Preparation method of carbon material loaded high-entropy alloy oxygen reduction electrocatalyst

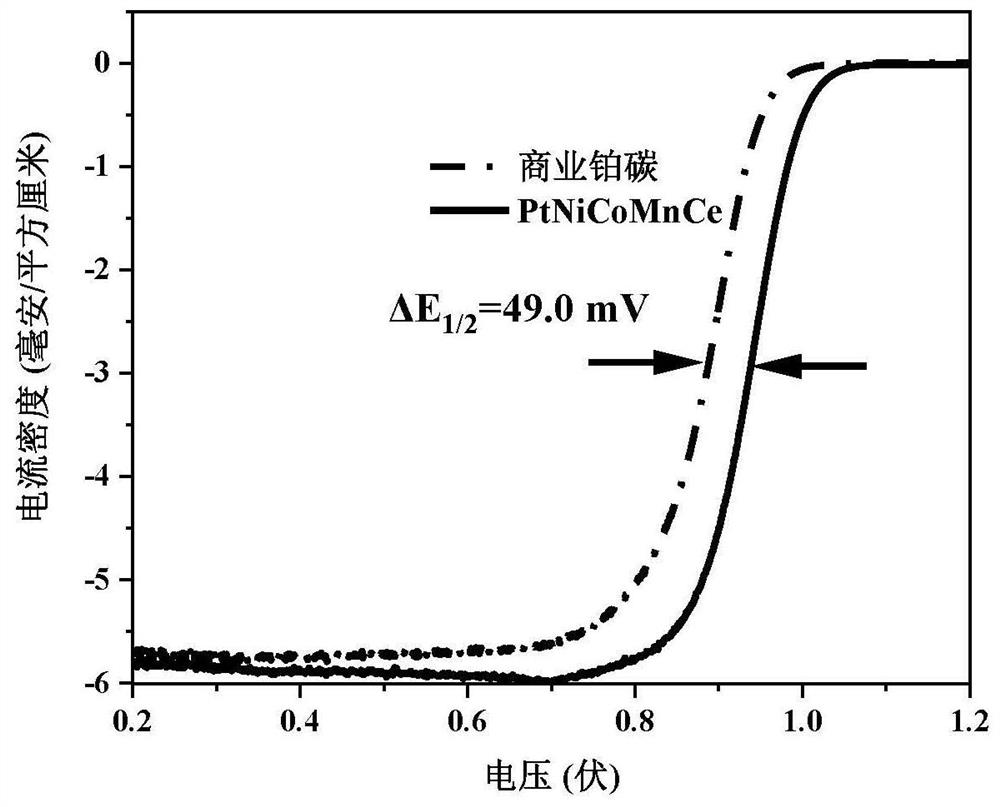

A technology of electrocatalysts and high-entropy alloys, applied in circuits, electrical components, battery electrodes, etc., can solve the problems that the calcination time is not conducive to the large-scale preparation of electrocatalysts, weak oxygen reduction performance, etc., to achieve thermal migration inhibition, good dispersion, Universal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

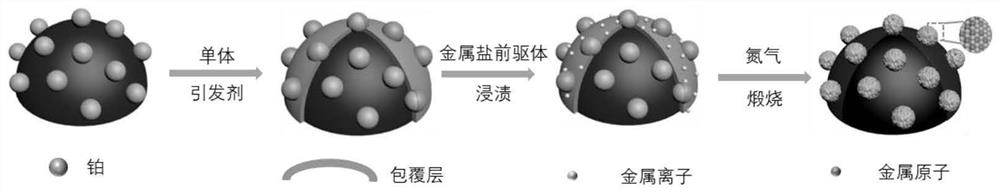

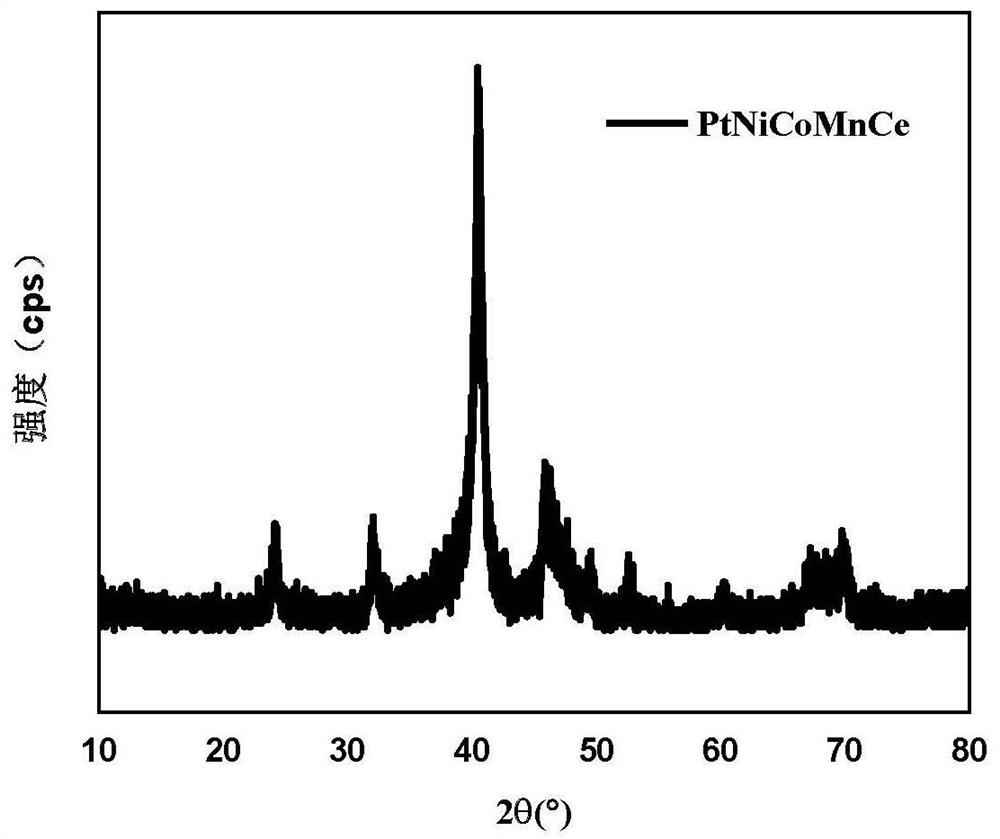

[0023] A method for preparing a carbon material-supported multi-element alloy oxygen reduction electrocatalyst, comprising the following steps:

[0024] (1) in 60ml 0.5M H 2 SO 4 Add 80 mg of commercial platinum carbon and 78.43 μl of aniline monomer to the solution, mix ultrasonically for 30 minutes and then stir at room temperature for 2 hours. Under ice bath conditions, 164.48 mg of ammonium persulfate is used as an initiator to in-situ polymerize aniline on the surface of commercial platinum carbon ; Washing and drying are then carried out to obtain commercial platinum carbon coated with polyaniline on the surface;

[0025] (2) Add 50 ml of commercial platinum carbon coated with polyaniline to an ethanol solution containing nickel acetylacetonate, cobalt acetylacetonate, manganese acetylacetonate and cerium acetylacetonate in equimolar ratio, ultrasonically mix for 30 minutes and then stir at room temperature for 2 hours, Drying by rotary evaporator to obtain commercial ...

Embodiment 2

[0033] On the basis of Example 1, different from Example 1, in step (1): add 40 mg of commercial platinum carbon and 120 mg of dopamine hydrochloride in 40 ml of oxygen-saturated Tris-HCl buffer solution, under oxygen-saturated conditions, room temperature After stirring for 1 hour, dopamine hydrochloride is in-situ polymerized on the surface of commercial platinum carbon; in step (3): heating to 700° C. at a heating rate of 5° C. / min and then keeping it for 1 hour. A PtNiCoMnCe high-entropy alloy similar to Example 1 can be obtained.

Embodiment 3

[0035] On the basis of Example 1, different from Example 1, in step (1): in 100ml aqueous solution, add 1g of sodium dodecylbenzenesulfonate as a dispersant, then add 80mg of commercial platinum carbon and 50μl of pyrrole mono body, ultrasonically mixed for 30 minutes and then stirred at room temperature for 2 hours. Under ice bath conditions, 0.2M ferric chloride was used as an initiator to polymerize pyrrole on the surface of commercial platinum carbon in situ; in step (3): at 5°C / min The heating rate was heated to 700 °C and then kept for 1 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com