Ternary positive electrode material, preparation method and application thereof

A positive electrode material, positive electrode slurry technology, applied in positive electrodes, electrical components, battery electrodes and other directions, can solve the problems of low rate capacity, gas production, unstable cycle of ternary positive electrode materials, etc., to promote diffusion and simple preparation method , the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] Among the existing technical solutions, a technical solution provides a ternary positive electrode material and a preparation method thereof and a lithium ion battery, wherein the ternary positive electrode material is mainly composed of a high-nickel ternary material and a cobalt borate coating layer; The preparation method includes: after mixing the boron source and the cobalt source, sintering in a protective atmosphere to obtain cobalt borate; mixing cobalt borate and a high-nickel ternary material, and heating in an oxidizing atmosphere to obtain the ternary positive electrode Material. The preparation conditions of the method are relatively strict, and cobalt borate needs to be prepared under a high-temperature protective atmosphere, and the ternary material should be heat-treated under an oxidative atmosphere, which is not conducive to large-scale production.

[0038] Another technical solution provides a method for selectively coating the surface of high-nickel ...

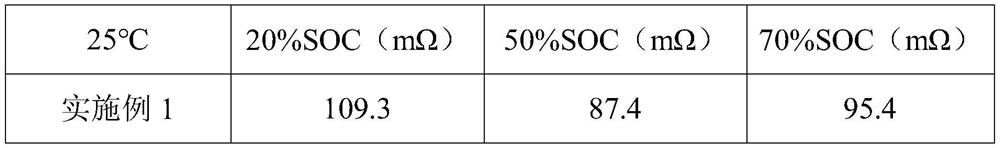

Embodiment 1

[0041] This embodiment provides a method for preparing a positive electrode sheet, the method comprising the following steps:

[0042] (1) LiNi 0.6 co 0.1 mn 0.3 o 2 Add Al when first heating up to 350°C at a heating rate of 3.5°C / min 2 o 3 , and then heated up to 650°C for the second time at a heating rate of 4.5°C / min and added H 2 W 2 o 7 , to obtain a ternary cathode material, the LiNi 0.6 co 0.1 mn 0.3 o 2 It is a secondary ball, the D50 particle size is 11μm, the Al 2 o 3 、H 2 W 2 o 7 and LiNi 0.6 co 0.1 mn 0.3 o 2 The mass ratio is 0.1:0.3:99.6;

[0043] (2) The mass ratio of ternary positive electrode material, conductive carbon black, conductive carbon tube, polyvinylidene fluoride and nitrogen methyl pyrrolidone is 97.5:1:0.5:1:40, and conductive carbon black, conductive carbon tube, polyvinylidene fluoride After mixing vinyl fluoride and nitrogen methyl pyrrolidone, stirring at 500 rpm for 2 hours to obtain a conductive slurry, mixing the obtain...

Embodiment 2

[0046] This embodiment provides a method for preparing a positive electrode sheet, the method comprising the following steps:

[0047] (1) LiNi 0.5 co 0.3 mn 0.2 o 2 Add Al when the temperature rises to 200°C at a heating rate of 2°C / min 2 o 3 , and then heated up to 500°C for the second time at a heating rate of 3°C / min and added H 2 W 2 o 7 , to obtain a ternary cathode material, the LiNi 0.5 co 0.3 mn 0.2 o 2 For the secondary ball, the D50 particle size is 2μm, the Al 2 o 3 、H 2 W 2 o 7 and LiNi 0.6 co 0.1 mn 0.3 o 2 The mass ratio is 0.1:0.1:99.98;

[0048] (2) The mass ratio of conductive carbon black, polyvinylidene fluoride and nitrogen methyl pyrrolidone is 90:0.5:0.5:20 for ternary positive electrode material, after mixing conductive carbon black, polyvinylidene fluoride and nitrogen methyl pyrrolidone Stirring at 500 rpm for 2 hours to obtain a conductive slurry, mixing the obtained conductive slurry with a ternary positive electrode material an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com