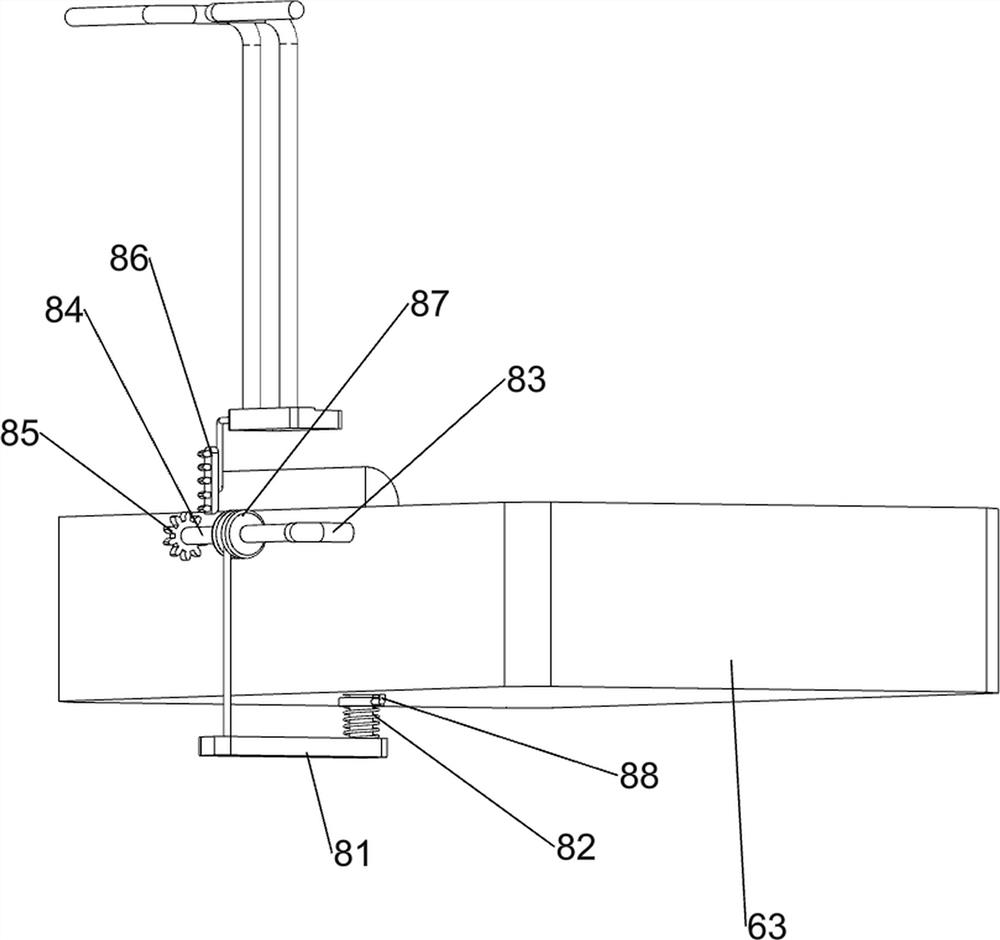

[0074] On the basis of Example 1, such as Figure 4-8 Shown, also includes drainage mechanism 8, and drainage mechanism 8 also includes water blocking plate 81, the 3rd spring 82, the 2nd strut bar 83, the 1st rotating shaft 84, the 3rd spur gear 85, spur rack 86, pull cord 87 and the third support rod 88, the lower part of the outer wall of the discharge frame 63 is provided with a third support rod 88, the third support rod 88 is slidably provided with a water blocking plate 81, and the water blocking plate 81 is slidably connected with the discharge frame 63, The water blocking plate 81 is wound with a third spring 82, the third spring 82 is connected between the water blocking plate 81 and the third support rod 88, the upper side of the front part of the outer wall of the discharge frame 63 is provided with a second support rod 83, the second The support rod 83 is provided with a first rotating shaft 84 in rotation, the left side of the first rotating shaft 84 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com