Electrospinning nano-fiber electret filtering material and its preparation method

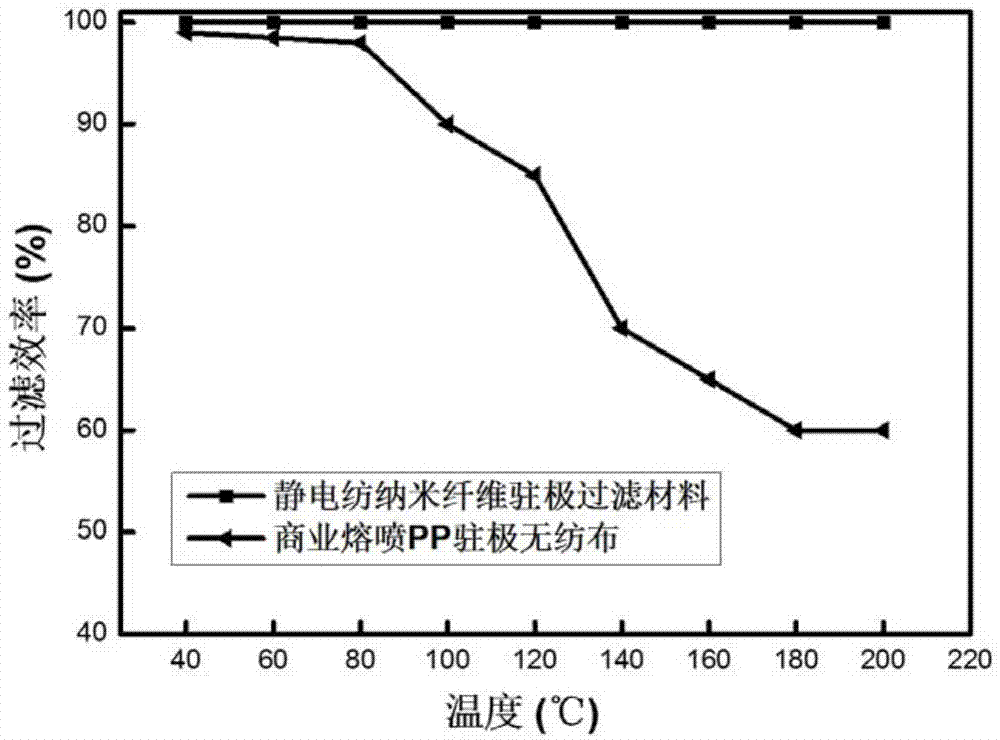

A nanofiber and filter material technology, applied in the field of electrospinning nanofiber electret filter material and its preparation, can solve the problems of space charge dissipation, charge performance attenuation, and electret performance failing to meet actual use requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

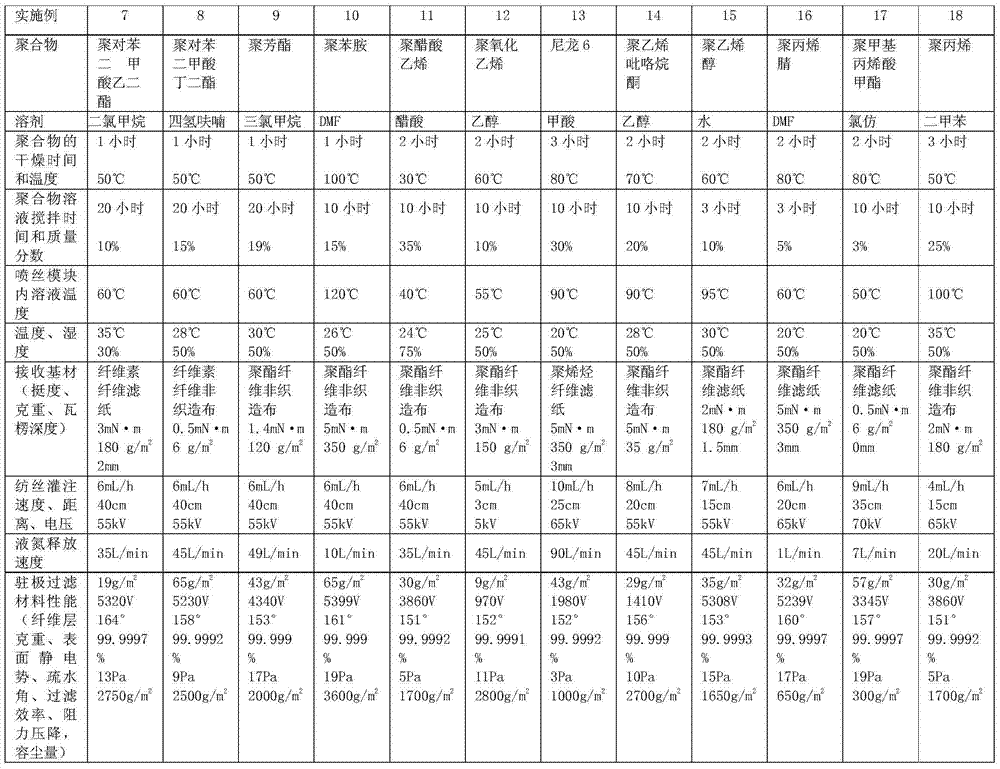

Examples

Embodiment 1

[0067] An electrospun nanofiber electret filter material and a preparation method thereof, the specific steps are:

[0068] The first step: Put the polyvinylidene fluoride powder in a vacuum oven at 80° C. and dry it under vacuum for 3 hours.

[0069] The second step: dissolve the dried polyvinylidene fluoride powder in N,N-dimethylformamide, and place the solution on a magnetic stirrer and stir for 10 hours to form a homogeneous solution; The mass fraction of polyvinylidene fluoride in the solution is 40%.

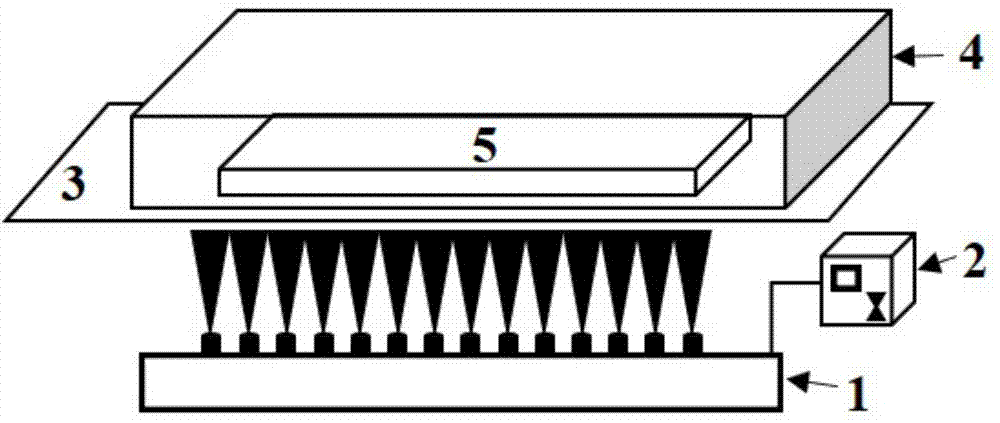

[0070] Step 3: Use figure 1 In the electrospinning equipment shown for spinning, a certain amount of the above-mentioned polyvinylidene fluoride polymer solution is drawn into the spinneret module 1, and the temperature control device 2 of the spinneret module is adjusted to 70°C for 20 minutes to make polymerization The object is evenly heated, and the distance from the spinneret of the spinneret to the receiving substrate is 15cm, and the applied voltage is 60kV.

[0071] Step...

Embodiment 2

[0073] An electrospun nanofiber electret filter material and a preparation method thereof, the specific steps are:

[0074] The first step: Place the polybutylene terephthalate particles in a vacuum oven at 50°C for vacuum drying for 1 hour.

[0075] Step 2: Add boehmite to a certain amount of dichloromethane, and sonicate for 4 hours, then add the dried polybutylene terephthalate particles into the dichloromethane solvent containing boehmite, and add the above solution Place it on a magnetic stirrer and stir for 12 hours to form a homogeneous solution; in the homogeneous solution, the mass fraction of polybutylene terephthalate is 20%, and the boehmite content is the total of polymer and inorganic nanoparticles. The amount is 3wt%.

[0076] Step 3: Use figure 1 In the electrospinning equipment shown in the spinning, a certain amount of the above-mentioned boehmite-containing polybutylene terephthalate polymer solution is pumped into the spinneret module 1 in the 10mL spinneret modu...

Embodiment 3

[0079] An electrospun nanofiber electret filter material and a preparation method thereof, the specific steps are:

[0080] The first step: the fluorinated polyurethane particles and polyethersulfone particles are placed in a vacuum oven at 70°C and 80°C, respectively, and dried under vacuum for 2 hours. Step 2: Add silsesquioxane to a certain amount of formic acid and DMF mixed solvent, and sonicate for 5 hours, then add the dried fluorinated polyurethane particles and polyethersulfone particles to silsesquioxane-containing formic acid and DMF In the mixed solvent, place the above solution on a magnetic stirrer and stir for 10 hours to form a homogeneous solution; in the homogeneous solution, the mass fraction of fluorinated polyurethane and polyethersulfone is 20%, and the mixing ratio of the two is 1:4, the content of silsesquioxane is 3wt% of the total amount of polymer and inorganic nanoparticles.

[0081] Step 3: Use figure 1 In the electrospinning equipment shown in spinnin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stiffness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com