Laser-electric arc hybrid welding process for steel for medium-thickness plate ocean platform

A hybrid welding and offshore platform technology, applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve problems such as hindering arc welding droplet transfer, increasing laser reflectivity, reducing energy utilization, etc. The effect of refinement, promotion of droplet transfer, and arc energy concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

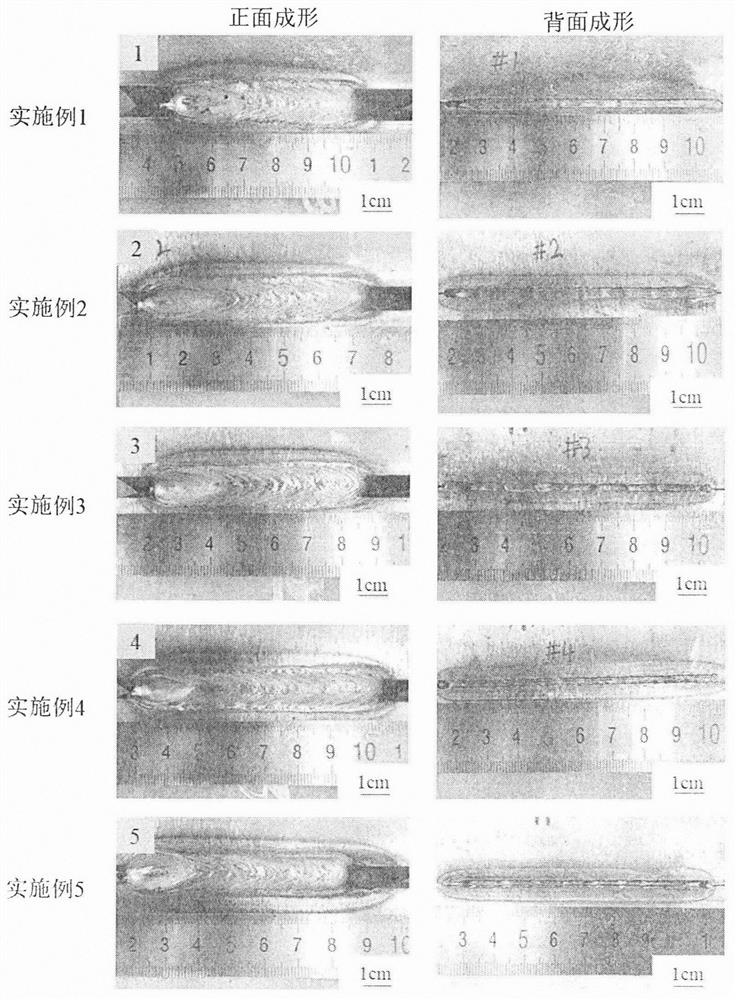

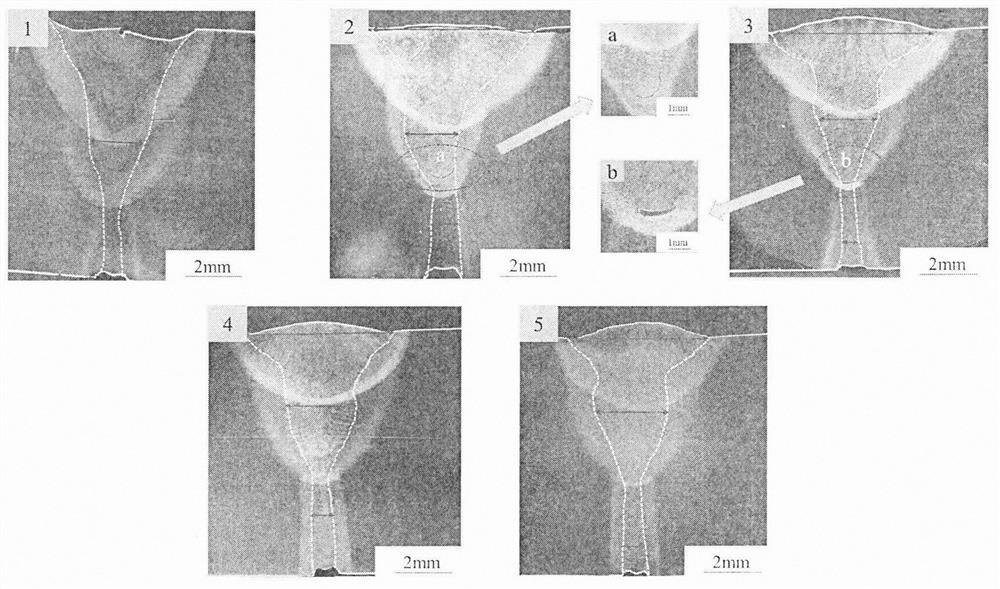

Embodiment 1

[0019] Using 20mm EH36 steel thick plate as the welding base material, the sample size is processed to 100mm×50mm by wire cutting, the groove is Y-shaped groove angle is 30°, the blunt edge is 6mm, and no gap is left. The joint form is plane butt joint; alcohol is used for cleaning before welding.

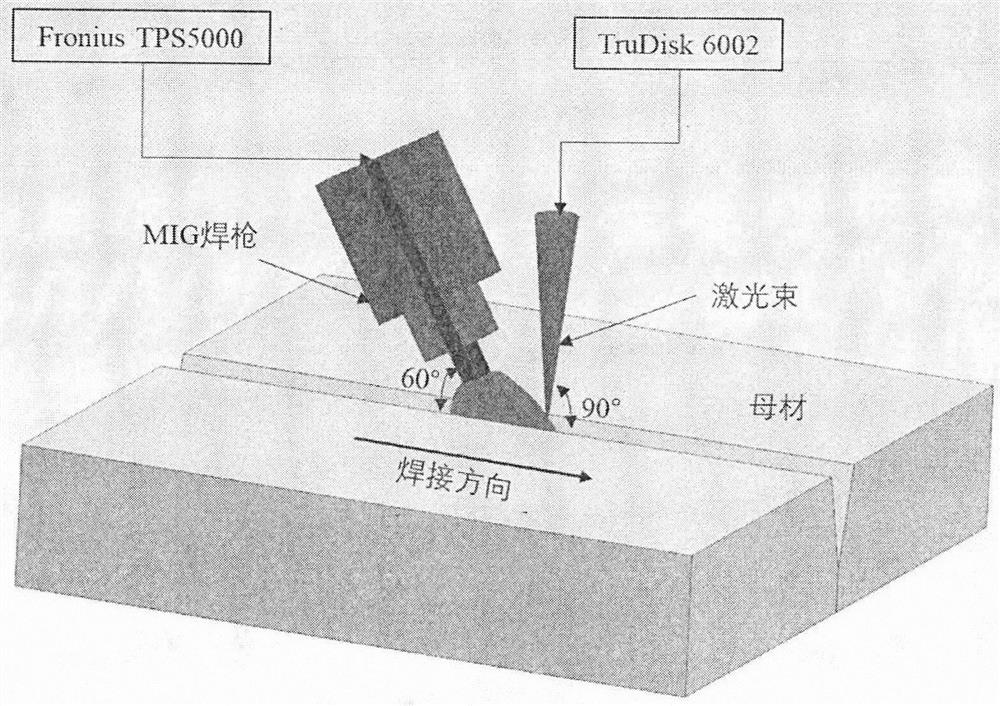

[0020] The first layer of root welding uses laser alone as the welding heat source, and the equipment uses TruDisk 6002 laser. The angle between the laser and the plate is 90°, the defocus is ±3mm, the laser power is 4kW, the welding speed is 0.01m / s, the shielding gas is argon, the flow rate of the shielding gas on the surface is 35L / min, and the flow rate on the back is 20L / min; The second and third layers of filling welding adopt laser arc composite heat source, the angle between the laser and the plate is 90°, the arc equipment adopts Fronius TPS5000 welding machine, the angle between the arc and the plate is 60°, and the distance between the arc and the laser arc is 5-6mm. Th...

Embodiment 2

[0023] Using 20mm EH36 steel thick plate as the welding base material, the sample size is processed to 100mm×50mm by wire cutting, the groove is Y-shaped groove angle is 30°, the blunt edge is 6mm, and no gap is left. The joint form is plane butt joint; use alcohol to clean the workpiece before welding.

[0024] The first layer of root welding uses laser alone as the welding heat source, and the equipment uses TruDisk 6002 laser. The angle between the laser and the plate is 90°, the defocus is ±3mm, the laser power is 4kW, the welding speed is 0.01m / s, the shielding gas is argon, the flow rate of the shielding gas on the surface is 35L / min, and the flow rate on the back is 20L / min; The second and third layers of filling welding adopt laser arc composite heat source, the angle between the laser and the plate is 90°, the arc equipment adopts Fronius TPS5000 welding machine, the angle between the arc and the plate is 60°, and the distance between the arc and the laser arc is 5-6m...

Embodiment 3

[0027] Using 20mm EH36 steel thick plate as the welding base material, the sample size is processed to 100mm×50mm by wire cutting, the groove is Y-shaped groove angle is 30°, the blunt edge is 6mm, and no gap is left. The joint form is plane butt joint; use alcohol to clean the workpiece before welding.

[0028] The first layer of root welding uses laser alone as the welding heat source, and the equipment uses TruDisk 6002 laser. The angle between the laser and the plate is 90°, the defocus is ±3mm, the laser power is 4kW, the welding speed is 0.01m / s, the shielding gas is argon, the flow rate of the shielding gas on the surface is 35L / min, and the flow rate on the back is 20L / min; The second and third layers of filling welding adopt laser arc composite heat source, the angle between the laser and the plate is 90°, the arc equipment adopts Fronius TPS5000 welding machine, the angle between the arc and the plate is 60°, and the distance between the arc and the laser arc is 5-6m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com