Nitrogen-containing compound, organic electroluminescent device comprising same and electronic device

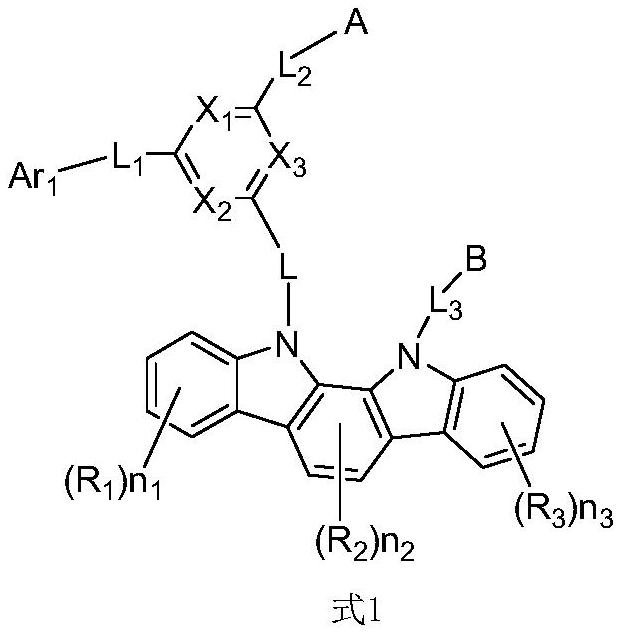

A technology of nitrogen compounds and chemical bonds, applied in the field of organic electroluminescent devices and electronic devices, to achieve excellent electron injection and transport characteristics, enhance the balance degree, and improve the effect of electron transport performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

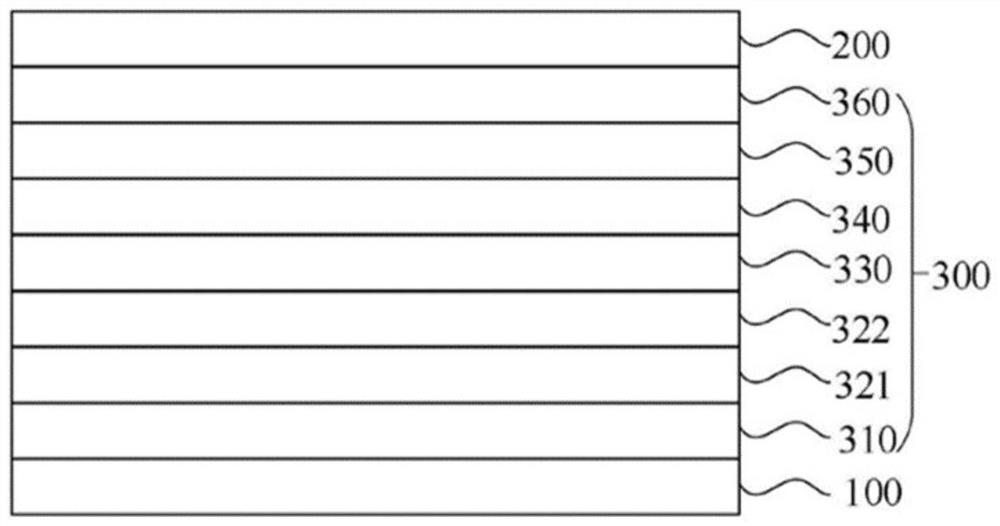

[0229] Green Organic Electroluminescent Devices

[0230] The anode is formed with indium tin oxide (ITO) on the substrate on which the reflective layer is formed, with a thickness of Cut into a size of 40mm×40mm×0.7mm, and prepare it into an experimental substrate with cathode, anode and insulating layer patterns by photolithography process, and clean the surface of ITO substrate with organic solvent to remove impurities on the surface; or use ultraviolet Ozone and O 2 :N 2 Plasma surface treatment to increase the work function of the anode.

[0231] Vacuum-evaporate PtPC on the anode of the substrate by PVD method to form a thickness of the hole injection layer, and the hole injection layer is evaporated The HT-01 forms the hole transport layer.

[0232] Evaporation on the hole transport layer The HT-02 forms a hole assisting layer.

[0233] On the hole assisting layer, compound A-1-1:GH-P:Ir(3mppy) 3 Co-evaporated at a ratio of 45%: 45%: 10%, forming a thickness ...

Embodiment 2-28

[0237] When forming the green light-emitting layer, the compounds shown in Table 11 were used instead of the compound A-1-1 in Example 1, and the organic electroluminescent device was fabricated by the same method as in Example 1.

Embodiment 29

[0253] Set the ITO thickness to The substrate was cut into a size of 40mm×40mm×0.7mm, and the photolithography process was used to prepare the experimental substrate with cathode, anode and insulating layer patterns, using ultraviolet ozone and O 2 :N 2 The plasma is used for surface treatment to remove surface particles and improve the anode work function.

[0254] Vacuum evaporation of PtPC on the substrate by PVD method to form a thickness of The hole injection layer, and HT-01 is evaporated on the hole injection layer to form a thickness of hole transport layer.

[0255] The thickness of evaporation on the hole transport layer is HT-02, forming a hole-assisting layer.

[0256] On the hole assisting layer, compound RH-P: Compound A-1-26: Ir(dmpq) 2 acac is co-evaporated at the ratio of 49%: 49%: 2% (evaporation rate), forming The organic electroluminescent layer (red emitting layer).

[0257] BCP and LiQ were mixed at a weight ratio of 1:1 and evaporated to for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com