Hydroximic acid sulfonic acid compound as well as preparation method and application thereof

A hydroxamic acid sulfonic acid, the technology of hydroxamic acid sulfonic acid, applied in the direction of sulfonic acid preparation, organic chemistry, flotation, etc., can solve the problem of insufficient performance of fatty acid collectors, weak ability to resist calcium and magnesium ions, and chemical consumption Large and other problems, to achieve excellent flotation effect, less reagent consumption, excellent flotation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

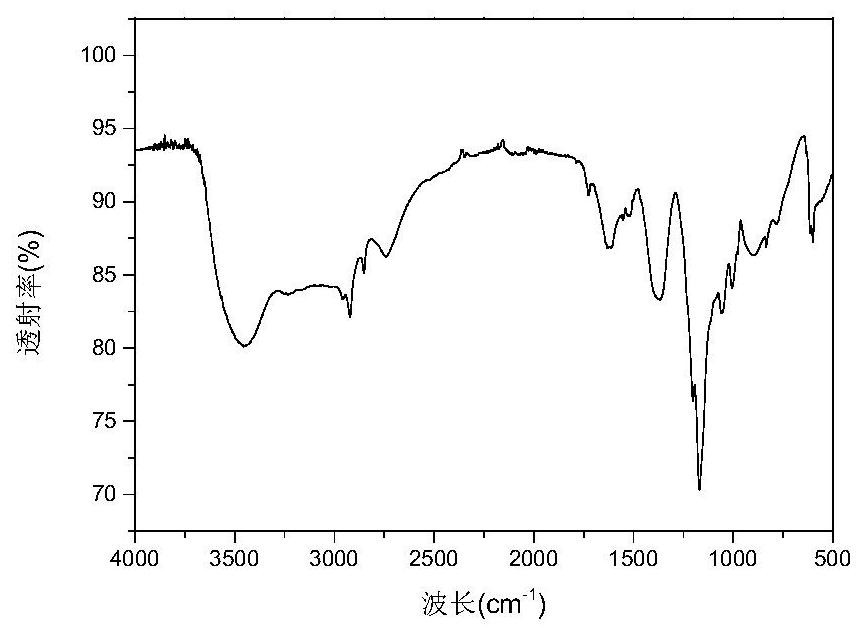

[0060] The present embodiment provides a hydroxamic acid sulfonic acid compound: 1-(hydroxyamino)-1-oxopentadecane-2-sulfonic acid, the preparation process of which is as follows:

[0061] Mix 20.0g sodium 1-methoxy-1-oxopentadecane-2-sulfonate and 15mL 20% hydroxylamine solution-1, then add 5.0g NaOH catalyst, heat to 35°C, react for 12 hours, add concentrated sulfuric acid to adjust pH to 7, suction filtration and distilled water to remove inorganic salts and raw material sulfonates to obtain 15.4 g of a mixture of 1-(hydroxyamino)-1-oxopentadecane-2-sulfonic acid, and the mixture was calibrated using Kjeldahl method N content, the yield was 52.6%.

Embodiment 2

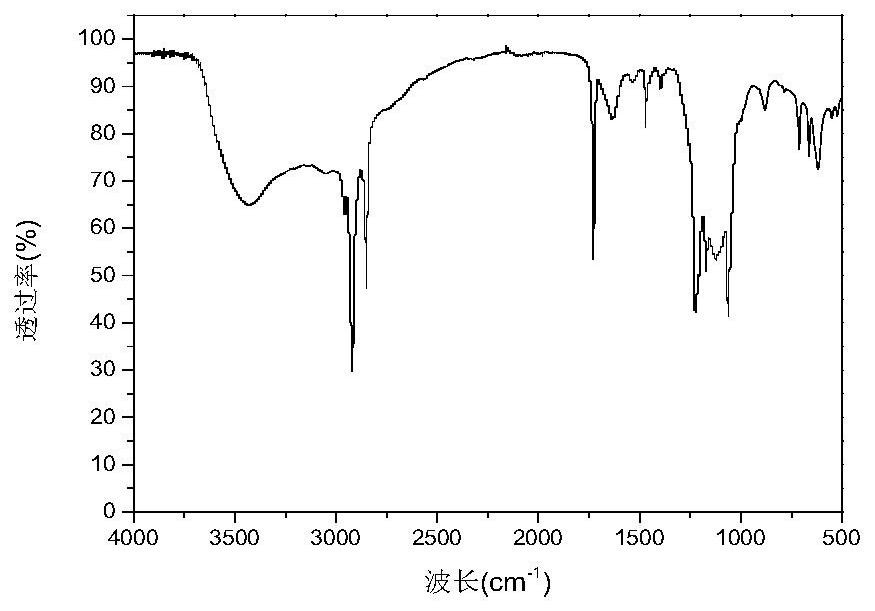

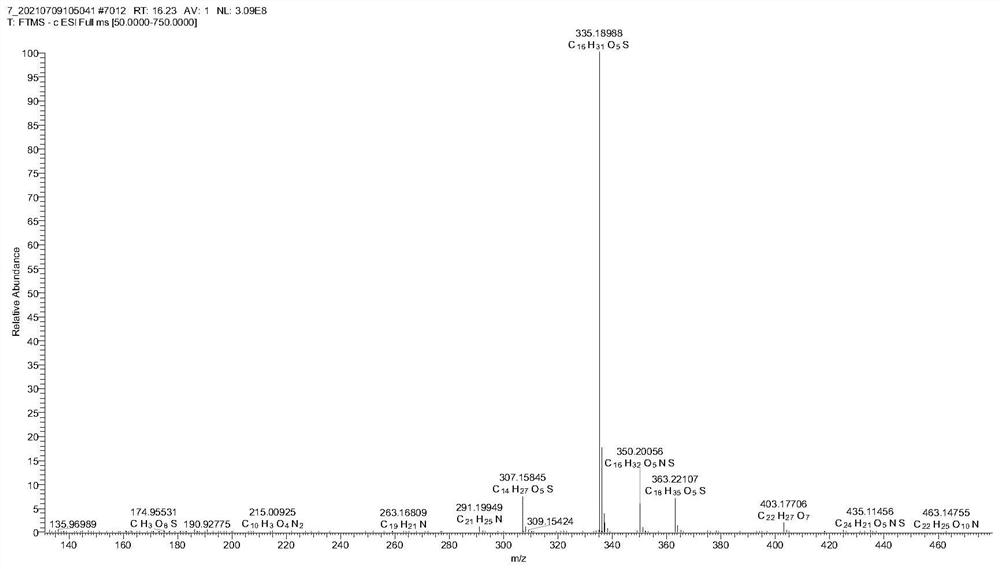

[0063] The present embodiment provides a hydroxamic acid sulfonic acid compound: 1-(hydroxyamino)-1-oxohexadecane-2-sulfonic acid, the preparation process of which is as follows:

[0064] Mix 20.0 g of potassium 1-methoxy-1-oxohexadecane-2-sulfonate and 4 mL of 50% hydroxylamine, then add 7.0 g of KOH catalyst, heat to 50 ° C, react for 6 hours, and finally add concentrated sulfuric acid to adjust the pH to 7. Suction filtration and use distilled water to remove inorganic salts and raw material sulfonates to obtain 14.3 g of a mixture of 1-(hydroxyamino)-1-oxohexadecane-2-sulfonic acid, and use Kjeldahl method to demarcate N in the mixture content, the yield was 57.8%.

Embodiment 3

[0066] The present embodiment provides a hydroxamic acid sulfonic acid compound: 1-(hydroxyamino)-1-oxotetradecane-2-sulfonic acid, the preparation process of which is as follows:

[0067] Mix 20.0 g of sodium 1-methoxy-1-oxotetradecane-2-sulfonate and 5 mL of 40% hydroxylamine, then add 6.5 g of NaOH catalyst, heat to 55°C, react for 6 hours, and finally add concentrated sulfuric acid to adjust pH to 7. Suction filtration, and use distilled water to remove inorganic salts and raw material sulfonates to obtain 22.9 g of a mixture of 1-(hydroxyamino)-1-oxotetradecane-2-sulfonic acid and use Kjeldahl method to calibrate N in the mixture content, the yield was 72.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com