Negative plate and lithium ion battery comprising same

A lithium-ion battery and negative electrode technology, which is applied in the direction of negative electrodes, battery electrodes, secondary batteries, etc., can solve the problems of poor charging and discharging effects at large rates and high discharge specific capacity, and achieve rapid transmission and isotropic Good, the effect of improving power performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] Preparation of the negative electrode sheet: at 25°C, the negative electrode material prepared in the following examples and comparative examples was mixed with carboxymethyl cellulose (CMC), conductive carbon black, and styrene-butadiene rubber (SBR) in a mass ratio of 92% : 1.5% : 1.5% : 5% were mixed evenly in pure water to prepare negative electrode slurry 1; evenly coated negative electrode slurry 1 on 8μm copper foil, the coating surface density was about 8mg / cm 2 , and then put the copper foil in a vacuum drying oven at 80°C for 12 hours. Cut the dried pole piece into a disc with a diameter of 20mm to make a working electrode.

[0042] (2) Assembly of the half-cell: at room temperature, with the metal lithium sheet as the counter electrode, the above-mentioned working electrode, the polyethylene diaphragm as the battery diaphragm, and 1mol / L LiPF 6 / EC:DEC (volume ratio is 1:1) solution is the electrolyte, and it is assembled into a CR2430 button battery in a gl...

Embodiment 1

[0053] (1) Preparation of negative electrode active material: Spherical graphite raw material is obtained after flake graphite is pulverized, shaped and spheroidized, and the raw material is subjected to mechanical treatment, asphalt coating modification, carbonization heat treatment and sieving and demagnetization to obtain natural graphite negative electrode active material .

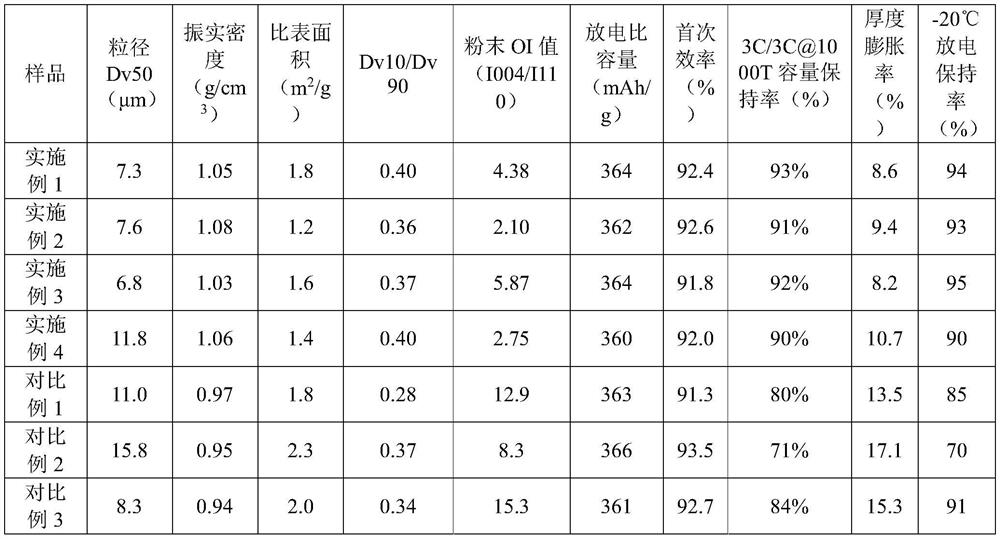

[0054] According to the test, the particle size distribution of the negative active material is: Dv50=7.3μm, Dv10=4.2μm, Dv90=10.5μm; the tap density is 1.05g / cm 3 ;The specific surface area is 1.8m 2 / g; the discharge specific capacity of the half-cell is 364mAh / g, and the initial efficiency is 92.4%; the OI value of the powder, I004 / I110 is 4.38.

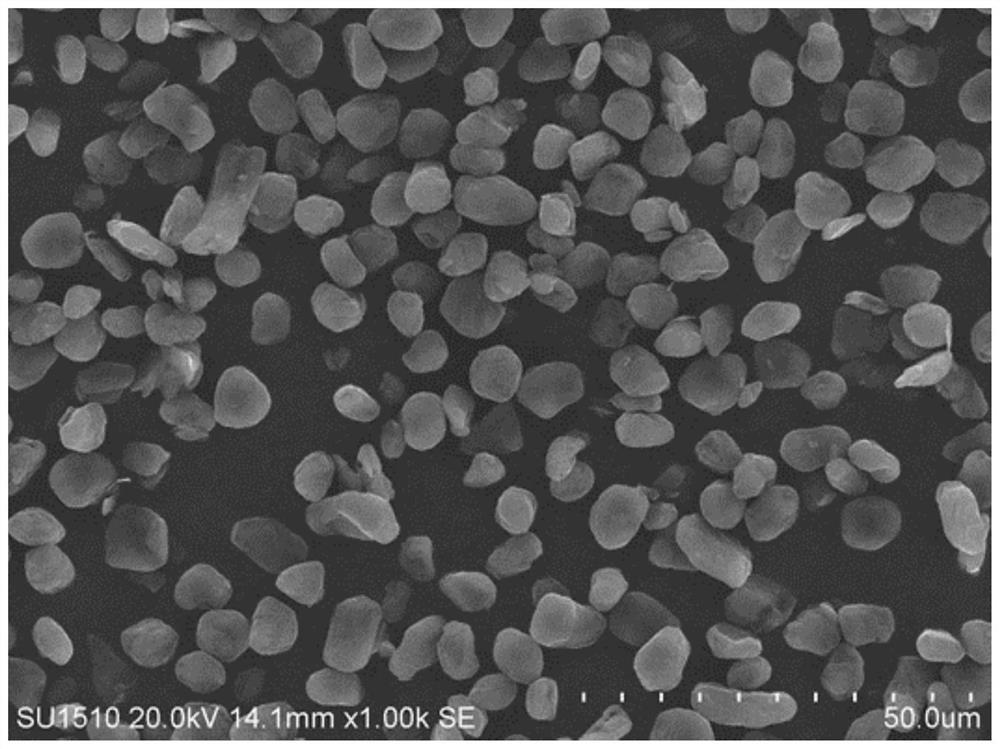

[0055] figure 1 is the SEM figure of the negative electrode active material in embodiment 1, by figure 1 It can be seen from the figure that the particle size of the natural graphite negative electrode active material is small, its particle size distri...

Embodiment 2

[0060] (1) Preparation of the negative electrode active material: refer to the preparation method of the negative electrode active material in Example 1 to obtain the natural graphite negative electrode active material.

[0061] It can be seen from the test that the particle size distribution of the negative electrode active material is: Dv50=7.6 μm, Dv10=4.0 μm, Dv90=11.0 μm; the tap density is 1.08 g / cm 3 ;The specific surface area is 1.2m 2 / g; the discharge specific capacity of the half-cell is 362mAh / g, and the initial efficiency is 92.6%; the powder OI value I004 / I110 is 2.10.

[0062] (2) The preparation of the negative electrode sheet and the full battery is the same as in Example 1, and a soft pack battery 2 is obtained.

[0063] The test results of pouch battery 2 are: at 25°C 3C / 3C cycle for 1000 cycles, the capacity retention rate is 91%, the battery thickness expansion rate is 9.4%, and the -20°C discharge capacity retention rate is 93%, see Table 1 for details ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com