Dry cleaning device

A technology of dry cleaning and cleaning tanks, which is applied in the direction of explosion generating devices, abrasive feeding devices, used abrasive processing devices, etc., and can solve problems such as leakage of compressed gas or cleaning media

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0110] Hereinafter, an embodiment of the present invention will be described.

[0111] Structure

[0112] First, the structure of a dry cleaning device in the embodiment of the present invention will be described.

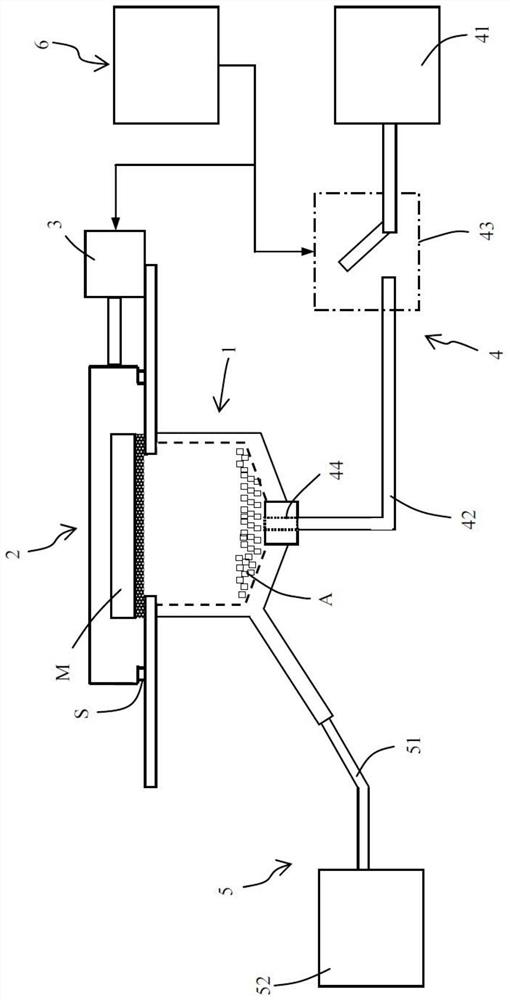

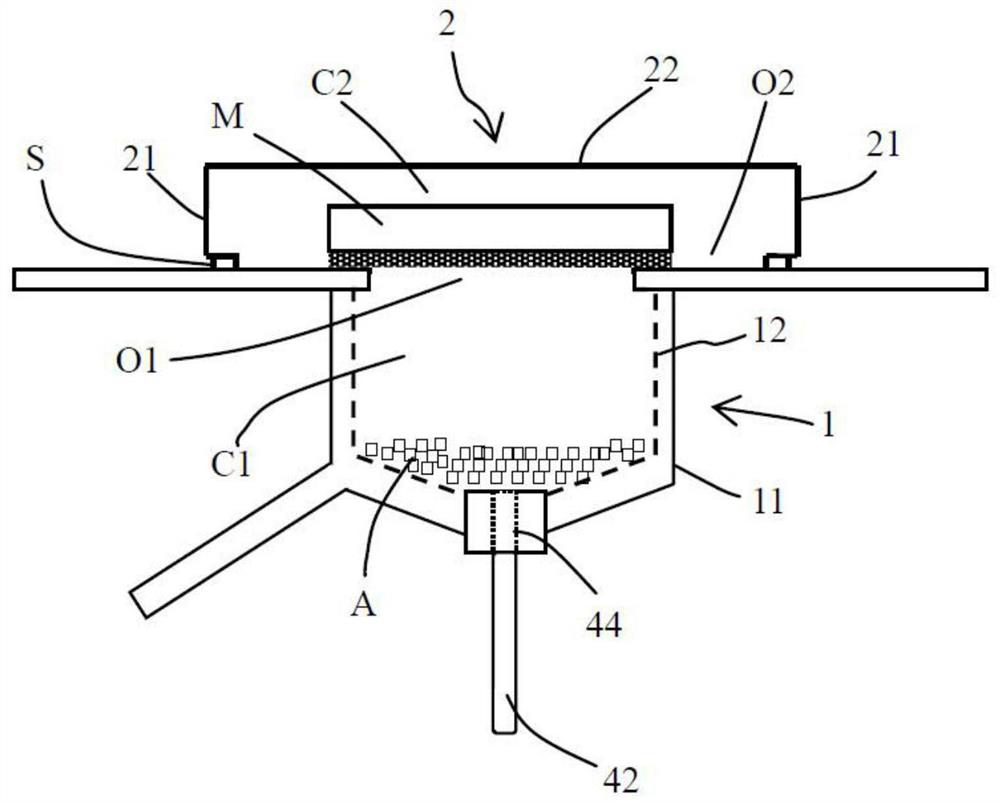

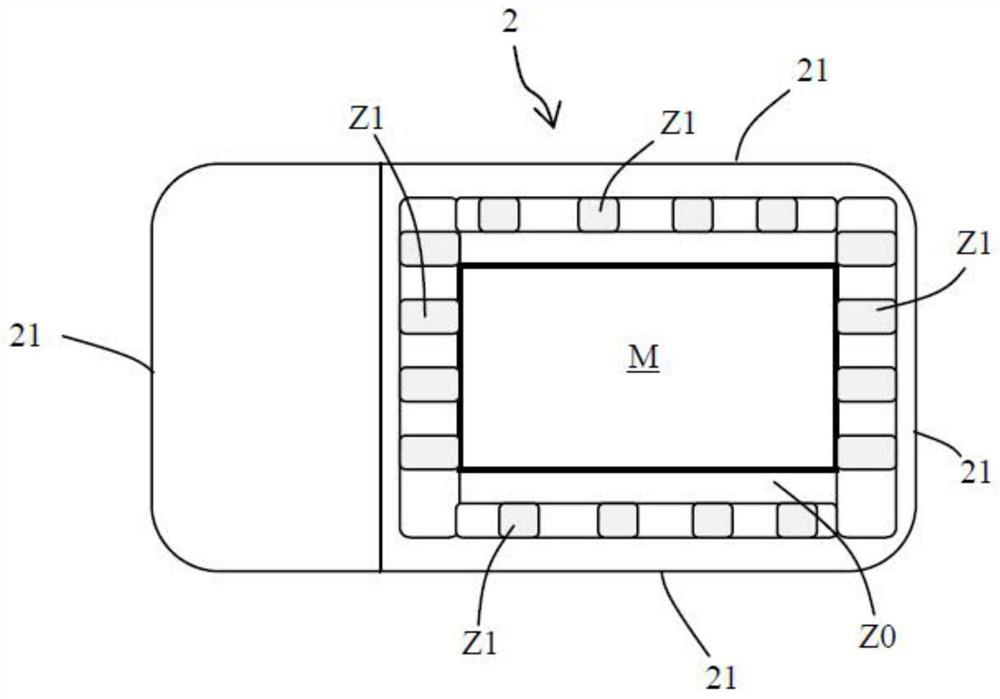

[0113] figure 1 It is a schematic view showing the overall configuration of a dry cleaning device in an embodiment of the present invention. figure 2 It is a schematic diagram showing the cleaning tank and the expansion tank of the dry cleaning device in the embodiment. image 3 It is a top plan view showing the expansion groove of the dry cleaning device in the embodiment. Figure 4 It is a schematic diagram showing the arrangement of the gas supply unit of the dry cleaning device in the embodiment.

[0114] like figure 1 As shown, the dry cleaning device has a cleaning tank 1, a spread groove 2, a drive unit 3, a gas supply unit 4, a detecting unit, a fouling recovery unit 5, and a control unit 6.

[0115] like figure 2 As shown, the cleaning tank 1 has an outer casin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com