Heat exchanger and manufacturing method thereof

A technology for heat exchangers and heat transfer fins, used in heat exchanger sealing devices, heat exchange equipment, heat exchanger types, etc., can solve problems such as unsuitable sealing and deformation, and achieve easy and reliable control of poor coating. Effect of airtight retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

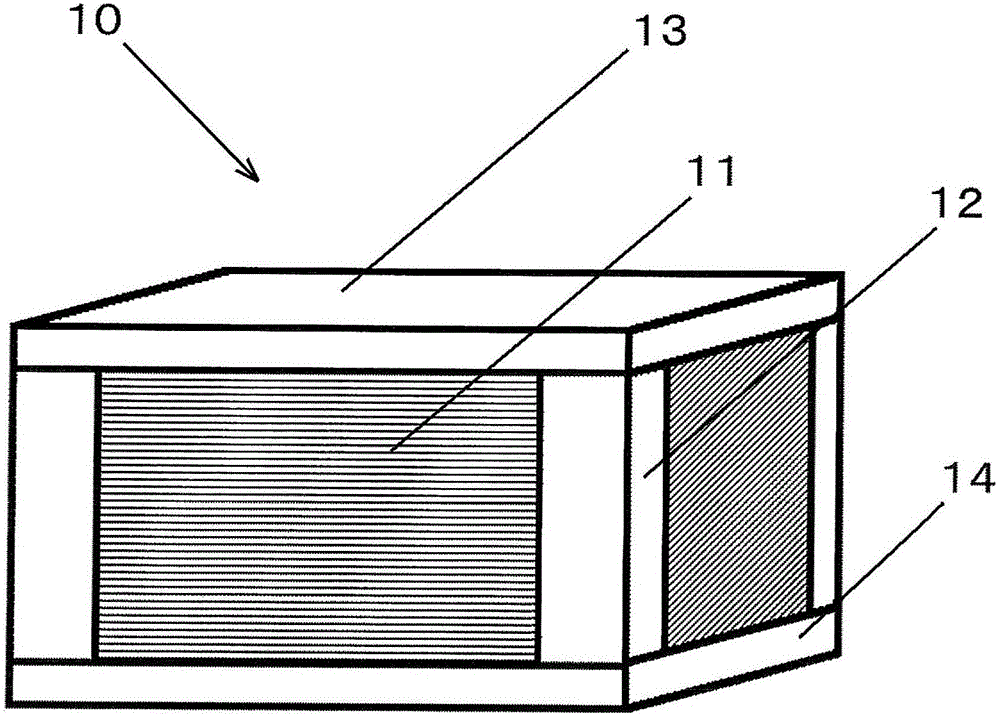

[0041] Below, refer to Figure 1 to Figure 8 The heat exchanger according to the first embodiment of the present invention will be described. The heat exchange laminate 11 is formed by laminating a plurality of heat transfer sheets 16 such as aluminum sheets. In addition, the heat exchange laminate 11 is assembled to a housing by bolts, rivets, or the like, and the housing is composed of a corner member 12, a top plate 13, and a bottom plate 14 made of metal. In addition, as the heat transfer sheet 16, in addition to the aluminum sheet, especially when the air for heat exchange contains corrosive substances, a corrosion-resistant coated aluminum sheet or stainless steel sheet can also be used. Corrosive metal sheet.

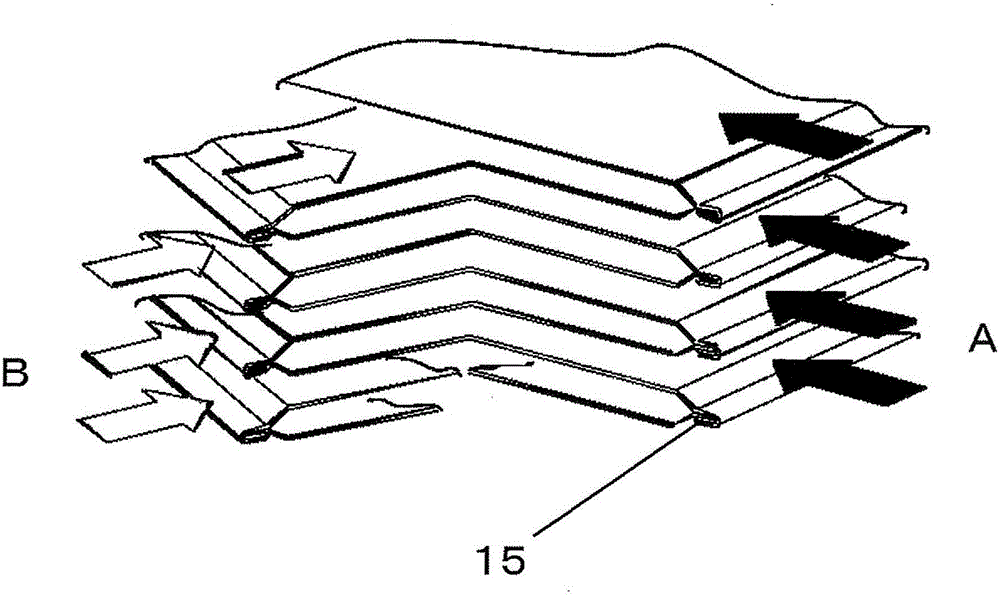

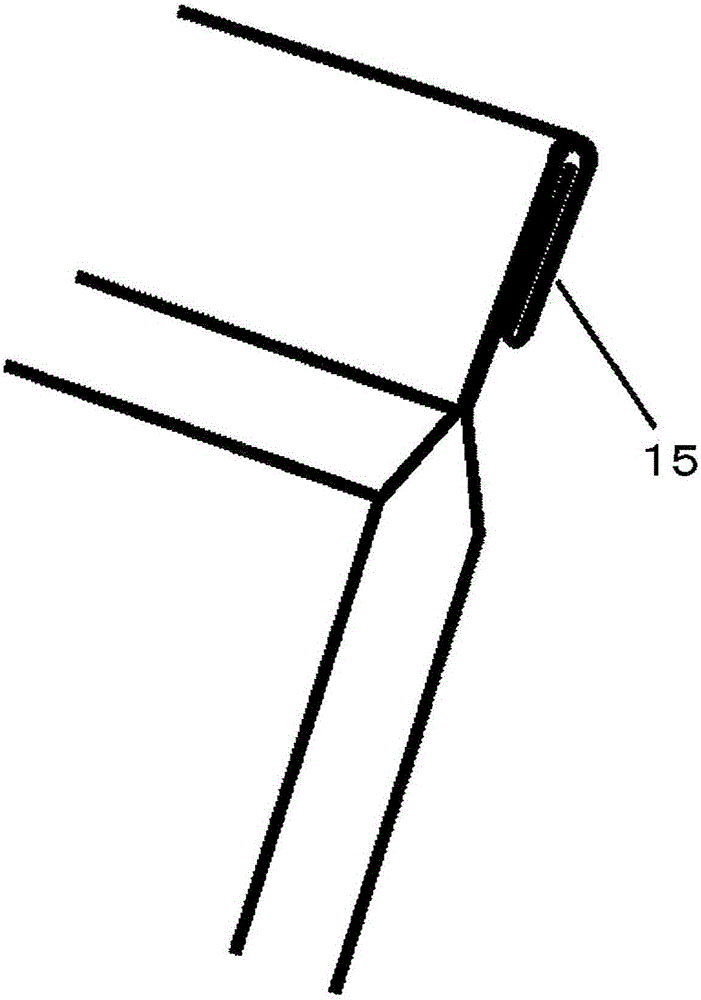

[0042] figure 2 A schematic diagram of the heat exchange laminate 11 is shown. The airflow A of the return air and the airflow B of the outside air are completely isolated by the heat transfer sheet, and no gas transfer occurs. In addition, such as image 3 As ...

no. 2 approach

[0053] Picture 9 The heat exchanger of another embodiment is shown. This heat exchanger is a cross-type heat exchanger in which flat heat transfer fins and heat transfer fins processed in a wave form as a spacer are stacked alternately and orthogonally. In this heat exchanger, as in the first embodiment described above, the unvulcanized rubber 18 provided between the heat exchange laminate 11 and the corner member 12 is heated to ensure an airtight state.

[0054] In addition, although in the first embodiment, the notch of the joint portion between the corner member 12 and the corner portion of the heat exchange laminate 11 is formed as Picture 10 The shape shown in (a), but not limited to this, can be formed as Picture 10 Various shapes shown in (b) to (f). Furthermore, shapes other than the above-mentioned shapes can also be appropriately adopted.

[0055] The heat exchanger of the present invention is manufactured by the above method, and can be used as a heat exchanger in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com