Water-soluble sarafloxacin hydrochloride granule and preparation method thereof

A technology of sarafloxacin hydrochloride and water-soluble granules, which is applied in the field of sarafloxacin hydrochloride water-soluble granules and its preparation, can solve the problems of ineffective treatment, drug residue, and prolonged drug withdrawal period, and achieve good treatment effect, does not affect the drug withdrawal period, and the effect of strong drug loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The present embodiment proposes a kind of method of sarafloxacin hydrochloride water-soluble granule, comprises the steps:

[0024] (1) Weigh 15 g of diethylenediamine and 150 g of cyclodextrin-methyl vinyl ether / maleic anhydride copolymer respectively, add them into hot water at 55°C, stir and mix evenly, and obtain mixture 1;

[0025] (2) Weigh 100 g of sarafloxacin hydrochloride and 735 g of anhydrous glucose respectively, and stir and mix evenly to obtain mixture 2;

[0026] (3) Throw the mixture 2 obtained in the step (2) into a three-dimensional fluidized bed, and use the mixture 1 obtained in the step (1) as a binder for fluidized bed granulation; during this period, control the inlet air temperature, Inlet air volume, atomization pressure, and finally obtain sarafloxacin hydrochloride granules.

Embodiment 2

[0028] The present embodiment proposes a kind of method of sarafloxacin hydrochloride water-soluble granule, comprises the steps:

[0029] (1) Weigh 30g of diethylenediamine and 200g of cyclodextrin-methyl vinyl ether / maleic anhydride copolymer respectively, add them into hot water at 58°C and stir and mix evenly to obtain mixture 1;

[0030] (2) Weigh 100 g of sarafloxacin hydrochloride and 670 g of anhydrous glucose respectively, and stir and mix evenly to obtain mixture 2;

[0031] (3) Throw the mixture 2 obtained in the step (2) into a three-dimensional fluidized bed, and use the mixture 1 obtained in the step (1) as a binder for fluidized bed granulation; during this period, control the inlet air temperature, Inlet air volume, atomization pressure, and finally obtain sarafloxacin hydrochloride granules.

Embodiment 3

[0033] The present embodiment proposes a kind of method of sarafloxacin hydrochloride water-soluble granule, comprises the steps:

[0034] (1) Weigh 45g of diethylenediamine and 220g of cyclodextrin-methyl vinyl ether / maleic anhydride copolymer respectively, add them into hot water at 60°C, stir and mix evenly, and obtain mixture 1;

[0035] (2) Weigh 100 g of sarafloxacin hydrochloride and 635 g of anhydrous glucose respectively, and stir and mix evenly to obtain mixture 2;

[0036] (3) Throw the mixture 2 obtained in the step (2) into a three-dimensional fluidized bed, and use the mixture 1 obtained in the step (1) as a binder for fluidized bed granulation; during this period, control the inlet air temperature, Inlet air volume, atomization pressure, and finally obtain sarafloxacin hydrochloride granules.

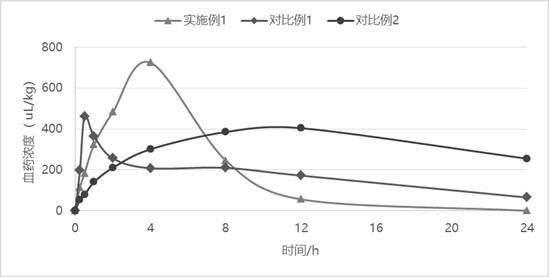

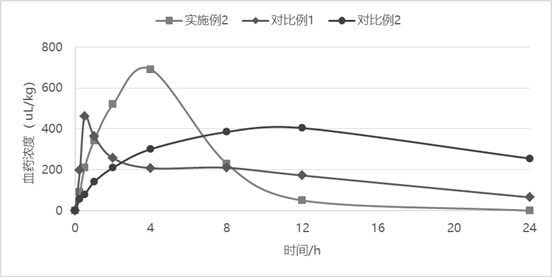

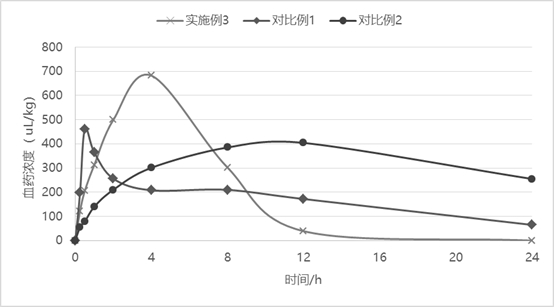

[0037] For the above-mentioned Examples 1 to 3, in order to facilitate comparative analysis, the stirring speed in step (1) was 150 r / min, and the stirring time was 30 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com