Method for recycling copper and zinc in catalyst production wastewater

A technology for producing wastewater and catalysts, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve problems such as difficulty in recycling, pollution, and increased production costs, and achieve simple process, efficient enrichment, and stable operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

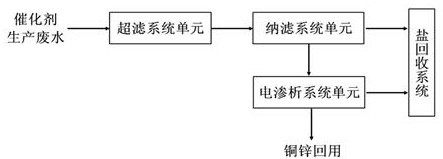

Image

Examples

Embodiment 1

[0023] The catalyst production wastewater material was taken from a domestic manufacturer, and the sample material conditions are shown in Table 1:

[0024] Table 1 The material situation of catalyst production wastewater in a domestic manufacturer

[0025] Test items SS Na +

NO 3 -

Cu 2+

Zn 2+

unit mg / L mg / L mg / L mg / L mg / L value 50 1000 3000 0.1 0.1

[0026] Wastewater material enters the hollow fiber ultrafiltration system unit, the operating temperature is 20°C, the control operating pressure is 0.1 MPa, the membrane surface flow velocity is 2 m / s, and the membrane flux is 60 L / (m 2 h), after testing, the water produced by the ultrafiltration unit: SS=0.05 mg / L.

[0027] The product water enters the roll-type nanofiltration membrane system unit, the operating temperature is 20°C, the operating pressure is 0.5 MPa, the membrane surface flow velocity is 2m / s, and the membrane flux is 30 L / (m 2 h), the recover...

Embodiment 2

[0030] The methanol synthesis catalyst waste water material is taken from a domestic manufacturer, and the sample material conditions are shown in Table 2:

[0031] Table 2 The material situation of catalyst production wastewater in a domestic manufacturer

[0032] Test items SS Na +

NO 3 -

Cu 2+

Zn 2+

unit mg / L mg / L mg / L mg / L mg / L value 100 5000 15000 8 5

[0033] The waste water material enters the spiral ultrafiltration membrane system unit, the operating temperature is 35°C, the control operating pressure is 0.5 MPa, the membrane surface flow velocity is 3 m / s, and the membrane flux is 300 L / (m 2 h), after testing, the water produced by the ultrafiltration unit: SS=0.08 mg / L.

[0034] The product water enters the flat-panel nanofiltration membrane system unit, the operating temperature is 30°C, the operating pressure is 3 MPa, the membrane surface flow velocity is 3m / s, and the membrane flux is 60 L / (m 2 h...

Embodiment 3

[0037] The methanol synthesis catalyst waste water material is taken from a domestic manufacturer, and the sample material conditions are shown in Table 3:

[0038] Table 3 Situation of catalyst production waste water materials of a domestic manufacturer

[0039] Test items SS Na +

NO 3 -

Cu 2+

Zn 2+

unit mg / L mg / L mg / L mg / L mg / L value 50 10000 30000 20 20

[0040] Wastewater material enters the coiled ultrafiltration membrane system unit, the operating temperature is 50 °C, the control operating pressure is 1 MPa, the membrane surface flow rate is 5 m / s, and the membrane flux is 600 L / (m 2 h), after testing, the water produced by the ultrafiltration unit: SS=0.05 mg / L.

[0041] The product water enters the ceramic tubular nanofiltration membrane system unit, the operating temperature is 50 °C, the operating pressure is 5 MPa, the membrane surface flow velocity is 5 m / s, and the membrane flux is 80 L / (m 2 h), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com