Integrated prefabricated slab

A technology that integrates prefabricated slabs and concrete slabs. It is applied to floors, building components, and structural elements. It can solve the problems of easy displacement of additional steel bars, difficulty in fixing additional steel bars, and inconformity with automated production, so as to reduce the workload of steel bar binding. , Reduce the cost of floor support, and avoid the effect of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

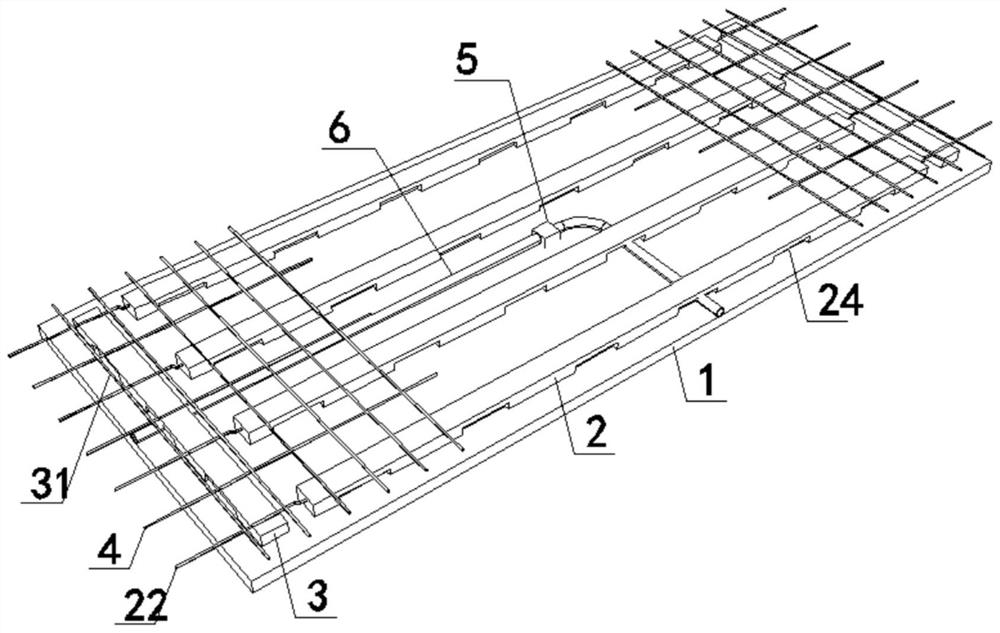

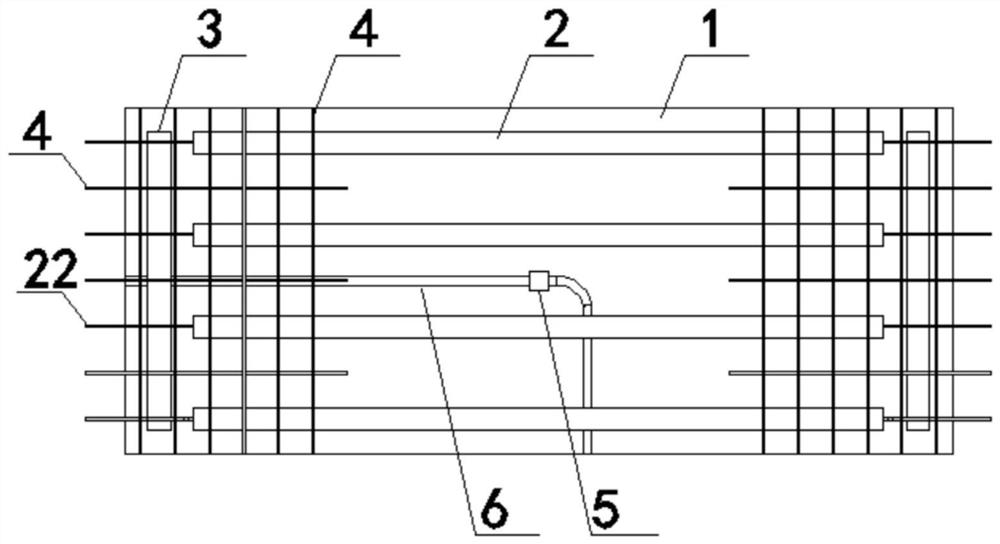

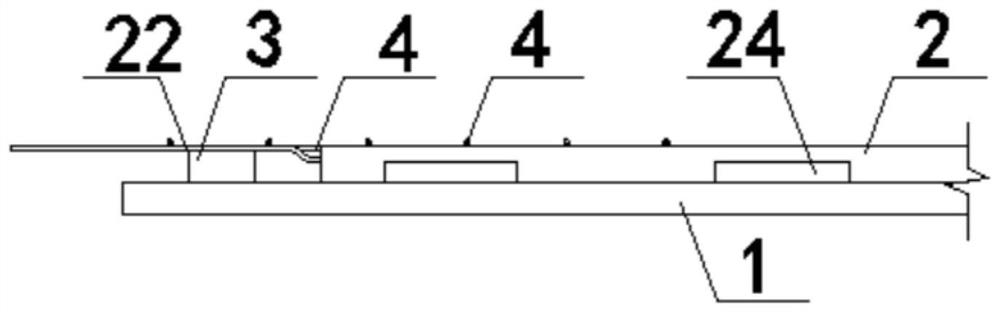

[0037] Such as Figure 1~6 As shown, an integrated integrated prefabricated slab disclosed by the present invention has additional ribs and pipelines integrated in the prefabricated slab, and its structure includes a concrete floor 1, a plurality of longitudinal concrete ribs 2, two sets of transverse concrete ribs 3 and steel mesh Sheet 4, the inside of the concrete floor is equipped with steel mesh, and the whole is a structure with no reinforcement around it. A plurality of longitudinal concrete ribs are arranged on the concrete floor in parallel and equally spaced, and two sets of transverse concrete ribs are arranged on the concrete floor. At both ends of the ribs, steel mesh sheets are laid on the surfaces of both ends of the longitudinal concrete ribs, and bound with the main bars extending from the ends of the longitudinal concrete ribs.

[0038] Specifically, the inside of the longitudinal concrete rib is provided with a ladder bar 21, the two ends of the ladder bar a...

no. 2 example

[0043] Such as Figure 7-9 As shown, it is another structural form of an integrated integrated prefabricated panel disclosed by the present invention. Compared with the structure of the first embodiment, two sets of transverse concrete ribs are removed, but two adjacent longitudinal ribs Concrete blocks 7 are set between the concrete ribs, which have the same effect as the transverse concrete ribs, not only supporting the steel mesh, but also strengthening the overall rigidity of the prefabricated slab. The other structures are consistent with the first embodiment, so no Too much repetition.

no. 3 example

[0045] Such as Figure 10 As shown, it is the third structural form of an integrated integrated prefabricated slab disclosed by the present invention, which uses the concrete blocks in the second embodiment even at the two ends of the longitudinal concrete ribs to form a structure for the reinforcement mesh and the main reinforcement. To the load-bearing role, it also strengthens the overall rigidity of the prefabricated panel.

[0046] The integrated integrated prefabricated slab disclosed by the present invention not only improves the rigidity of the whole prefabricated slab, but also reduces its cost and ensures the connection stability of the subsequent concrete pouring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com