Autoclaved aerated concrete slab

A concrete slab and autoclaved aerated technology, which is applied to building components, building insulation materials, thermal insulation, etc., can solve the problems of single autoclaved aerated concrete slab structure, lack of firmness, poor seismic effect, etc., and achieve improved Antifreeze effect, good pouring compactness, good high temperature resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] see Figure 1-2 , the present invention provides an autoclaved aerated concrete slab technical solution: an autoclaved aerated concrete slab, comprising a concrete slab 1, the concrete slab 1 is composed of an upper waterproof layer 101, an upper heat insulation layer 102, a sound insulation layer 103, a lower heat insulation layer 104 and The lower waterproof layer 105 is combined, the lower side of the upper waterproof layer 101 is poured with an upper heat insulation layer 102, the lower side of the upper heat insulation layer 102 is poured with a sound insulation layer 103, and the lower side of the sound insulation layer 103 is poured with a lower heat insulation layer 104 , the lower side of the lower heat insulation layer 104 is poured with a lower waterproof layer 105, which is formed by combining the concrete slab 1 with an upper waterproof layer 101, an upper heat insulation layer 102, a sound insulation layer 103, a lower heat insulation layer 104, and a lower...

Embodiment 2

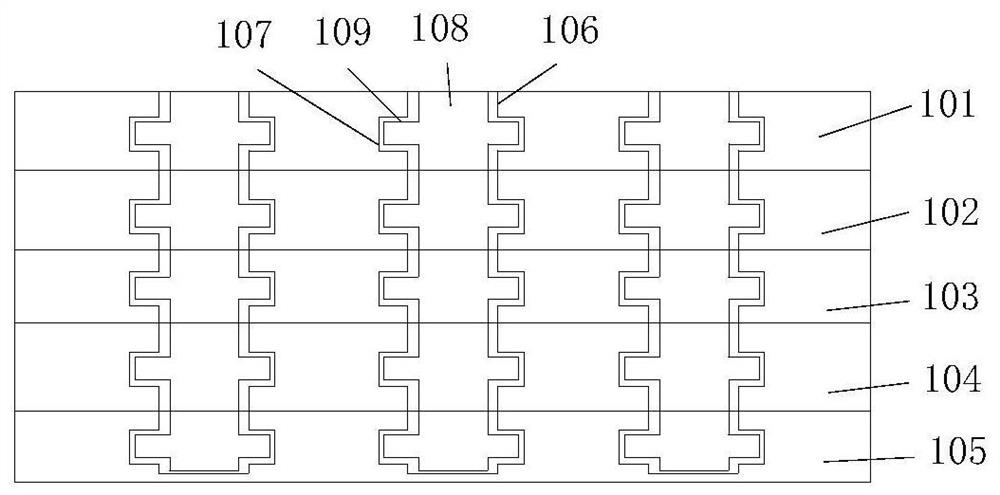

[0034] see Figure 1-3On the basis of Embodiment 1, the upper side of the upper waterproof layer 101 is provided with a through groove 106 that penetrates the interior of the upper waterproof layer 101 and the upper heat insulation layer 102, the sound insulation layer 103, the lower heat insulation layer 104 and the lower waterproof layer 105. , the interior of the upper waterproof layer 101 is provided with an inner groove 107 communicating with the through groove 106, and the interior of the upper heat insulation layer 102, the sound insulation layer 103, the lower heat insulation layer 104 and the lower waterproof layer 105 is also provided with an inner groove 107. The inside of the groove 106 is poured with a through column 108, and the inside of the inner groove 107 is poured with a fixed column 109 with the same material as the through column 108. By utilizing the through groove 106 that is opened up and down in the interior of the concrete slab 1, the through column 10...

Embodiment 3

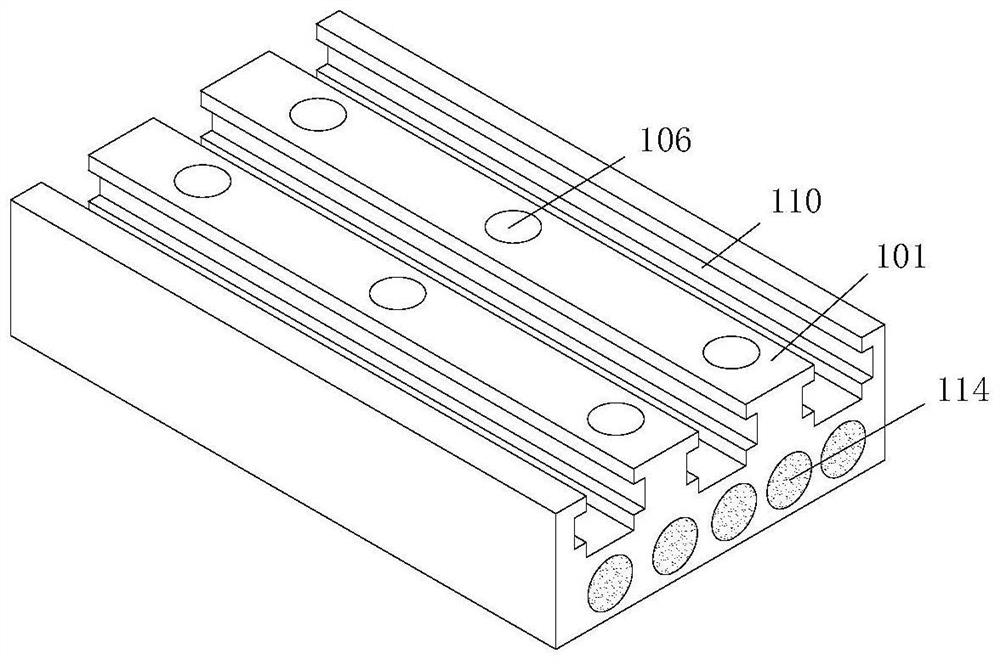

[0037] see Figure 4-5 On the basis of Embodiment 1, an upper groove 110 is provided on the upper side of the upper waterproof layer 101, and the left and right sides of the upper waterproof layer 101, the upper heat insulation layer 102, the sound insulation layer 103, the lower heat insulation layer 104 and the lower waterproof layer 105 The side is fixedly connected with the second rectangular plate 112 and the first rectangular plate 111, and the inner wall of the upper tank 110 is poured with an upper column 113 fixedly connected with the first rectangular plate 111 and the second rectangular plate 112, through the upper waterproof layer 101, the upper The first rectangular plate 111 and the second rectangular plate 112 of a rectangular surface are poured on both sides of the heat insulation layer 102, the sound insulation layer 103, the lower heat insulation layer 104 and the lower waterproof layer 105, which ensures the upper waterproof layer 101 and the upper heat insul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com