Non-fixed cathode electrolytic machining device

A cathode electrolysis and processing device technology, which is applied in the direction of electric processing equipment, electrochemical processing equipment, processing electrodes, etc., can solve the problem that it is difficult to achieve high-precision electrolytic processing on the inner surface of the casing, so as to reduce stray corrosion and ensure Machining accuracy, the effect of ensuring the airtight state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

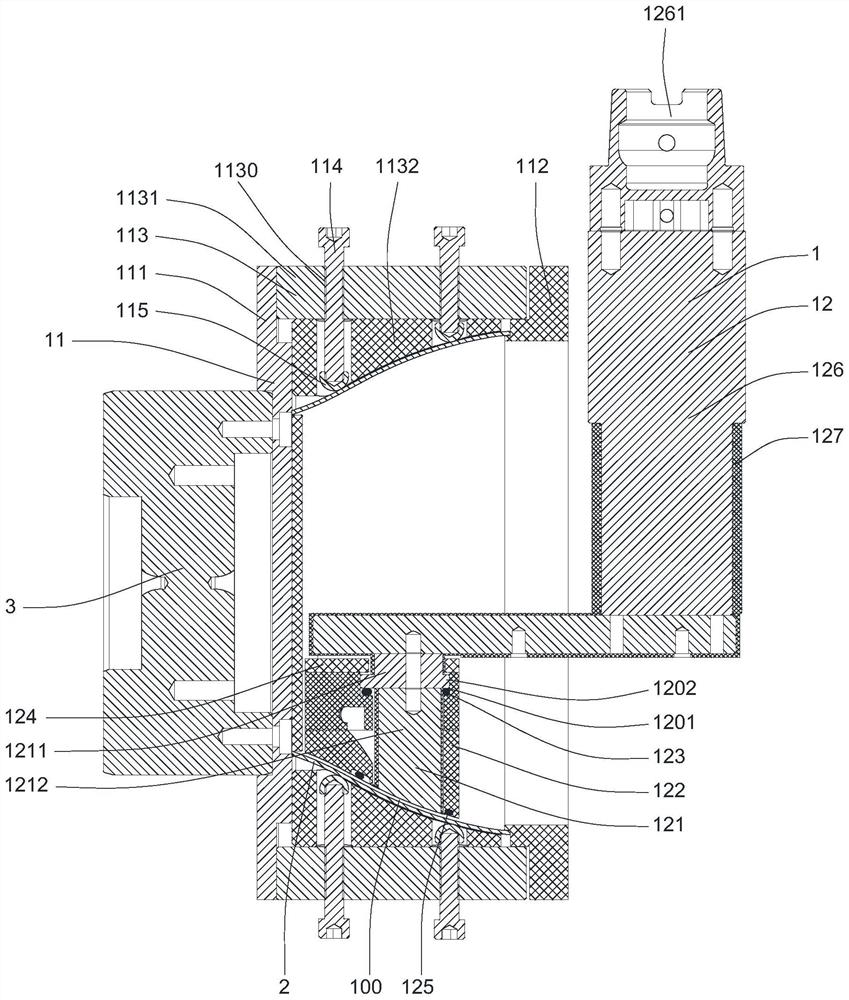

[0026] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

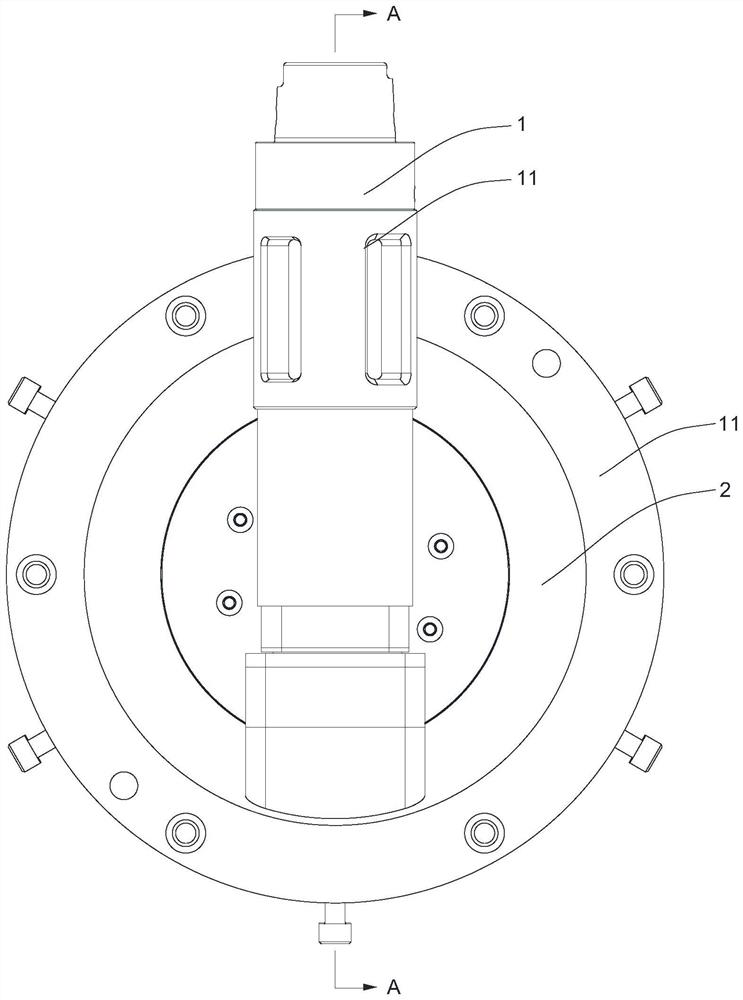

[0027] Figure 2 to Figure 5 Commonly shown is the non-fixed cathode electrolytic machining device 1 provided by the embodiment of the present invention, which is used for electrolytic machining the inner surface of the casing of an aero-engine, and can complete the machining of the casing cavity with high precision and high efficiency.

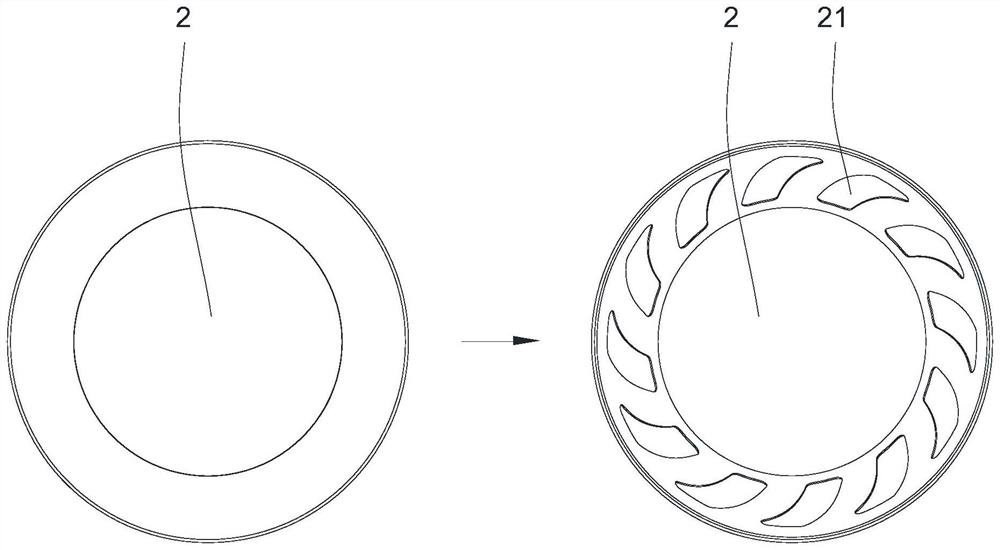

[0028] exist figure 1 shows a casing 2 suitable for the non-fixed cathode electrolytic processing device 1, the casing 2 needs to process a plurality of cavities 21 on the inner surface, and a plurality of cavities 21 along the machine The circumferential equidistant arrangement of box 2.

[0029] Please combine figure 2 and image 3 , the non-fixed cathode electrolytic processing device 1 includes an anode clamping mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com