Preparation method of flame-retardant non-woven fabric and product thereof

A flame retardant non-woven and non-woven technology, which is applied in the manufacture of fire-retardant and flame-retardant filaments, textiles and paper, non-woven fabrics, etc., can solve problems such as serious hazards, large amounts of gas and smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

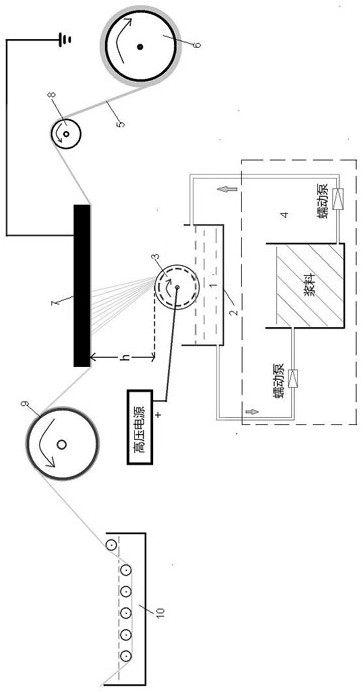

Image

Examples

Embodiment 1

[0024] A kind of flame-retardant non-woven fabric, is prepared according to the following steps:

[0025] Preparation of flame retardant solution of graphene:

[0026] (1) Take 5g of graphene, 1g of propyltriethoxysilane isocyanate, 0.1g of n-butyltin dilaurate, and 900g of tetrahydrofuran and pour them into the wet grinding equipment in sequence. The grinding medium is zirconia with a diameter of ≤0.1mm The microspheres are pre-mixed and poured into the wet grinding equipment. The grinding medium is zirconia microspheres, and the grinding speed is 2000rpm. During the grinding, the temperature of the material is controlled below 3°C, and the material is discharged after 2 hours of grinding. After 100 g of ionized water, reflux and stir under nitrogen protection for 12 hours, and the reflux reaction temperature is 60 ° C to obtain a graphene solution;

[0027] (2) Take 50g of phosphorus-containing organosilicon DOPO-VTS, DOPO-VTS is the compound of 9,10-dihydro-9-oxa-10-phosph...

Embodiment 2

[0036] A kind of flame-retardant non-woven fabric, similar to embodiment 1 step, is prepared according to the following steps:

[0037] Preparation of flame retardant solution of graphene:

[0038] (1) Take 7.5g of graphene, 1.5g of propyltriethoxysilane isocyanate, 0.15g of n-butyltin dilaurate, and 1350g of tetrahydrofuran and pour them into the wet grinding equipment in sequence. The grinding medium is zirconia microspheres. After premixing, it is poured into the wet grinding equipment. The grinding medium is zirconia microspheres, and the grinding speed is 2000rpm. During the grinding, the temperature of the material is controlled below 3°C. After grinding for 2 hours, the material is discharged, and then 18g of hydrochloric acid and 150g of deionized water are added. Under nitrogen protection, reflux and stir for 12 hours, and the reflux reaction temperature is 60°C to obtain a graphene solution;

[0039] (2) Dissolve 50 g of phosphorus-containing silicone DOPO-VTS in 45...

Embodiment 3

[0044] A kind of flame-retardant non-woven fabric, similar to embodiment 1 step, is prepared according to the following steps:

[0045] Preparation of flame retardant solution of graphene:

[0046] (1) Take 10g of graphene, 2g of propyl isocyanate triethoxysilane, 0.2g of n-butyltin dilaurate, and 1800g of tetrahydrofuran and pour them into the wet grinding equipment in sequence. The grinding medium is zirconia microspheres. After mixing, pour it into the wet grinding equipment. The grinding medium is zirconia microspheres. The grinding speed is 2000rpm. During the grinding, the temperature of the material is controlled below 3°C. After 2 hours of grinding, the material is discharged. Under protection, reflux and stir for 12 hours, and the reflux reaction temperature is 60°C to obtain a graphene solution;

[0047] (2) Dissolve 50 g of phosphorus-containing silicone DOPO-VTS in 450 g of tetrahydrofuran and add it to the graphene solution in (1), then add 10 g of ammonia water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com