Grinding machine for aggregate production

A grinding machine and grinding mechanism technology, applied in grain processing, etc., can solve the problems of simultaneous grinding of aggregates, sieving of ground materials, and failure to form, so as to reduce intermediate transfer links, improve production efficiency, and ensure service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

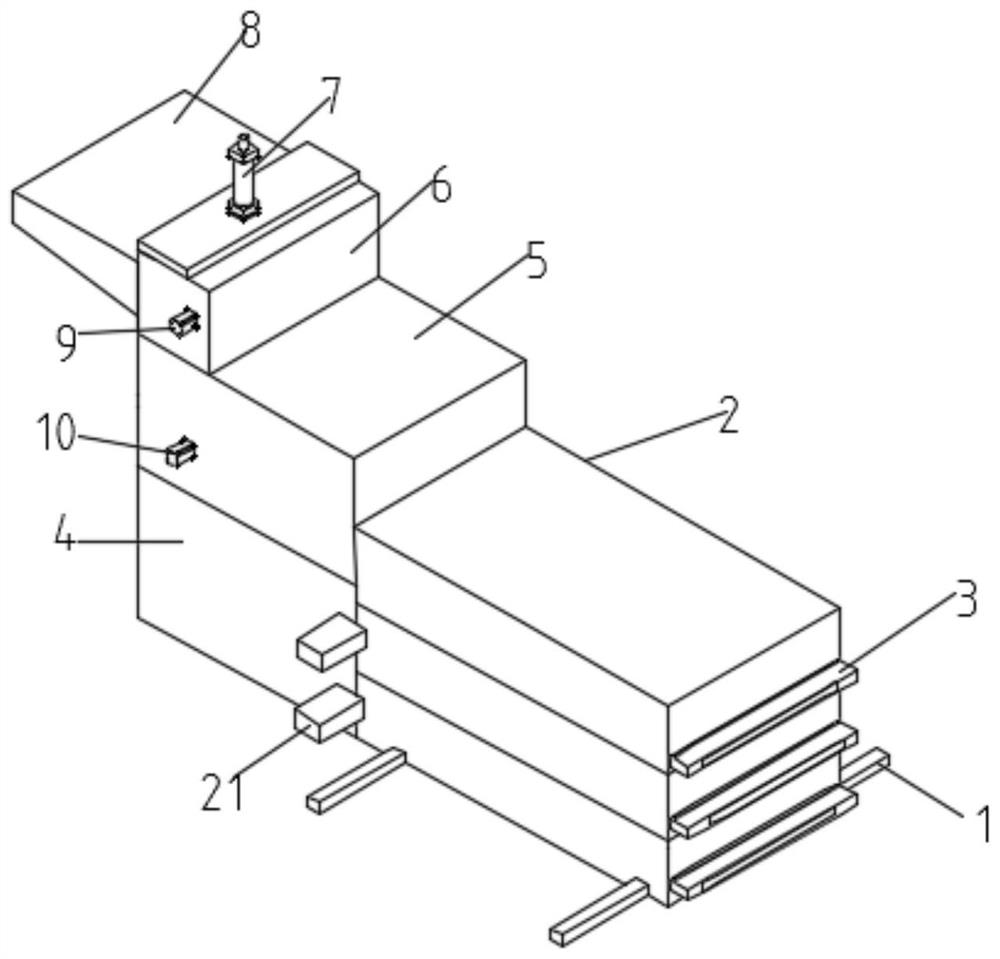

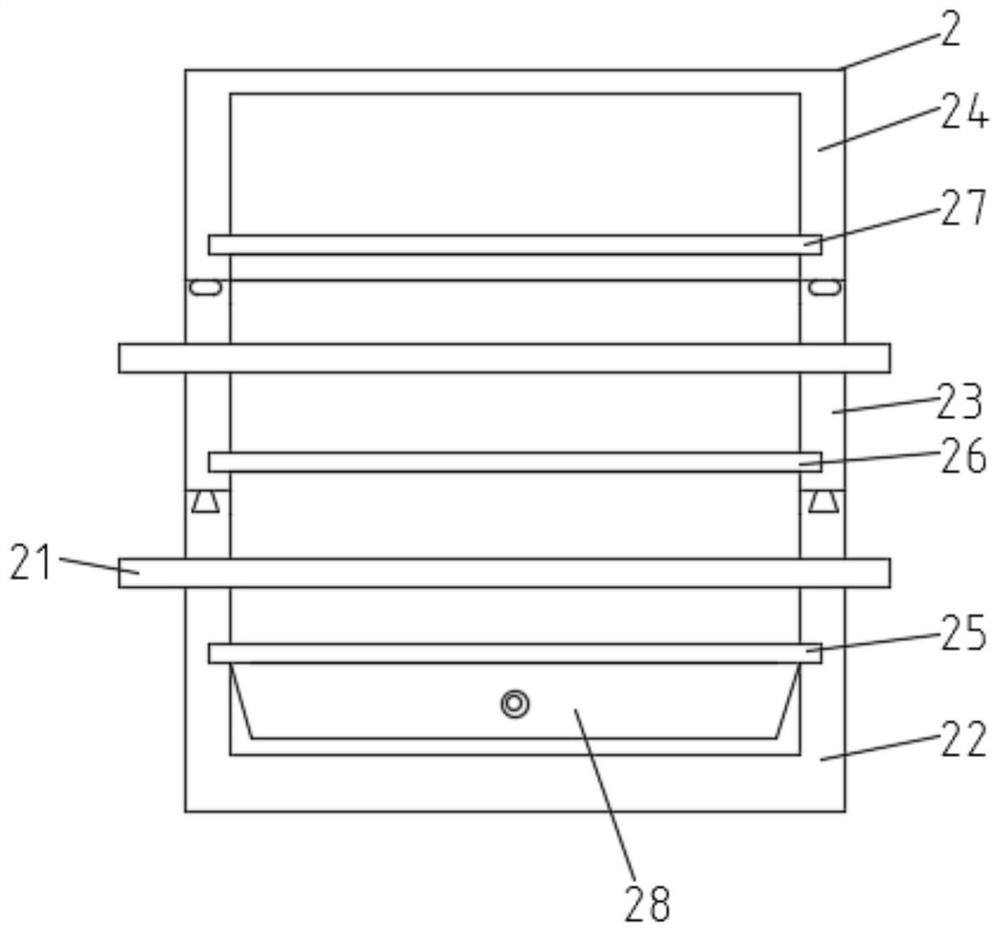

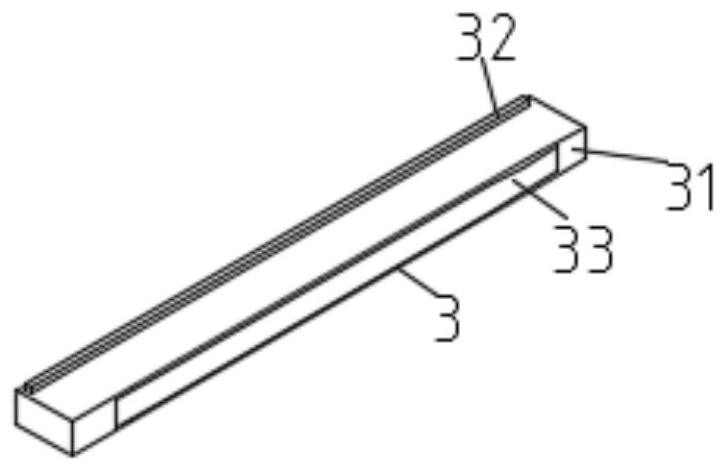

[0029] The present invention is a grinder for aggregate production, which comprises two fixed slide rails 1 arranged side by side and two fixed plates 4 arranged side by side on the fixed slide rails 1, on which the fixed slide rails 1 slide A discharge mechanism 2 is installed, and the rear of the fixed slide rail 1 is provided with a driving member for driving the discharge mechanism 2 to do reciprocating linear motion. One side of the discharge mechanism 2 is slidingly connected with the fixed plate 4, and the upper end of the fixed plate 4 is provided with Grinding box body 5, grinding box body 5 is built-in grinding mechanism, and the front end of grinding box body 5 is provided with the driver part 2 10 that is used to drive grinding mechanism to grind, and the upper end of grinding box body 5 is provided with pre-crushing box body 6, pre-crushing The pre-crushing mechanism is built into the casing 6, and the front end of the pre-crushing casing 6 is provided with a drive...

Embodiment 2

[0034] The difference from the first embodiment is that the specific structures of the first clamping part 61 and the second clamping part 62 are also disclosed. Explanation, the clamping part 1 61 includes the clamping plate 1 611, the two sides of the clamping plate 611 are fixedly installed with the clamping plate 2 612, and the pre-shredding box 6 is provided with a and the second clamping plate 612 is fixed inside the installation groove by bolts, so that the second clamping plate 612 and the outer surface of the pre-crushing box 6 are on the same horizontal plane, wherein the lower end of the first clamping plate 611 is symmetrically opened There is a snap-in groove 613. In specific use, the snap-in slot 613 matches the connecting column 632. The snap-in slot 613 on the snap-in plate 1 611 cooperates with the pre-crushing box 6, so that the connecting post 632 can be smoothly inserted into the snap-in slot. 613, because the diameter of the connecting column 632 is smalle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com