Process for recovering waste liner of aluminium electrolyzer

An aluminum electrolytic cell and recycling method technology, applied in the direction of solid waste removal, waste treatment, etc., can solve the problems of small recycling volume, non-recycling, and high requirements for equipment technical conditions, and achieve the effect of large recycling volume and easy application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

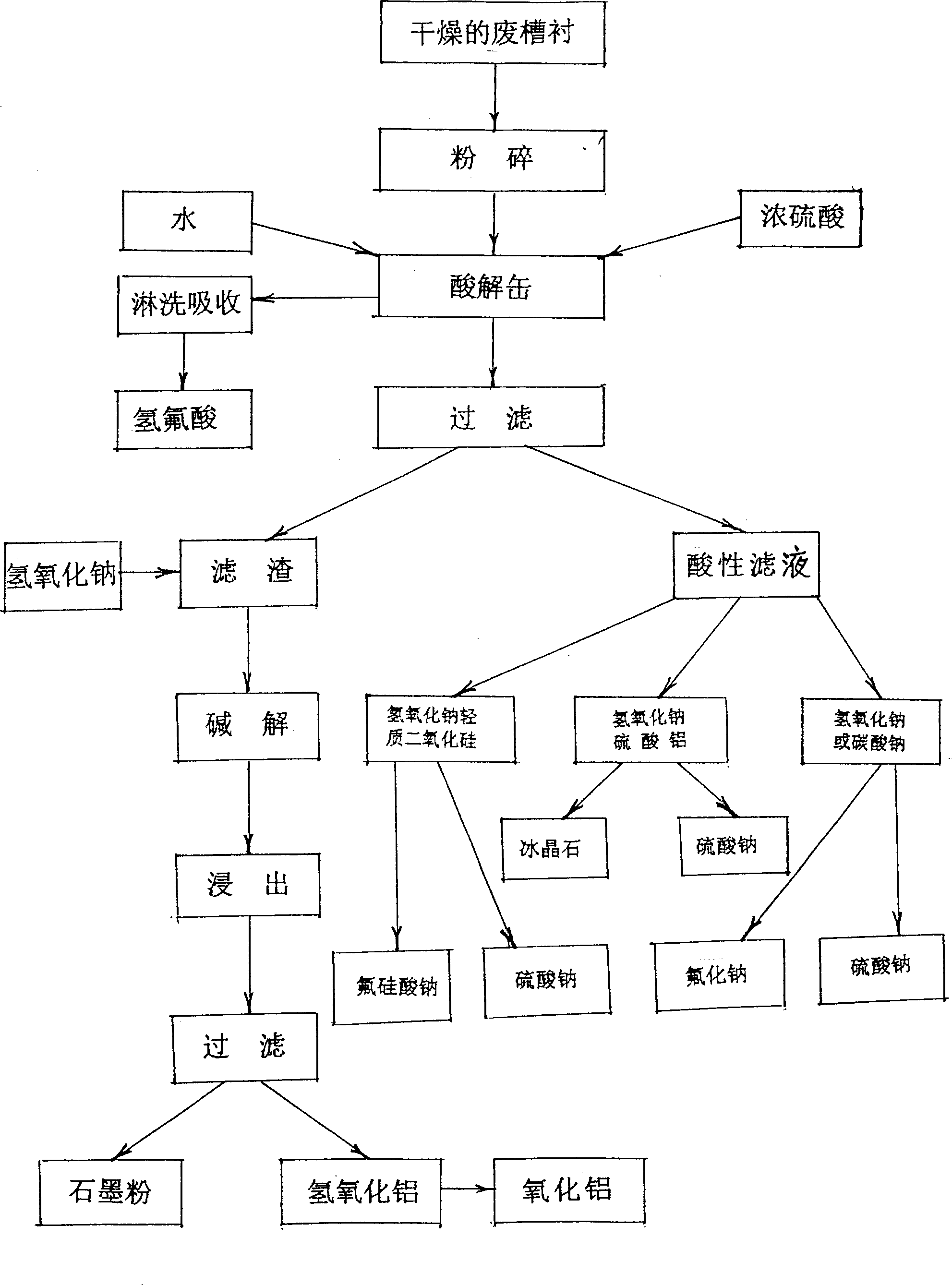

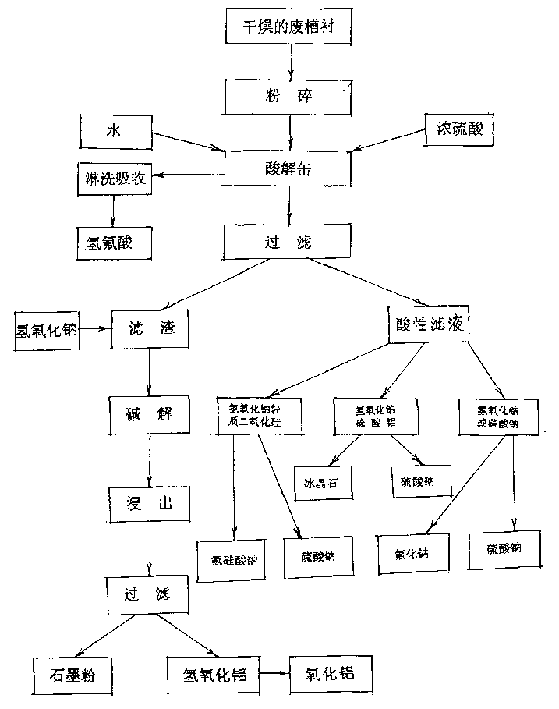

Image

Examples

Embodiment 1

[0016] Embodiment 1: Recycling dilute industrial hydrofluoric acid, producing filter residue raw materials for producing graphite powder, aluminum hydroxide, and aluminum oxide, and acid solution raw materials for producing various fluoride salts and sulfate products. Its specific steps are:

[0017] 1. Crushing and processing the dried waste lining of the aluminum electrolytic cell into -100 mesh powder for later use.

[0018] 2. Inject 90 kg of water into the acid hydrolysis tank with heat preservation facilities, and then add 310 kg of industrial concentrated sulfuric acid with a concentration of 98%. In the solution tank, start the agitator to stir evenly, and the substances in the acid solution tank undergo a chemical reaction.

[0019] 3. The gas produced by the reaction in the acidolysis tank is introduced into the rinsing absorption tower for repeated rinsing and absorption with water, and the discharged liquid is dilute industrial hydrofluoric acid.

[0020] 4. When...

Embodiment 2

[0021] Embodiment two: produce industrial sodium fluorosilicate and industrial sodium sulfate.

[0022] Combine the acidic filtrate in Example 1 and the acid water discharged from the rinsing filter residue, pour it into a neutralization tank, add 5 kg of burnt rice husk ash, then add 46 kg of light silica, stir slowly for 30 minutes, add 116 kilograms of sodium hydroxide (or add 154 kilograms of sodium carbonate) continue to stir for 20 minutes, after standing still for 30 minutes, remove the remaining rice husk ash on the surface of the liquid in the tank, and filter, and the filtrate is concentrated and crystallized, and industrial sodium sulfate 200 is recovered. kg, the filter residue is washed with water until PH = 6 and then dried, and 90 kg of industrial sodium fluorosilicate can be obtained.

Embodiment 3

[0023] Embodiment three: produce cryolite and industrial sodium sulfate.

[0024] The acidic filtrate in Example 1 and the acid hydration discharged by washing the filter residue are combined and injected into the neutralization tank, and after adding 210 kilograms of sodium hydroxide (or 252 kilograms of sodium carbonate) to stir and completely dissolve, then add 70 kilograms of anhydrous aluminum sulfate powder After stirring for 30 minutes, filter, rinse the filter residue with water until pH ≥ 5, then dry the filter residue to produce 110 kg of industrial sodium fluoroaluminate (ie cryolite). The filtrate was concentrated and crystallized, and 250 kg of industrial sodium sulfate was recovered.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com