Formwork-erecting-free cast-in-situ inverted trapezoidal composite beam and construction method thereof

A composite beam and formwork-free technology, which is applied in the direction of load-bearing elongated structural members, buildings, building reinforcements, etc., can solve the problems of insufficient material strength, impact on concrete vibration, and construction quality problems. Achieve the effects of reducing the binding workload, increasing the floor height and high assembly degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

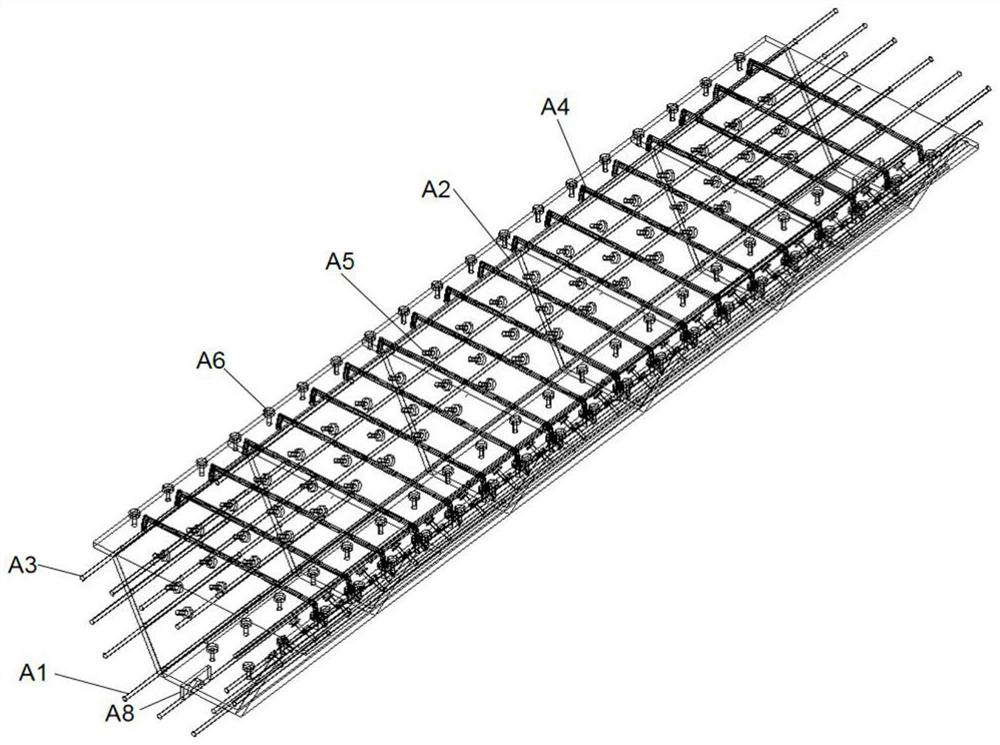

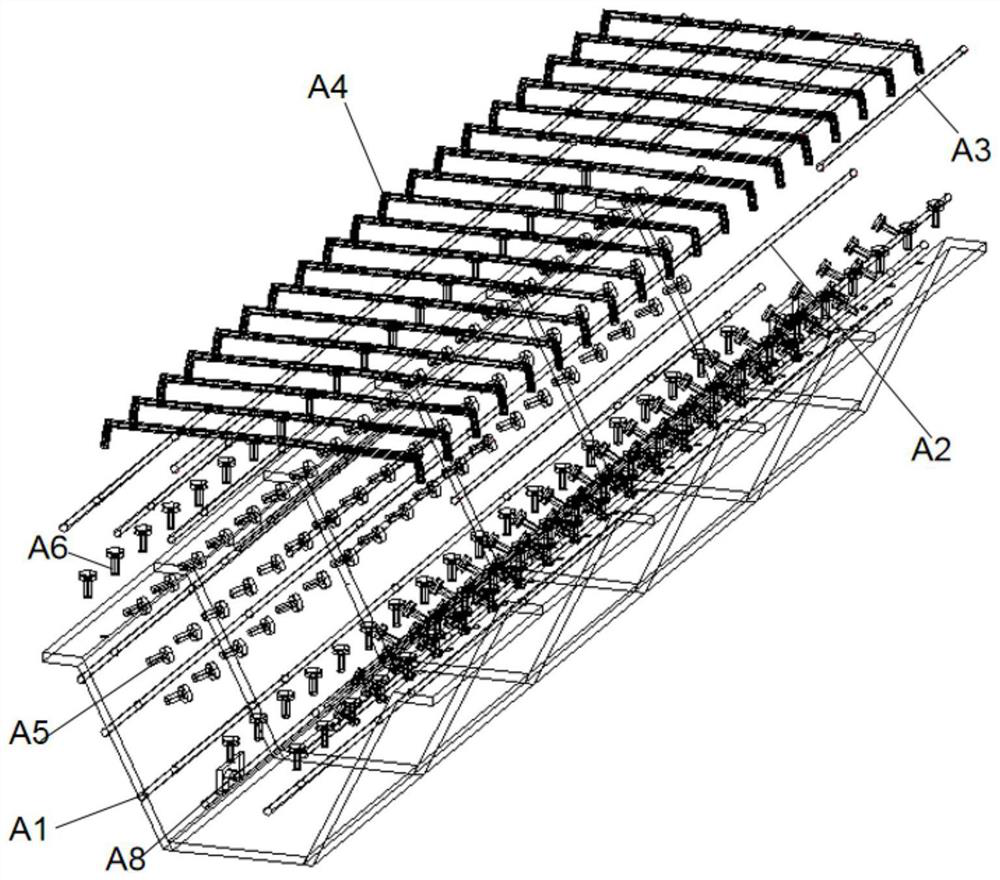

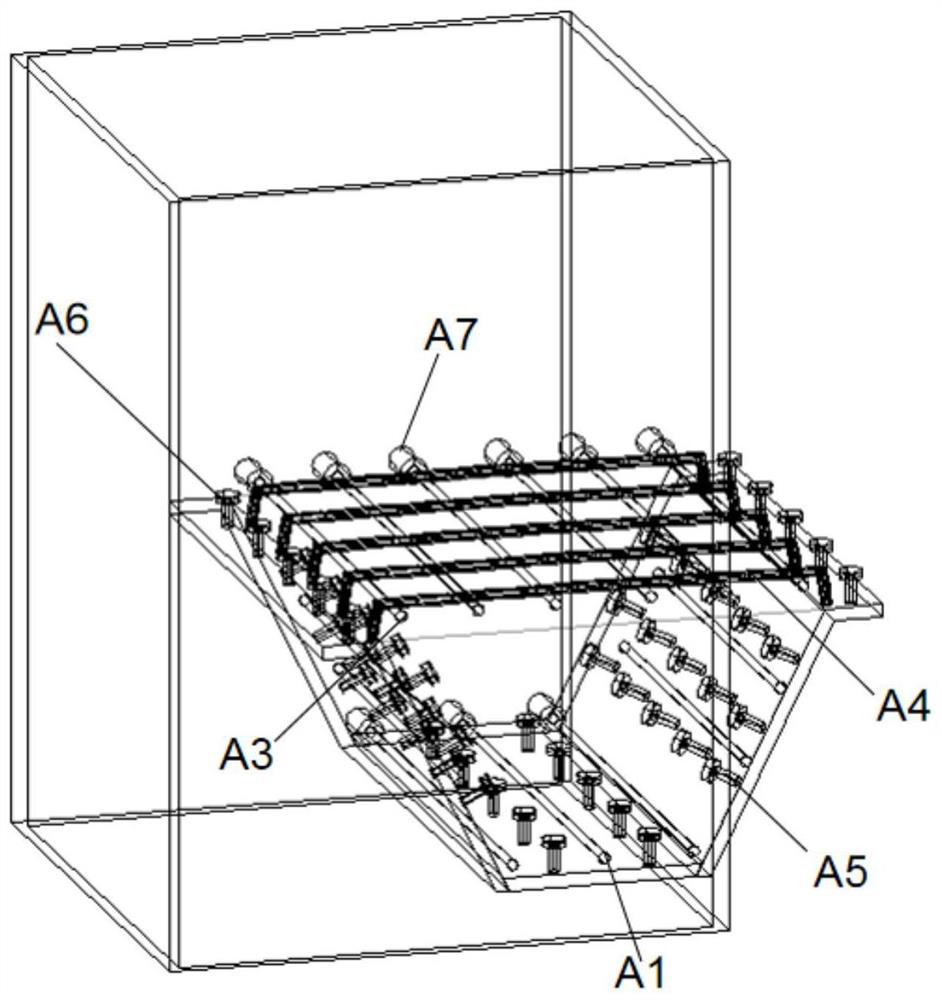

[0038] Determine the specific section size and length of the steel plate according to the column distance and beam section size, and then bend and form the steel plate in the mid-span and corbel section of the composite beam; weld the A5 internal wall plate studs to the internal wall plate of the steel plate at even intervals, The studs A6 of the horizontal flanging floor slab are also welded on the horizontal flanging plate of the steel plate at even intervals in the same way, and the studs are arranged symmetrically and evenly with respect to the axis of the inverted trapezoidal steel beam; The sleeve A7 or the connecting plate of the steel bar is welded to the frame column; the stirrup A4 at the top of the composite beam is welded to the horizontal flanging plate at the top of the integrated bent steel plate at the factory, and the side of the lower flange hanging plate A8 is integrated at the factory Weld the lower flange at the bottom of the middle section of the bent stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com