Electro-hydraulic servo synchronous lifting mechanism

A synchronous lifting, electro-hydraulic servo technology, applied in servo motors, lifting devices, servo motor components, etc., can solve problems such as stuck, insufficient lifting, and large vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

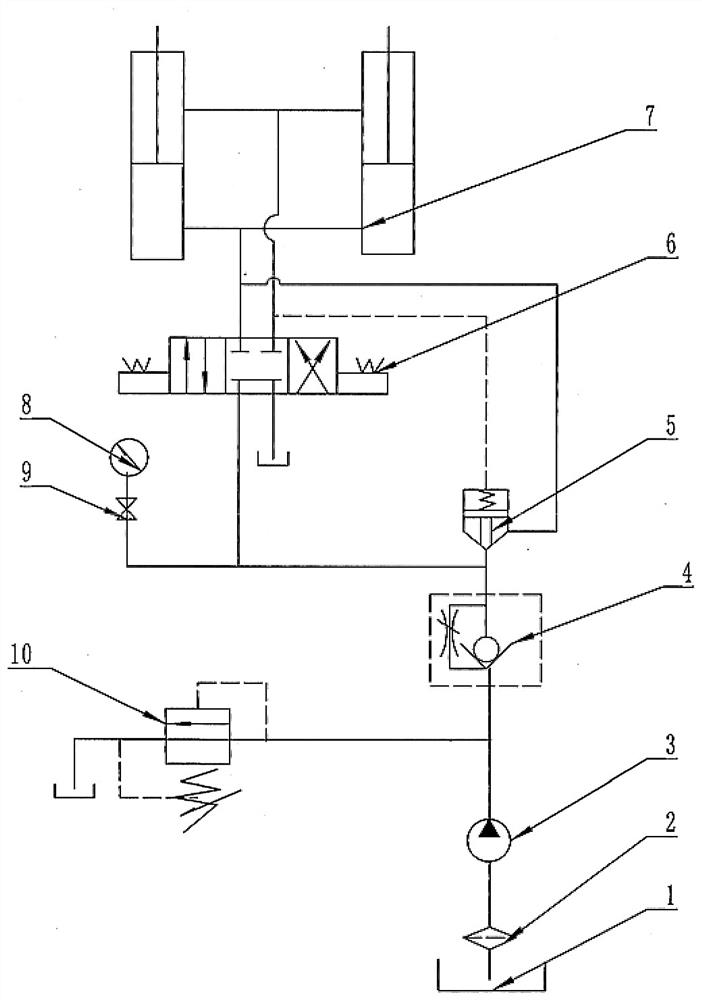

[0006] The preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings. The electro-hydraulic servo synchronous lifting mechanism consists of: fuel tank 1, oil filter 2, oil pump 3, one-way throttle valve 4, cartridge valve 5, electro-hydraulic synchronous valve 6 , Lift cylinder 7, pressure gauge 8, stop valve 9, pressure relief valve 10 constitute. Oil tank 1 is connected with oil filter 2, oil filter 2 is connected with oil pump 3, oil pump 3 is connected with one-way throttle valve 4 and pressure relief valve 10 respectively, one-way throttle valve 4 is connected with stop valve 9, pressure The gauge 8 is connected to the cartridge valve 5, the cartridge valve 5 is connected to the electro-hydraulic synchronous valve 6 and the lifting cylinder 7, and the lifting cylinder 7 is connected to the electro-hydraulic synchronous valve 6.

[0007] Working principle, when the hydraulic system is working, the oil pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com