Alkali-free fluorine-free chlorine-free liquid concrete accelerator and preparation method thereof

A technology of quick-setting agent and concrete, applied in the field of environment-friendly concrete quick-setting agent, can solve problems such as performance and adverse effects on human health, and achieve the effects of shortening the initial and final setting time, promoting cement hydration, and improving the quick-setting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

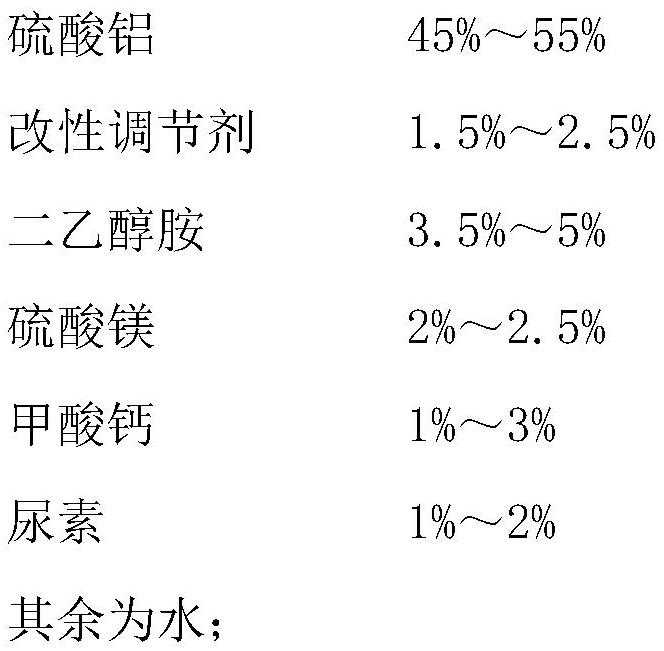

[0021] The mass percent of each component of a liquid alkali-free, fluorine-free and chlorine-free concrete quick-setting agent is: 45% of aluminum sulfate, 1.5% of modified regulator, 3.5% of diethanolamine, 2% of magnesium sulfate, 1% of calcium formate, 1% of urea %, the rest is water, and the sum of each component is 100%.

[0022] The preparation method is:

[0023] Weigh according to the proportion of raw materials, first add water to the reaction kettle, stir while heating and gradually add aluminum sulfate; after the temperature is controlled at 55°C, add magnesium sulfate and calcium formate in sequence every 5 minutes, and continue to stir for 1.5 h; after natural cooling to room temperature, add urea, modified regulator and diethanolamine, and then stir for 20 minutes to control the pH of the quick-setting agent solution to 2.5 to obtain the finished liquid concrete quick-setting agent. The performance test results are shown in Table 1.

[0024] Among them, the pre...

Embodiment 2

[0026] The mass percent of each component of a liquid alkali-free, fluorine-free and chlorine-free concrete quick-setting agent is: 50.5% of aluminum sulfate, 1.8% of modified regulator, 4% of diethanolamine, 2.2% of magnesium sulfate, 2.5% of calcium formate, and 1.5% of urea %, the rest is water, and the sum of each component is 100%.

[0027] The preparation method is:

[0028] Weigh according to the ratio of raw materials, first add water to the reaction kettle, stir while heating and gradually add aluminum sulfate; after the temperature is controlled at 60°C, add magnesium sulfate and calcium formate in sequence every 7 minutes, and continue stirring for 1.8 hours After natural cooling to normal temperature, add urea, modified modifier and diethanolamine, and then stir for 25 minutes to control the pH of the quick-setting agent solution to 2.7 to obtain the finished liquid concrete quick-setting agent. The performance test results are shown in Table 1.

[0029] Among the...

Embodiment 3

[0031] The mass percent of each component of a liquid alkali-free, fluorine-free and chlorine-free concrete quick-setting agent is: 55% of aluminum sulfate, 2.5% of modified regulator, 5% of diethanolamine, 2.5% of magnesium sulfate, 3% of calcium formate, 2% of urea %, the rest is water, and the sum of each component is 100%.

[0032] The preparation method is:

[0033] Weigh according to the proportion of raw materials, first add water to the reaction kettle, stir while heating and gradually add aluminum sulfate; after the temperature is controlled at 65°C, add magnesium sulfate and calcium formate in sequence every 8 minutes, and continue stirring for 2 hours; After natural cooling to room temperature, add urea, modified regulator and diethanolamine, and then stir for 30 minutes to control the pH of the quick-setting agent solution to 3 to obtain the finished liquid concrete quick-setting agent. The performance test results are shown in Table 1.

[0034] Among them, the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com