Refining device pipe network integrity management level intelligent evaluation method

A technology with management level and integrity, applied in electrical digital data processing, design optimization/simulation, instruments, etc., can solve problems such as poor generalization ability, low convergence efficiency, large neural network structure, etc., and achieve good economic value and social value. The effect of value, efficient and accurate grasp, and high convergence rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

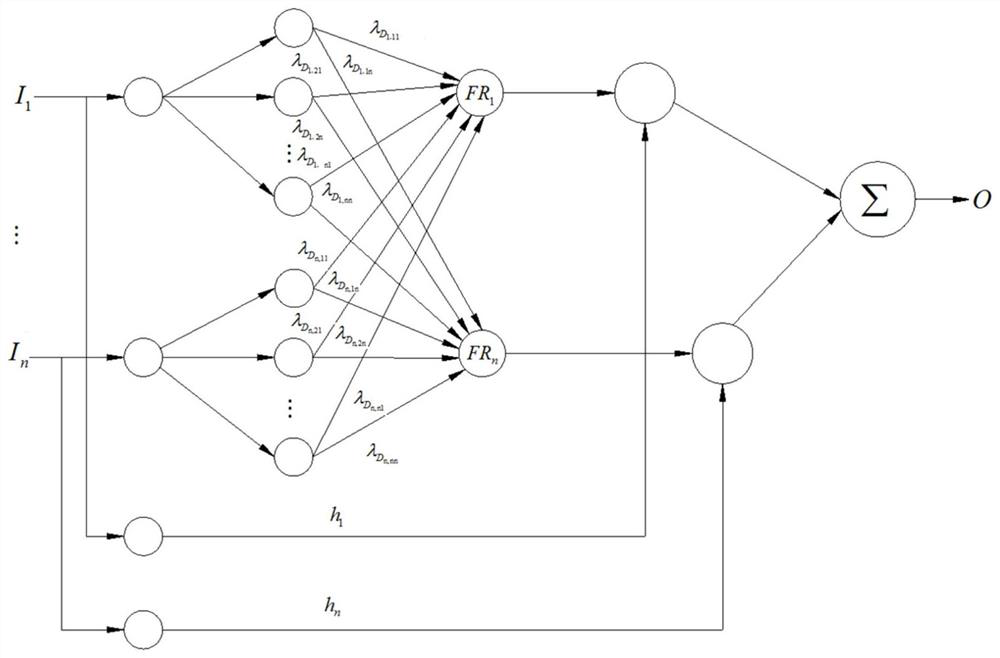

[0047] Technical scheme of the present invention comprises the steps:

[0048] Step 1: Build a pipeline integrity management system for refining and chemical equipment: Integrate safety standardization specifications and HSE management system, use the HSE management system as the framework, from data collection, high consequence area identification, risk assessment, integrity assessment, risk reduction The integrity management system of the refining and chemical plant pipeline network is constructed from the perspective of maintenance and maintenance. The integrity management system constructed can not only respond to the policies of the supervision department, but also follow the conventional management mode of the oil and gas industry and build an advanced pipeline network management mode. Through advanced technology, improve the technical level of petrochemical enterprises, reduce the incidence of accidents, and promote economic development.

[0049] The specific steps to bui...

specific Embodiment

[0087] A specific example is as follows:

[0088] In the embodiment, the super wavelet adopts the contour wave, the intelligent algorithm selects the wolf pack algorithm, and constructs a fuzzy contour wave neural network optimized by the wolf pack algorithm to evaluate the integrity management level of the pipe network of a polypropylene plant in a petrochemical company. Taking the whole month as an evaluation cycle, select the relevant data of the pipe network integrity management of the polypropylene plant of the petrochemical company from January 2018 to June 2021, a total of 30 sets of data, the first 24 sets of data as training samples, and the last 6 sets of data as a test sample.

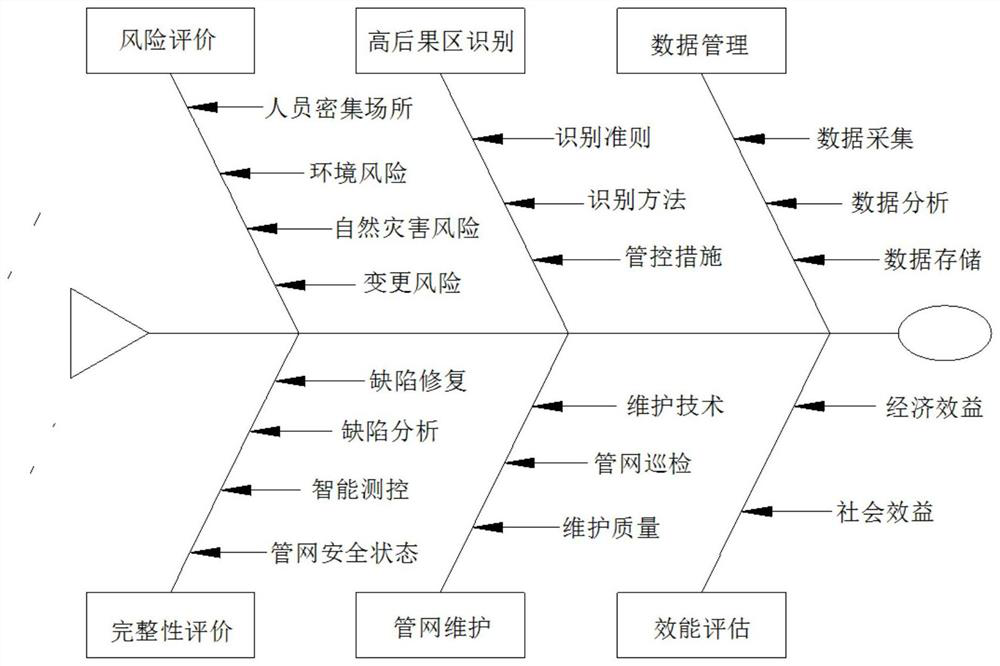

[0089] Through on-site research, expert interviews and questionnaire surveys were used to discover the main influencing factors of the integrity management level of the polypropylene plant pipe network, and the fishbone analysis method was used to determine the evaluation indicators of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com