High-entropy perovskite oxide thin film material and preparation method thereof

A technology of perovskite oxide and thin film materials, applied in chemical instruments and methods, magnetic materials, polycrystalline material growth and other directions, can solve the problems of limited modification effect, excessive doping ratio, deterioration of material properties, etc. Effects of novel physical features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

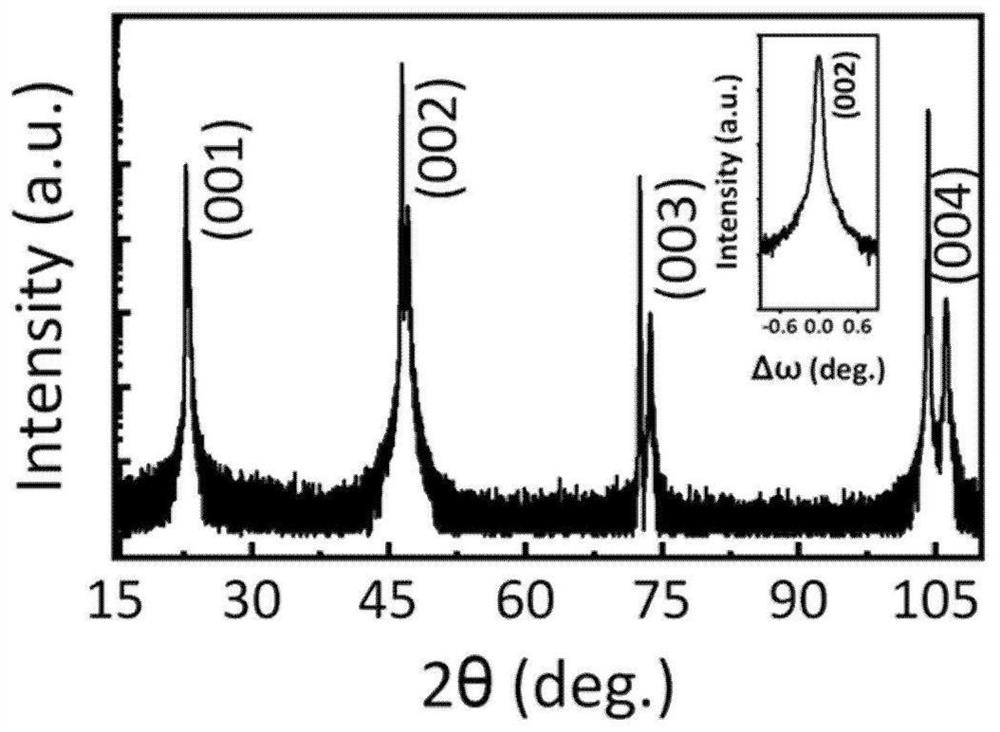

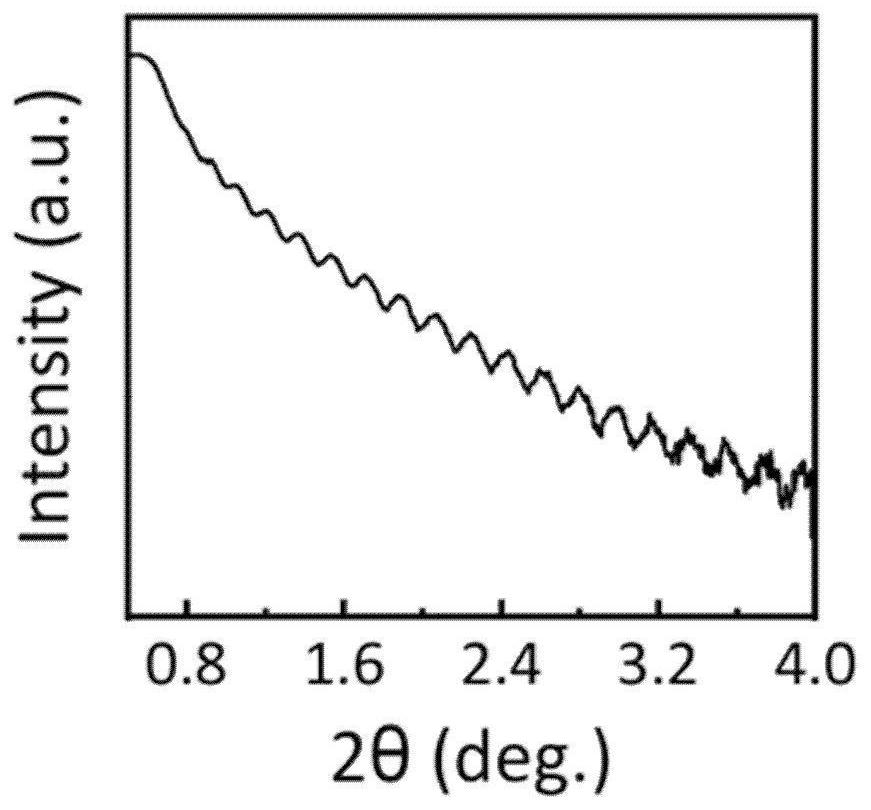

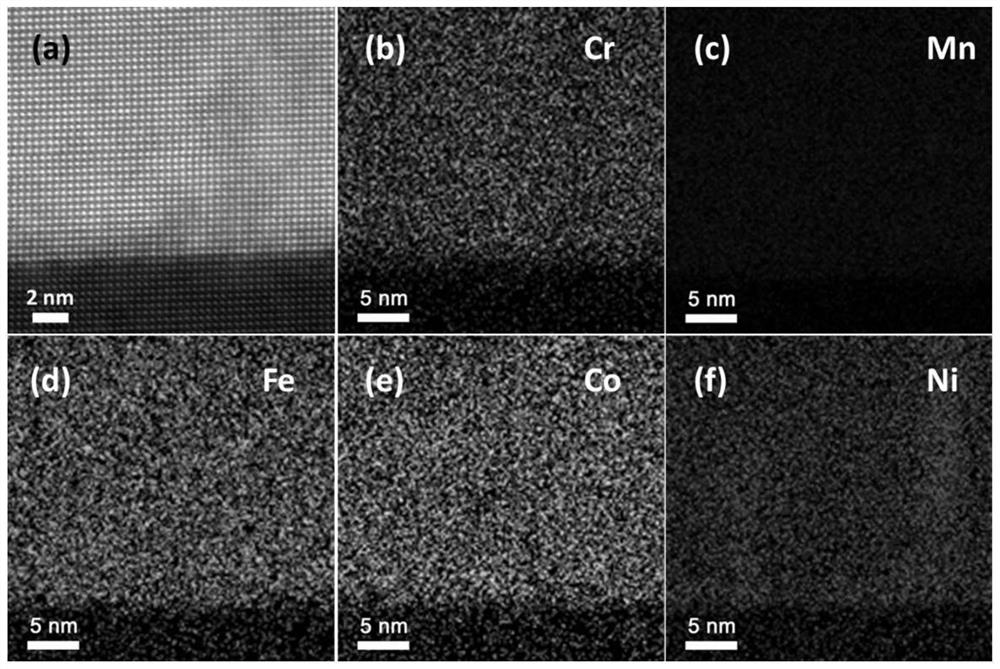

Embodiment 1

[0031] The preparation method of the present embodiment is as follows:

[0032] 1) La with a purity of 99.9% 2 o 3 , NiO, MnO 2 , Fe 2 o 3 、Co 3 o 4 and Cr 2 o 3 The powder is mixed at a molar ratio of 15:6:6:3:2:3 and then sintered to obtain La(Cr 0.2 mn 0.2 Fe 0.2 co 0.2 Ni 0.2 )O 3 target.

[0033] 2) La(Cr 0.2 mn 0.2 Fe 0.2 co 0.2 Ni 0.2 )O 3 The target is placed at the target position in the PLD system, and the SrTiO 3 The substrate is placed in the position of the substrate in the system;

[0034] 3) Vacuum the PLD chamber to 1×10^ -4 Pa, and the substrate temperature was raised to 625°C, and the dynamic oxygen pressure was adjusted to 100mTorr.

[0035] 4) Turn on the laser and set the laser energy to 0.82J / cm 2 , the pulse frequency is 5Hz, and the number of pulses is 3100.

[0036] 5) Open the laser baffle and heater baffle to prepare La(Cr 0.2 mn 0.2 Fe 0.2 co 0.2 Ni 0.2 )O 3 High-entropy perovskite oxide films.

[0037] 6) Cool to roo...

Embodiment 2

[0043] This example is used to illustrate the antiferromagnetic La(Cr 0.2 mn 0.2 Fe 0.2 co 0.2 Ni 0.2 )O 3 High-entropy perovskite oxide films with La 0.67 Sr 0.33 MnO 3 The heterojunction formed by the substrate has obvious exchange bias effect.

[0044] According to the method of embodiment 1, the difference is: in SrTiO 3 La 0.67 Sr 0.33 MnO 3 film, followed by La 0.67 Sr 0.33 MnO 3 La(Cr 0.2 mn 0.2 Fe 0.2 co 0.2 Ni 0.2 )O 3 High-entropy perovskite oxide thin films to obtain La 0.67 Sr 0.33 MnO 3 / La(Cr 0.2 mn 0.2 Fe 0.2 co 0.2 Ni 0.2 )O 3 heterojunction.

[0045] The La(Cr prepared in this embodiment 0.2 mn 0.2 Fe 0.2 co 0.2 Ni 0.2 )O 3 with La 0.67 Sr 0.33 MnO 3 The heterojunction exhibits a pronounced exchange bias effect. From Figure 5 Part (c) shows that after cooling to 10K with a 3T magnetic field, La(Cr 0.2 mn 0.2 Fe 0.2 co 0.2 Ni 0.2 )O 3 with La 0.67 Sr 0.33 MnO 3 In addition to the exchange bias effect in the same...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com