Injection control method and control device for methanol engine and vehicle

A control method and engine technology, applied in the fields of control devices, vehicles, and injection control methods, can solve the problems of high power requirements of heavy-duty methanol engines, large latent heat value of methanol fuel vaporization, and short spray evaporation time, so as to solve the problem of fuel vaporization mist. The effect of shortening the mixing time, reducing the phenomenon of wet wall in the cylinder, and improving the mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

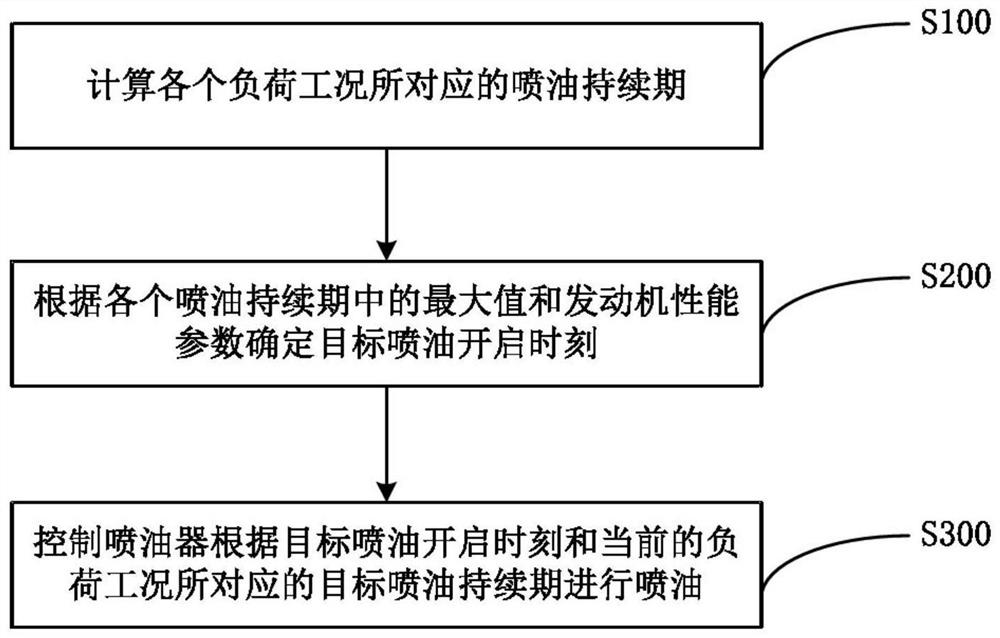

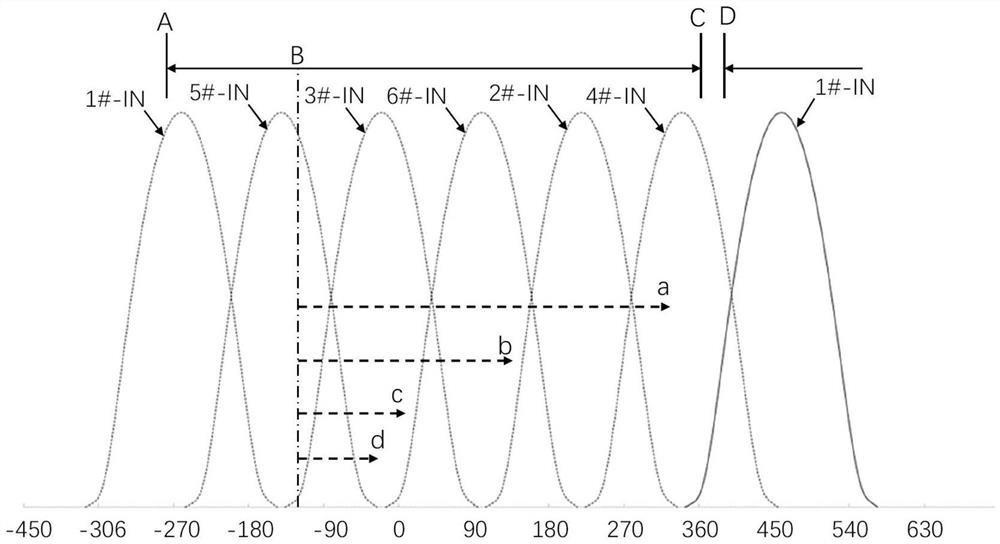

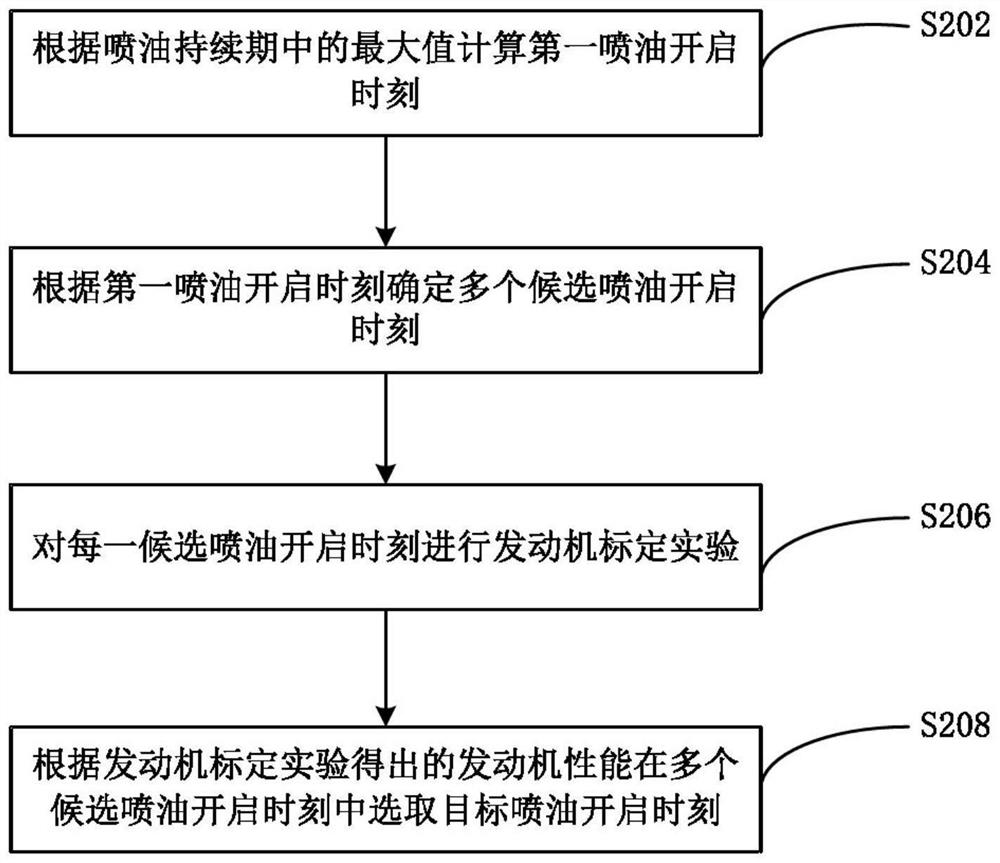

[0038] figure 1 is a flowchart of an injection control method according to an embodiment of the present invention. figure 2 is an injection timing chart of an injection control method according to an embodiment of the present invention. Such as figure 1 As shown, in one embodiment, the injection control method for methanol engine of the present invention comprises:

[0039] Step S100, calculating the fuel injection duration corresponding to each load condition.

[0040] The load working conditions refer to working conditions corresponding to different loads of the methanol engine, such as working at full load, working at 50% load, and so on.

[0041] Specifically, for each load condition, the corresponding air-fuel ratio can be calculated through the engine load value and the engine speed, and then the single-cylinder fuel injection quantity of each intake cycle of the engine can be calculated according to the air-fuel ratio, and then according to The crank angle can be c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com