Engine sound insulation pad and preparation method thereof

A sound insulation pad and engine technology, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of low flame retardancy and heat resistance, general sound insulation effect of engine sound insulation pads, and inability to meet the long-term use of sound insulation pads, etc., to achieve Excellent flame retardancy and heat resistance, good sound insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation method of the engine sound insulation pad of the present embodiment, it may further comprise the steps:

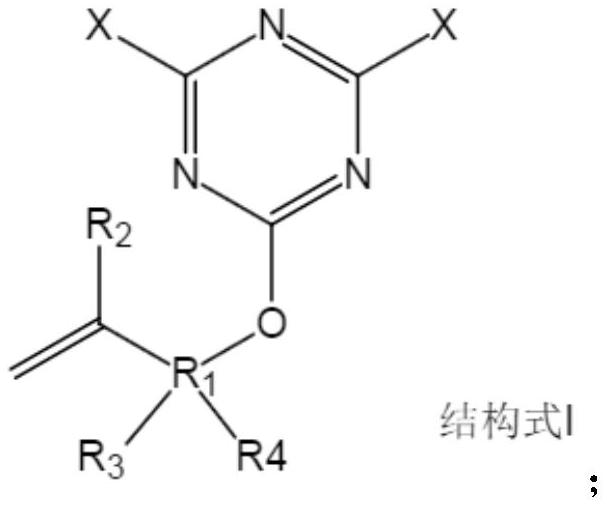

[0031] Step S1: Under the protection of inert gas nitrogen, the 2,4,6-tribromo-1,3,5-triazine and propenyl alcohol are stirred and dissolved in THF (tetrahydrofuran) solvent at a molar ratio of 1:1, Then add a catalyst and reflux for 24 hours at a temperature of 10°C. After distillation under reduced pressure, a triazine derivative shown in structural formula I is obtained; the 2,4,6-tribromo-1,3,5-triazine The mass ratio to the catalyst is 100:0.5; the catalyst is composed of an aqueous solution of sodium bicarbonate added with an appropriate amount of hydroxypropyl-β-cyclodextrin. The molar concentration of the sodium bicarbonate is 0.5mol / L; the added amount of the hydroxypropyl-β-cyclodextrin accounts for 0.5wt% of the total mass of the sodium bicarbonate aqueous solution;

[0032]

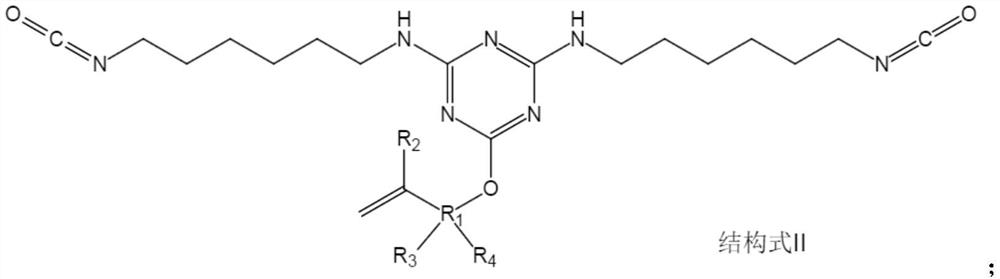

[0033] Step S2: Under the protection of inert gas nitrogen,...

Embodiment 2

[0039] The preparation method of the engine sound insulation pad of the present embodiment, it may further comprise the steps:

[0040] Step S1: Under the protection of inert gas nitrogen, the 2,4,6-tribromo-1,3,5-triazine and 2-methallyl alcohol were stirred and dissolved in THF ( Tetrahydrofuran (THF) solvent, then add a catalyst and reflux for 48 hours at a temperature of 10° C. After distillation under reduced pressure, a triazine derivative shown in structural formula I is obtained; the 2,4,6-tribromo-1,3 , The mass ratio of 5-triazine to the catalyst is 100:1.5; the catalyst is composed of an aqueous sodium bicarbonate solution added with an appropriate amount of hydroxypropyl-β-cyclodextrin. The molar concentration of the sodium bicarbonate is 0.8mol / L; the added amount of the hydroxypropyl-β-cyclodextrin accounts for 1wt% of the total mass of the sodium bicarbonate aqueous solution;

[0041]

[0042] Step S2: Under the protection of inert gas nitrogen, the triazine...

Embodiment 3

[0048] The preparation method of the engine sound insulation pad of the present embodiment, it may further comprise the steps:

[0049] Step S1: Under the protection of inert gas nitrogen, the molar ratio of 2,4,6-trichloro-1,3,5-triazine and 2-methyl-3-butene-1-ol is 1: 1 was stirred and dissolved in THF (tetrahydrofuran) solvent, then a catalyst was added and the temperature was 25° C. for reflux reaction for 48 hours. After vacuum distillation, the triazine derivative shown in structural formula I was obtained; the 2,4,6- The mass ratio of trichloro-1,3,5-triazine to the catalyst is 100:5; the catalyst is composed of an aqueous sodium bicarbonate solution added with an appropriate amount of hydroxypropyl-β-cyclodextrin. The molar concentration of the sodium bicarbonate is 1.2mol / L; the added amount of the hydroxypropyl-β-cyclodextrin accounts for 1.5wt% of the total mass of the sodium bicarbonate aqueous solution;

[0050]

[0051] Step S2: Under the protection of inert...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com