Continuous reaction regeneration system and method for converting C3-C9 hydrocarbon and alcohol ether into aromatic hydrocarbon

A C3-C9, reaction regeneration technology, used in chemical instruments and methods, condensation between hydrocarbons and non-hydrocarbons to produce hydrocarbons, organic chemistry, etc., can solve the problems of high energy consumption, complex process, etc. The effect of prolonging the start-up period, strengthening the gas-solid contact and catalytic conversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

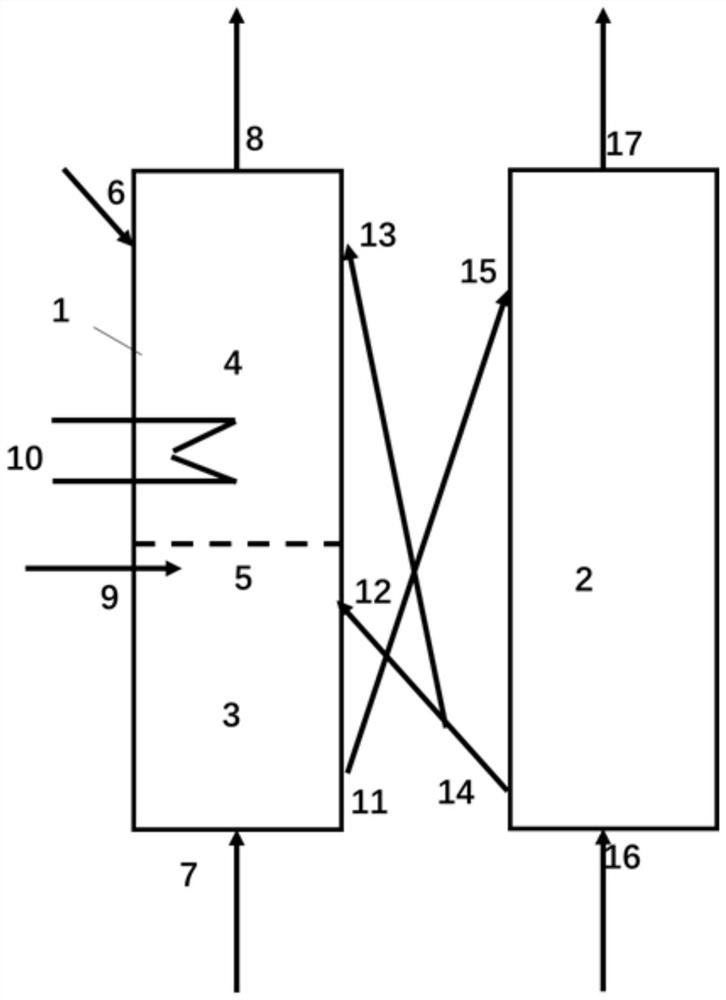

[0041] Will C 3 -C 9 The two-stage fluidized bed (1) for producing aromatics from hydrocarbons and alcohol ethers is connected with the catalyst regeneration fluidized bed (2) with pipelines to form a complete system; the C 3 -C 9 Catalyst for producing aromatics from hydrocarbons and alcohol ethers (2% gallium oxide-3% yttrium oxide-1% cerium oxide-44% β molecular sieve-50% ZSM-5) loaded into C 3 -C 9 In the two-stage fluidized bed (1) for producing aromatics from hydrocarbons and alcohol ethers and the catalyst regeneration fluidized bed (2), first realize the smooth circulation flow of the catalyst in the system;

[0042] Hot air is passed into the catalyst regeneration fluidized bed (2) so that the temperature in the catalyst regeneration fluidized bed (2) reaches 600°C. In an atmosphere that ensures the safety of the system, the catalyst in the catalyst regeneration fluidized bed (2) is circulated to C 3 -C 9 In the two-stage fluidized bed (1) for preparing aromatic...

Embodiment 2

[0049] The two-stage fluidized bed (1) of C3-C9 hydrocarbons and alcohol ether aromatics is connected with the catalyst regeneration fluidized bed (2) with pipelines to form a complete system; the C 3 -C 9 Catalyst for producing aromatics from hydrocarbons and alcohol ethers (3% zinc oxide-0.5% lanthanum oxide-1% chromium oxide-24% ZSM-5-30% Y molecular sieve-41.5% SBA-15) loaded into C 3 -C 9 In the two-stage fluidized bed (1) for producing aromatics from hydrocarbons and alcohol ethers and the catalyst regeneration fluidized bed (2), first realize the smooth circulation flow of the catalyst in the system;

[0050] Pass hot air into the catalyst regeneration fluidized bed (2) to bring the temperature in the catalyst regeneration fluidized bed (2) to 648°C. In an atmosphere that ensures the safety of the system, the catalyst in the catalyst regeneration fluidized bed (2) is circulated to C 3 -C 9 In the two-stage fluidized bed (1) for preparing aromatics from hydrocarbon a...

Embodiment 3

[0057] Will C 3 -C 9 The two-stage fluidized bed (1) for producing aromatics from hydrocarbons and alcohol ethers is connected with the catalyst regeneration fluidized bed (2) with pipelines to form a complete system; the C 3 -C 9 Catalysts for producing aromatics from hydrocarbons and alcohol ethers (1% gallium oxide-25% ZSM-22-40% MCM-41-34% MCM-22) loaded into C 3 -C 9 In the two-stage fluidized bed (1) for producing aromatics from hydrocarbons and alcohol ethers and the catalyst regeneration fluidized bed (2), first realize the smooth circulation flow of the catalyst in the system;

[0058] Pass hot air into the catalyst regeneration fluidized bed (2) to bring the temperature in the catalyst regeneration fluidized bed (2) to 635°C. In an atmosphere that ensures the safety of the system, the catalyst in the catalyst regeneration fluidized bed (2) is circulated to C 3 -C 9 In the two-stage fluidized bed (1) for preparing aromatics from hydrocarbon and alcohol ether, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com