A kind of aluminum magnesium silicon scandium zirconium alloy and preparation method thereof

A zirconium alloy, aluminum-magnesium-silicon technology, applied in the field of aluminum-magnesium-silicon-scandium-zirconium series alloys and its preparation, can solve problems such as difficulty in meeting design and use requirements, and achieve low alloying element content, inhibition of recrystallization, and simple composition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] The chemical composition and weight percentage of the aluminum-magnesium-silicon-scandium-zirconium alloy are one of the following three ratios:

[0034] The first proportion: Mg 0.5%~1.1%, Si 0.4%~1.2%, Sc 0.02%~0.25%, impurities Cu≤0.1%, Fe≤0.35%, other impurities individually≤0.05%, total amount≤0.15% , the remainder is Al;

[0035] The second proportion: Mg 0.5%~1.1%, Si 0.4%~1.2%, Zr 0.04%~0.18%, impurities Cu≤0.1%, Fe≤0.35%, other impurities individually≤0.05%, total amount≤0.15% , the remainder is Al;

[0036] The third proportion: Mg 0.5%~1.1%, Si 0.4%~1.2%, Sc 0.02%~0.25%, Zr 0.04%~0.18% and 0.08%≤Zr+Sc≤0.40%, impurity Cu≤0.1% , Fe≤0.35%, other impurities individually≤0.05%, the total amount≤0.15%, and the balance is Al.

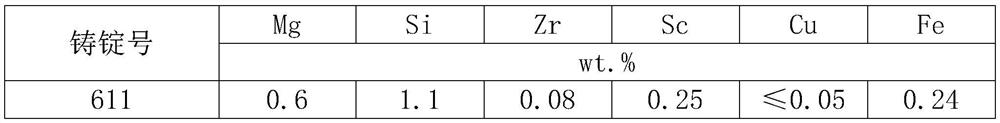

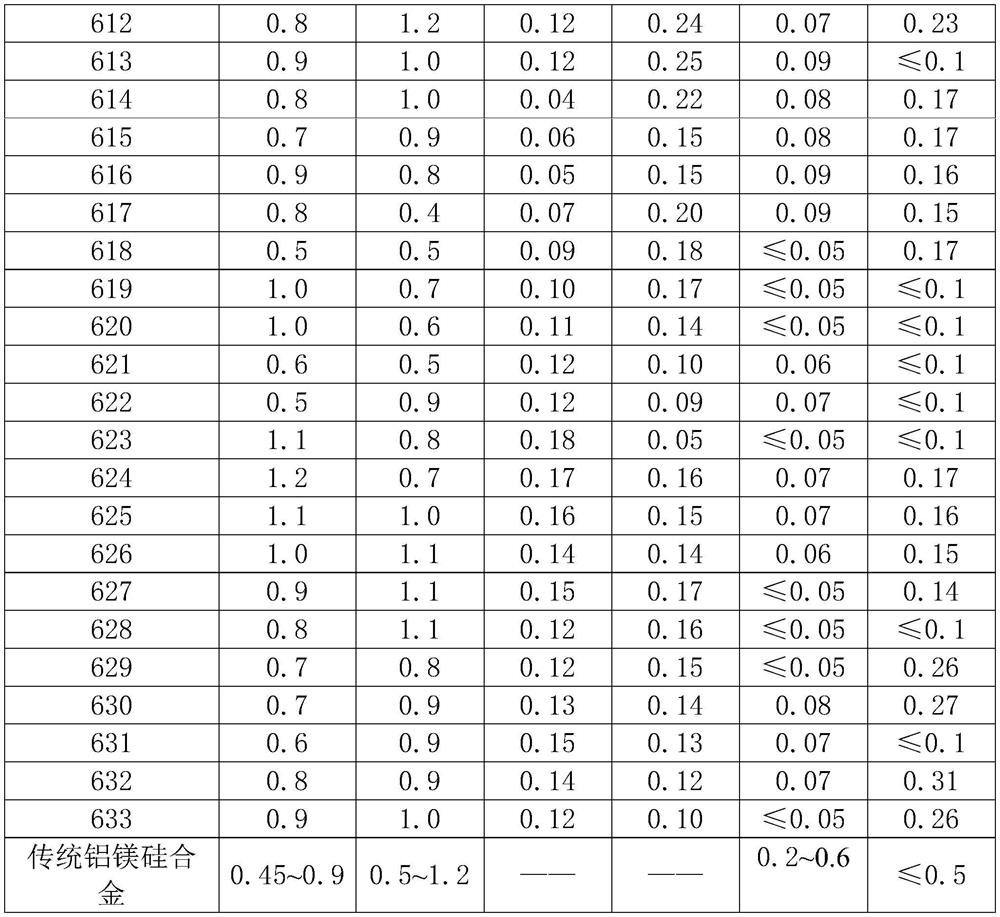

[0037] A φ320mm round ingot is prepared by the preparation method of the present invention, and the ingot composition is shown in Table 1.

[0038] Table 1 Ingot alloy composition weight percentage (%)

[0039]

[0040]

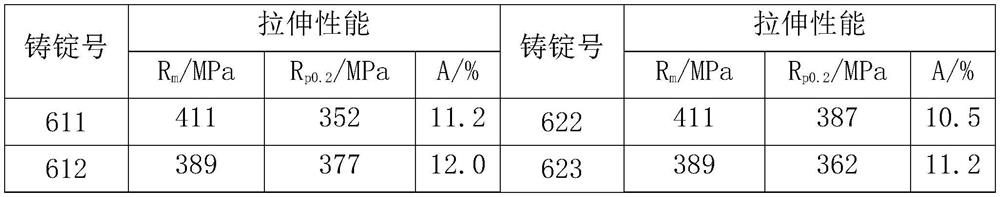

[0041] Af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com