Sodium battery current collector as well as preparation method and application thereof

A technology for current collectors and sodium batteries, which is applied to the coating of electrode collectors, batteries, battery electrodes, etc. It can solve the problems of electrode volume change limitations, unstable interfaces, and complicated methods, and achieve improved wettability and easy scale. The effect of chemical production and growth inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A method for preparing a current collector of a sodium battery, comprising: coating a layer of gallium-based liquid metal at room temperature on the surface of metal aluminum, and then standing still for diffusion reaction to form an aluminum-gallium alloy layer on the surface of metal aluminum to obtain the current collector.

[0031] The sodium battery current collector prepared by the above preparation method comprises: metal aluminum and an aluminum-gallium alloy layer attached to the surface of the metal aluminum.

[0032] A highly stable sodium metal electrode, depositing a certain amount of sodium metal on the current collector by electrodeposition to form a sodium metal electrode.

[0033] The application of the above metal sodium electrode in the manufacture of sodium batteries, smart grids, electronic products, electric vehicles, and mobile energy storage equipment.

[0034] In some typical embodiments, the aluminum metal includes, but is not limited to: any o...

Embodiment 1

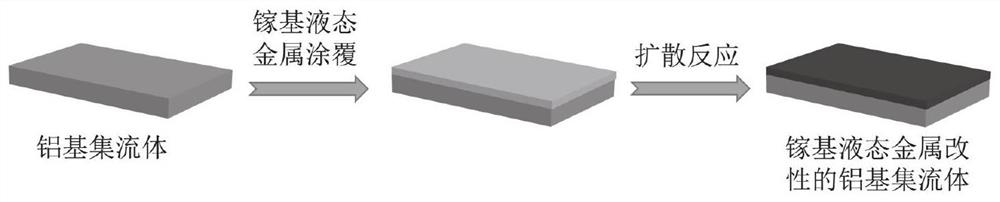

[0046] A preparation of a sodium battery current collector that inhibits the growth of sodium dendrites, comprising the steps of ( figure 1 ):

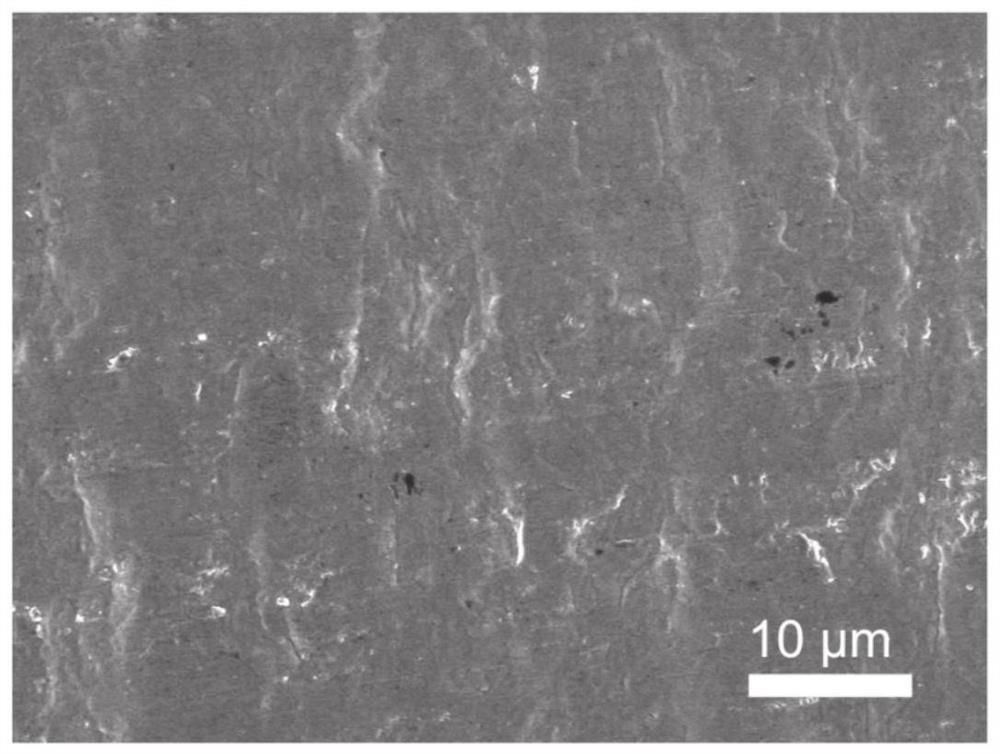

[0047] (1) Wipe the surface of the aluminum foil with absolute ethanol to remove impurities such as oil and dust. Its scanning electron microscope image is shown in figure 2 shown.

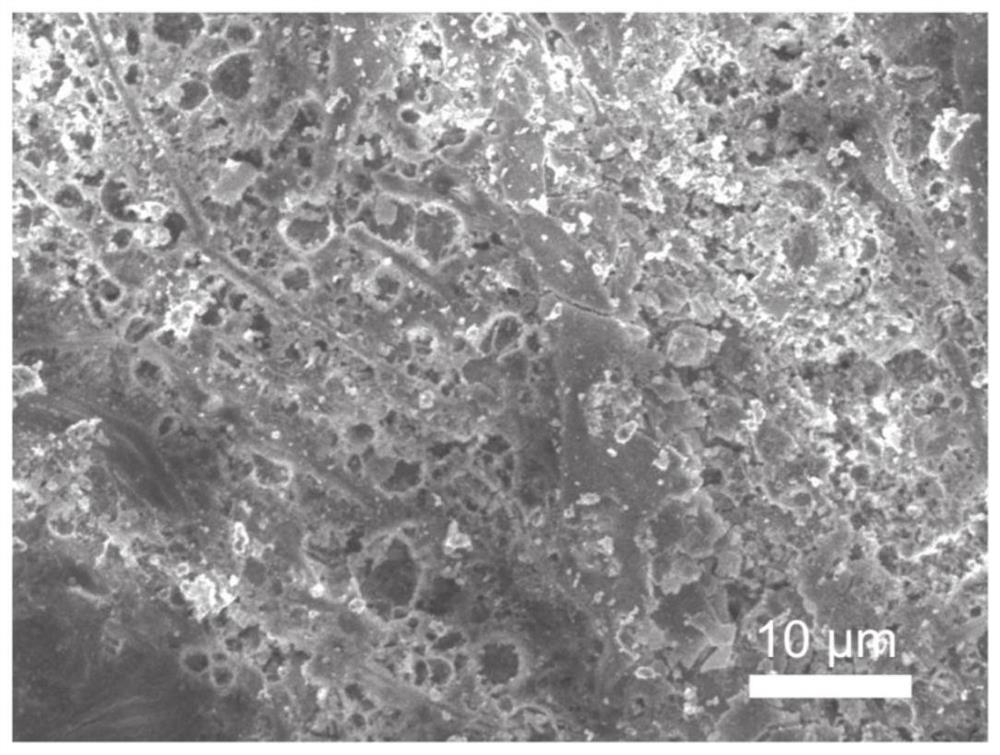

[0048] (2) Quickly apply a layer of GaInSnZn liquid metal on the surface of the cleaned aluminum foil with a small brush, and let it stand for 1 hour to react. Gallium loading on aluminum foil is 0.2mg / cm 2 . Its scanning electron microscope image is shown in image 3 shown.

[0049] (3) With the aluminum foil modified by GaInSnZn liquid metal as the current collector, and the metal sodium sheet as the counter electrode, assemble the CR2032 button cell in an inert atmosphere, and use 0.2mA / cm 2A current density of 2mAh / cm is deposited on the current collector 2 of sodium metal. Electrolyte is 1M NaPF 6 - EC / DEC (volume ratio 1:1) + 5% FEC. Its...

Embodiment 2

[0052] A preparation of a sodium battery current collector that inhibits the growth of sodium dendrites, comprising the steps of:

[0053] (1) Wipe the surface of the aluminum foil with absolute ethanol to remove impurities such as oil and dust.

[0054] (2) Quickly apply a layer of GaInSn liquid metal on the surface of the cleaned aluminum foil with a small brush, and let it stand for 1 hour to react. Gallium loading on aluminum foil is 0.2mg / cm 2 .

[0055] (3) Use the aluminum foil modified by GaInSn liquid metal as the current collector, and the metal sodium sheet as the counter electrode, assemble the CR2032 button battery in an inert atmosphere, and use 0.2mA / cm 2 A current density of 2mAh / cm is deposited on the current collector 2 of sodium metal. Electrolyte is 1M NaPF 6 - EC / DEC (volume ratio 1:1) + 5% FEC. The structure of the button cell includes positive electrode casing (stainless steel), negative electrode casing (stainless steel), gasket (stainless steel),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com