Ceramic tile with metal flash large particles and preparation method thereof

A technology of metal glitter and glitter particles, which is applied in the field of architectural ceramics, can solve the problems that it is difficult to achieve metal glitter effect, the appearance of granite products is flat, and the stone details cannot be achieved, so as to achieve strong glitter effect, improve suspension performance, and bright color Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A ceramic tile with metallic flashing large particles, which is made by mixing green body materials and flashing particles, and the raw materials of the flashing particles include the following components in parts by mass:

[0034] Alloy metal material 85 parts,

[0035] Kaolin 15 parts,

[0036] 7 parts of wollastonite powder,

[0037] Suspension stabilizer 0.2 part,

[0038] Sodium tripolyphosphate 0.1 parts.

[0039] The alloy metal material includes metal material A, metal material B and metal material C with a mass ratio of 1:1:0.3. It should be noted that the metal material A, metal B and metal C of the present invention can be matched in any proportion, so as to achieve different flashing effects, which can truly reflect the diversity of stone luster.

[0040] The suspension stabilizer is polyamide.

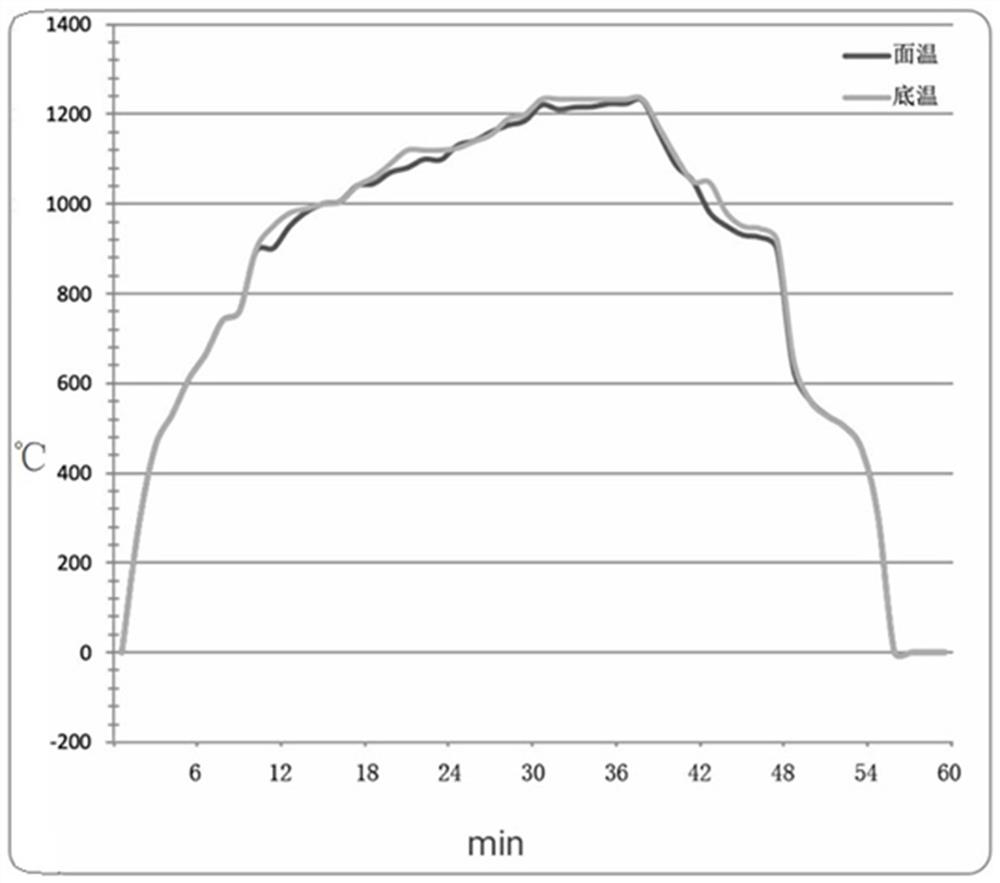

[0041] Further, chemical analysis was carried out on the three alloy metal materials of the glitter particles, and the chemical compositions are shown in Table...

Embodiment 2

[0063] A ceramic tile with metallic flashing large particles, which is made by mixing green body materials and flashing particles, and the raw materials of the flashing particles include the following components in parts by mass:

[0064] Alloy metal material 80 parts,

[0065] Kaolin 10 parts,

[0066] 10 parts of wollastonite powder,

[0067] Suspension stabilizer 0.3 part,

[0068] Sodium tripolyphosphate 0.05 part.

[0069] The alloy metal material includes metal material A, metal material B and metal material C with a mass ratio of 1:1:1. The suspension stabilizer is polyamide.

[0070] Further, chemical analysis was carried out on the three alloy metal materials of the glitter particles, and the chemical composition is shown in Table 1 of Example 1.

[0071] Further, the raw material of the green body material includes the following components in parts by mass: 24 parts of potassium sodium stone powder, 12 parts of potassium stone powder, 24 parts of aluminum sand, ...

Embodiment 3

[0086] A ceramic tile with metallic flashing large particles, which is made by mixing green body materials and flashing particles, and the raw materials of the flashing particles include the following components in parts by mass:

[0087] Alloy metal material 90 parts,

[0088] Kaolin 12 parts,

[0089] 7 parts of wollastonite powder,

[0090] Suspension stabilizer 0.1 parts,

[0091] Sodium tripolyphosphate 0.15 parts.

[0092] The alloy metal material includes metal material A, metal material B and metal material C with a mass ratio of 1:0.8:0.5. It should be noted that the metal material A, metal B and metal C of the present invention can be matched in any proportion, so as to achieve different flashing effects, which can truly reflect the diversity of stone luster. The suspension stabilizer is polyamide.

[0093] Further, chemical analysis was carried out on the three alloy metal materials of the glitter particles, and the chemical composition is shown in Table 1 of E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com