Preparation method and application of bismuth nanoparticle composite material protected by double carbon layers

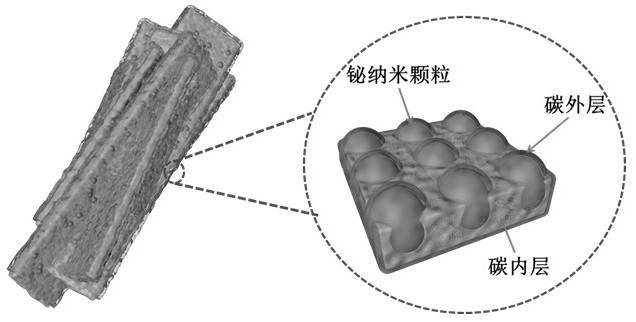

A particle composite, bismuth nanotechnology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of complex preparation method, large cycle loss, uneven size of bismuth nanoparticle, etc. Achieve the effect of alleviating volume changes, maintaining integrity, and ensuring cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Step 1: Disperse 150 mg of bismuth nitrate pentahydrate and 750 mg of organic ligand trimesic acid in 60 mL of a mixed solvent of methanol and DMF (volume ratio of methanol to DMF: 1:4), and stir for 30 minutes to form a transparent and uniform solution.

[0047] Step 2: Place the transparent and uniform solution in step 1 in a 100mL hydrothermal reaction kettle, conduct hydrothermal reaction at 180°C for 12h, and filter and dry to obtain the Bi MOF precursor.

[0048] Step 3: Take 400 mg of the dried Bi MOF precursor in step 2 and ultrasonically disperse it in 200 mL of Tris buffer solution (10 mM, pH = 8-9) for 0.5 h. Under vigorous stirring, 200 mg of dopamine hydrochloride solution was added to the solution, and the stirring was continued for 12 h to obtain Bi MOF@PDA.

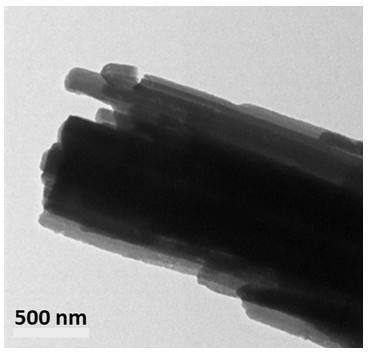

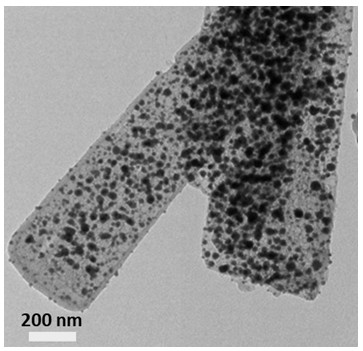

[0049] Step 4: The 50mg BiMOF@PDA product obtained in Step 3 is filtered, washed and dried, and placed in two quartz boats with 500mg of dicyandiamide, and then placed in a tube furnace for heat tre...

Embodiment 2

[0056] With embodiment 1, difference is:

[0057] Step 4: The 300mg BiMOF@PDA product obtained in Step 3 was filtered, washed and dried, and placed in two quartz boats with 300mg of dicyandiamide, and then placed in a tube furnace for heat treatment, equipped with dicyandiamide The amine quartz boat was placed above the air flow, and the temperature was raised from room temperature to 800°C at a rate of 2°C / min in an argon atmosphere, and kept for 3 hours for full calcination to obtain the calcined product Bi / C.

[0058] Embodiment 2 has selected different precursor dosage ratios, and its transmission electron microscope photograph of gained Bi / C composite material is as follows Figure 6 shown.

Embodiment 3

[0060] With embodiment 1, difference is:

[0061] Step 4: The 50mg BiMOF@PDA product obtained in Step 3 is filtered, washed and dried, and placed in two quartz boats with 500mg of dicyandiamide, and then placed in a tube furnace for heat treatment, equipped with dicyandiamide The amine quartz boat was placed above the gas flow, and the temperature was raised from room temperature to 1000°C at a rate of 2°C / min in an argon atmosphere, and kept for 3 hours for full calcination to obtain the calcined product Bi / C.

[0062] Embodiment 3 selects the calcining temperature different from embodiment 1, under higher carbonization temperature, Ostwald phenomenon has occurred, and its transmission electron micrograph is as follows Figure 7 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com