Foundation ring bottom flange reinforcement method and steel bar assembly

A technology of foundation ring and circumferential steel bars, applied in the installation/support of wind turbine configuration, wind power generation, etc., can solve the problems of wind turbine foundation shaking, hidden dangers, easy cracking, etc. state, the effect of relieving excessive tensile stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A reinforcement method for a foundation ring bottom flange, comprising the following steps:

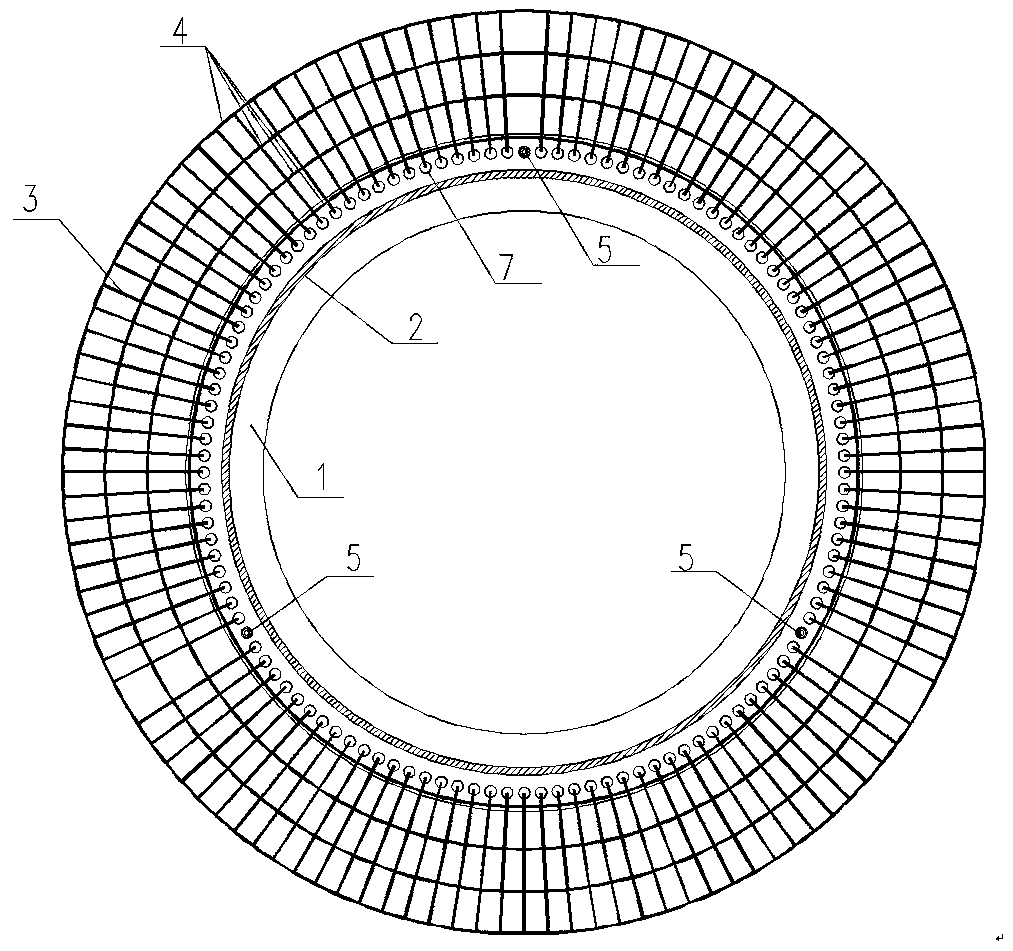

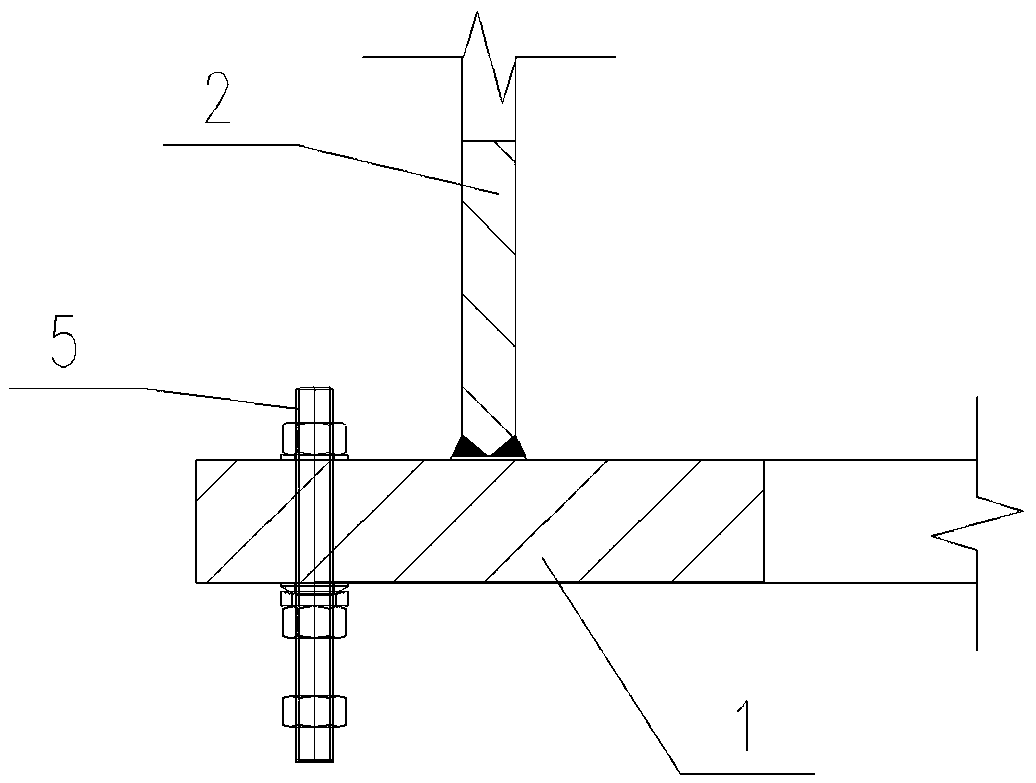

[0021] A new opening 7 is opened on the outer side of the base ring bottom flange 1;

[0022] U-shaped radial steel bars 3 that open outwards are arranged through the newly added openings 7;

[0023] Circumferential reinforcing bars 4 are respectively arranged in the upper and lower parallel sections passing through the U-shaped radial reinforcing bars 3 .

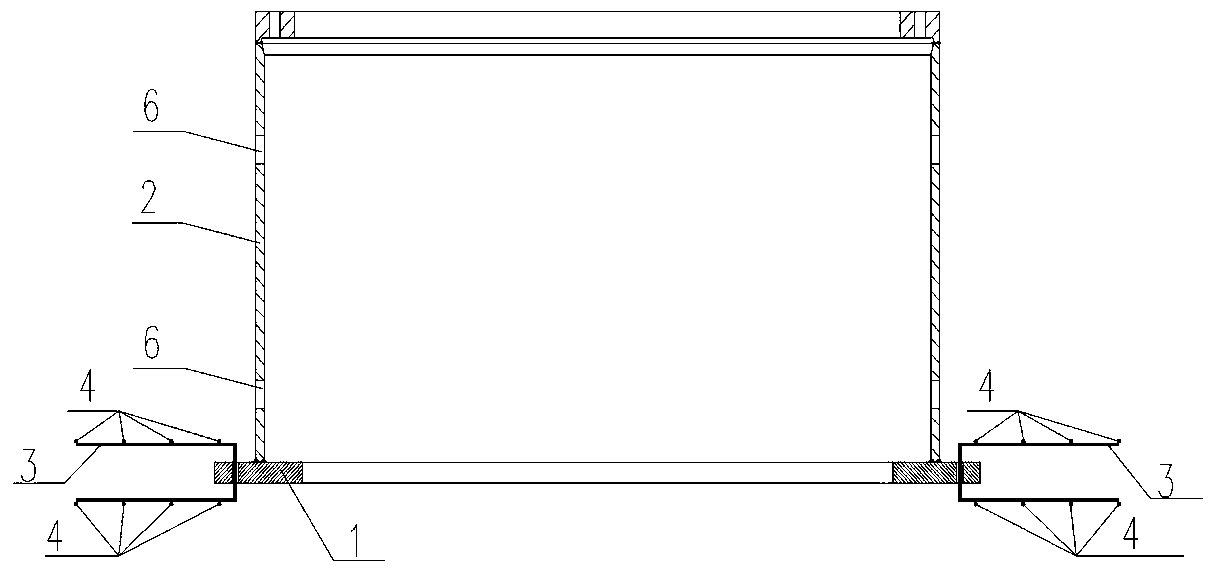

[0024] Such as figure 1 , figure 2 As shown, it is a steel bar assembly made by adopting the reinforcement method of the foundation ring bottom flange of the present invention. Directional reinforcing bars 3, circumferential reinforcing bars 4 respectively arranged in the upper and lower parallel sections of the U-shaped radial reinforcing bars 3.

[0025] There are 3 original openings on the outer side of the base ring bottom flange 1, and 117 new openings 7, all 120 openings are evenly distributed in a ring shape, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com