Method for deep chemical treatment of papermaking wastewater sludge and use method

A technology of papermaking wastewater and deep chemistry, applied in papermaking, textile and papermaking, fiber raw material treatment, etc., can solve problems such as difficulty in sludge treatment, improve water filtration and dewatering capacity, increase fiber swelling and interweaving capacity, improve The effect of dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

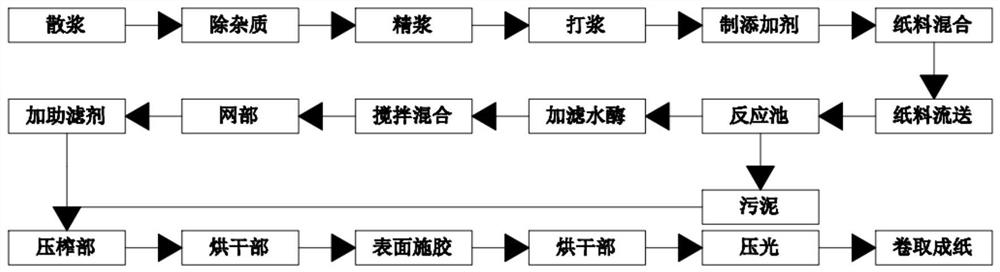

Image

Examples

Embodiment 1

[0030] A method for deep chemical treatment of papermaking wastewater sludge, comprising the following steps:

[0031] S1. The paper machine assembly line is followed by loose pulp, impurity removal, refined pulp, beating and additive mixing;

[0032] S2. The slurry after pulping and mixing is carried out to the stage of paper material flow;

[0033] S3. After the paper material flow is sent to the sludge reaction tank, water filter enzyme is added. The water filter enzyme is composed of cellulase, hemicellulase and pentose carbosidase. By using cellulase and hemicellulase Water filter enzyme made with pentose carbon sugar enzyme, which helps to peel off the cell wall;

[0034] S4, then carry out stirring and mixing reaction, the reaction temperature is 30 degrees Celsius, and the reaction time is 40 minutes;

[0035] S5. After the dewatering enzyme acts, the paper material enters the wire stage;

[0036] S6. Add flow aid and filter aid to react, the reaction temperature is...

Embodiment 2

[0044] A method for deep chemical treatment of papermaking wastewater sludge, comprising the following steps:

[0045] S1. The paper machine assembly line is followed by loose pulp, impurity removal, refined pulp, beating and additive mixing;

[0046] S2. The slurry after pulping and mixing is carried out to the stage of paper material flow;

[0047] S3. After the paper material flow is sent to the sludge reaction tank, water filter enzyme is added. The water filter enzyme is composed of cellulase, hemicellulase and pentose carbosidase. By using cellulase and hemicellulase Water filter enzyme made with pentose carbon sugar enzyme, which helps to peel off the cell wall;

[0048] S4, then carry out stirring and mixing reaction, the reaction temperature is 40 degrees Celsius, and the reaction time is 50 minutes;

[0049] S5. After the dewatering enzyme acts, the paper material enters the wire stage;

[0050] S6. Add flow aid and filter aid and react, the reaction temperature i...

Embodiment 3

[0058] A method for deep chemical treatment of papermaking wastewater sludge, comprising the following steps:

[0059] S1. The paper machine assembly line is followed by loose pulp, impurity removal, refined pulp, beating and additive mixing;

[0060] S2. The slurry after pulping and mixing is carried out to the stage of paper material flow;

[0061] S3. After the paper material flow is sent to the sludge reaction tank, water filter enzyme is added. The water filter enzyme is composed of cellulase, hemicellulase and pentose carbosidase. By using cellulase and hemicellulase Water filter enzyme made with pentose carbon sugar enzyme, which helps to peel off the cell wall;

[0062] S4, then carry out stirring and mixing reaction, the reaction temperature is 50 degrees Celsius, and the reaction time is 60 minutes;

[0063] S5. After the dewatering enzyme acts, the paper material enters the wire stage;

[0064]S6, adding flow aid and filter aid, reacting, the reaction temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com