Method for improving adsorption density of self-assembled monomolecular carrier transport layer

A technology of self-assembled single molecule and transport layer, which is applied in coating, ion implantation plating, metal material coating process, etc., can solve the problems of forming holes, restricting the development of photovoltaic technology, complex doping process, etc., and achieve the improvement of adsorption effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

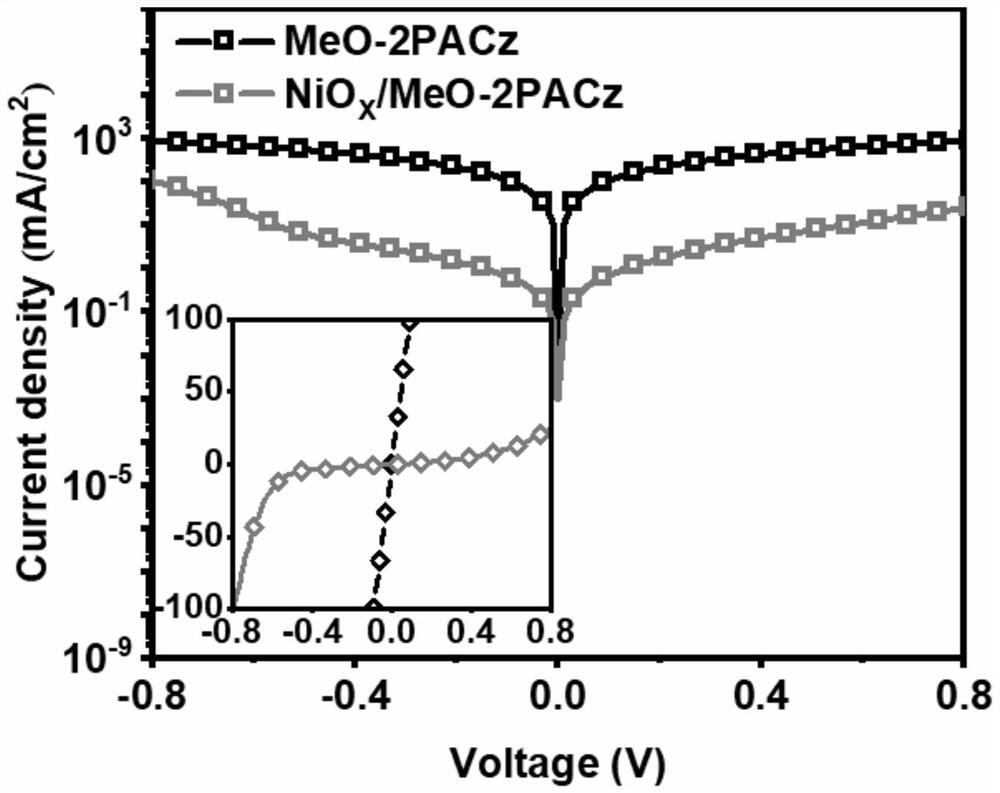

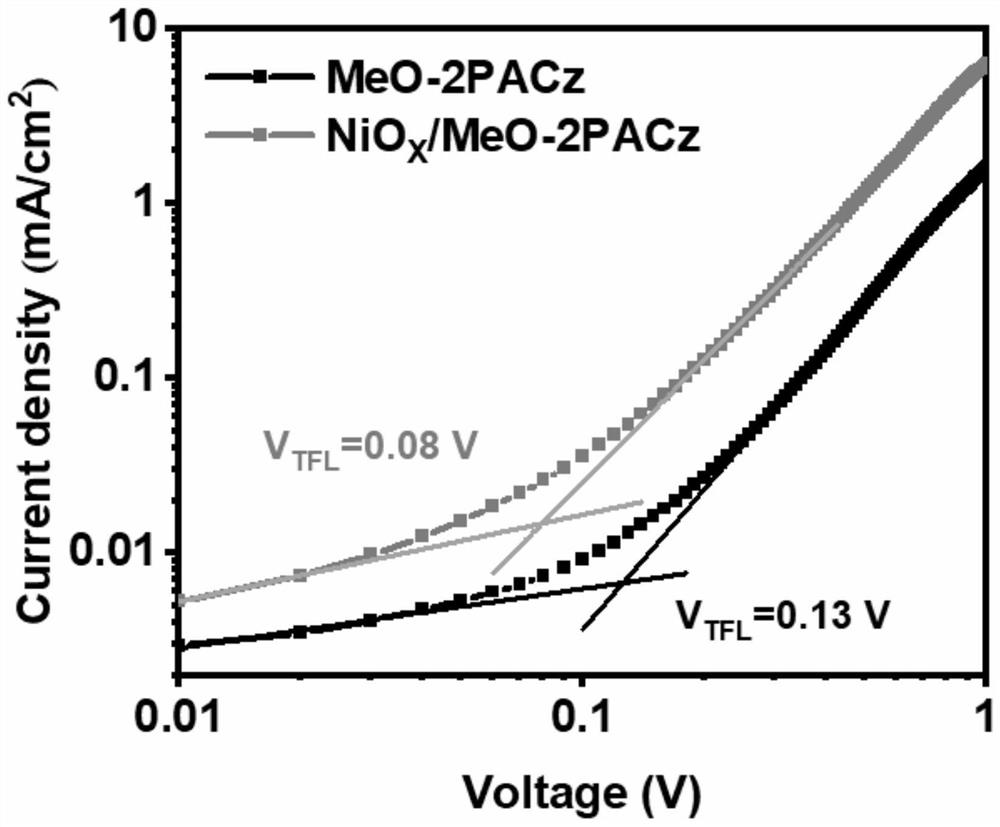

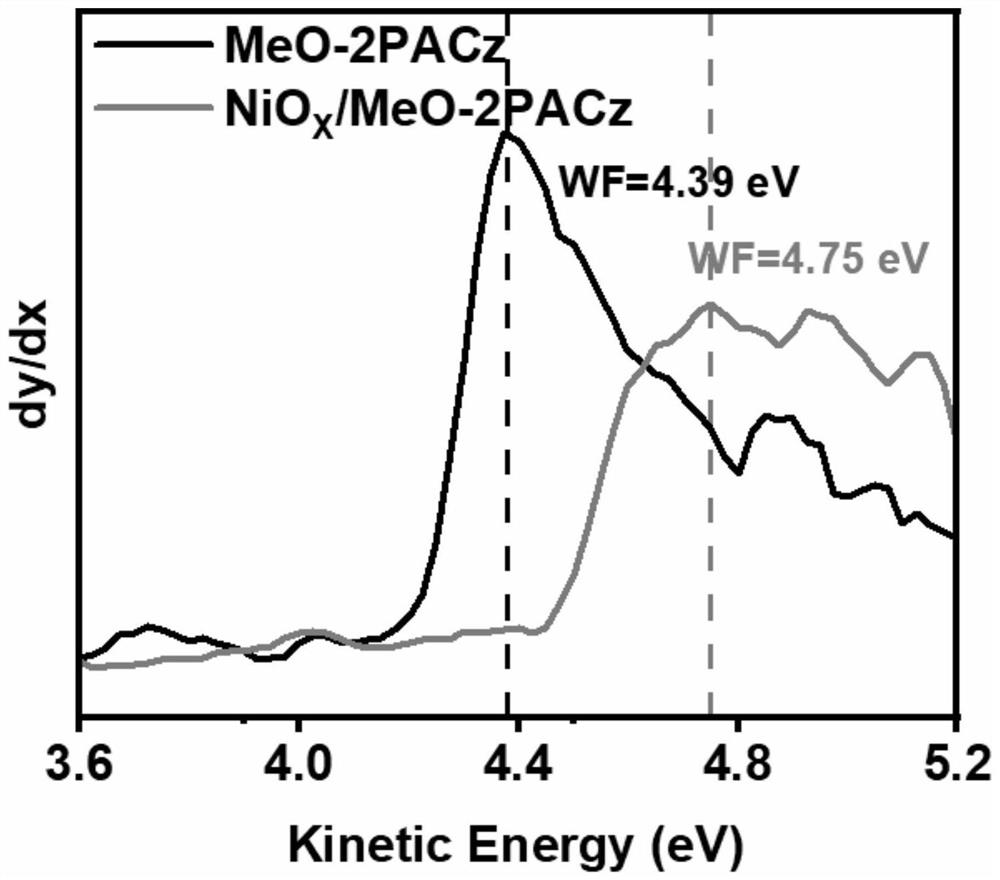

[0046] Example 1 of the present application provides the application of the method for increasing the adsorption density of the self-assembled monomolecular carrier transport layer in the preparation of perovskite solar cells:

[0047] Preparation of NiO on Clean Transparent Conductive Oxide (TCO) Substrates Using Magnetron Sputtering Coating Equipment X hole transport layer. When the working pressure is less than 4*10 -4 Pa, adjust O 2 / (Ar+O 2 ) ratio is 0 to 50%. The mechanism of magnetron sputtering means that electrons collide with argon atoms during the process of flying to the substrate under the action of an electric field, so that they are ionized to generate Ar + and new electronics. Ar + Under the action of an electric field, the surface of the cathode target is bombarded, and the generated neutral target atoms or molecules are deposited on the substrate to form a thin film. Therefore, the higher the argon content, the faster the growth rate of the film. The...

Embodiment 2

[0055] Example 2 of the present application provides the application of the method for increasing the adsorption density of the self-assembled monomolecular carrier transport layer in the preparation of organic solar cells:

[0056] Preparation of NiO on Clean Transparent Conductive Oxide (TCO) Substrates Using Magnetron Sputtering Coating Equipment X hole transport layer. When the working pressure is less than 4*10 -4 Pa, adjust O 2 / (Ar+O 2 ) ratio is 0 to 50%. The mechanism of magnetron sputtering means that electrons collide with argon atoms during the process of flying to the substrate under the action of an electric field, so that they are ionized to generate Ar + and new electronics. Ar + Under the action of an electric field, the surface of the cathode target is bombarded, and the generated neutral target atoms or molecules are deposited on the substrate to form a thin film. Therefore, the higher the argon content, the faster the growth rate of the film. The in...

Embodiment 3

[0060] Example 3 of the present application provides the application of the method for increasing the adsorption density of the self-assembled monomolecular carrier transport layer in the preparation of organic light-emitting diodes:

[0061] Preparation of NiO on Clean Transparent Conductive Oxide (TCO) Substrates Using Magnetron Sputtering Coating Equipment X hole transport layer. When the working pressure is less than 4*10- 4 Pa, adjust O 2 / (Ar+O 2 ) ratio is 0 to 50%. The mechanism of magnetron sputtering means that electrons collide with argon atoms during the process of flying to the substrate under the action of an electric field, so that they are ionized to generate Ar + and new electronics. Ar +Under the action of an electric field, the surface of the cathode target is bombarded, and the generated neutral target atoms or molecules are deposited on the substrate to form a thin film. Therefore, the higher the argon content, the faster the growth rate of the film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com