Manufacturing method of concave metal mesh of fairing

A technology of metal mesh grid and manufacturing method, which is applied to electrical components, magnetic field/electric field shielding and other directions, can solve the problems of complex process of concave metal mesh of fairing, difficult to guarantee spherical surface uniformity, difficult to control process parameters, etc., so as to avoid product damage. , the effect of saving production costs and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

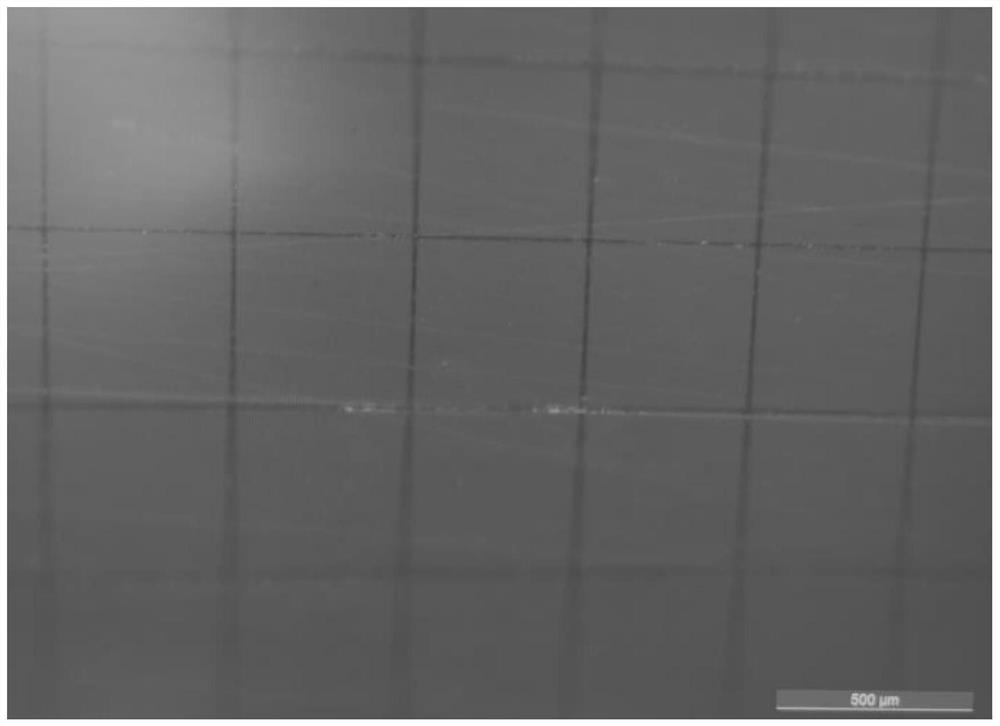

Image

Examples

Embodiment 1

[0030] Making the concave metal mesh grid of the fairing with a curvature R=116mm and a sagittal height of 80.5mm includes the following steps:

[0031] 1) Soak the degreased cotton with a mixture of alcohol and ether with a mass ratio of 3:7 to scrub the fairing to remove surface impurities, oil stains and auxiliary materials;

[0032] 2) Fix the fairing after cleaning in step 1) on the rotary coating machine, with the concave side facing upwards, drop the positive photoresist on the concave surface of the fairing with a dropper, first rotate the fairing manually to make the positive photoresist evenly Fill the entire concave surface of the fairing, and then start the rotary coating machine for automatic spin coating, the speed is 1000r / s, and the time is 2min;

[0033] 3) Put the fairing coated with photoresist on the concave surface of step 2) into a baking oven and take it out after baking at 80°C for 30 minutes;

[0034] 4) Install the fairing after baking in step 3) on ...

Embodiment 2

[0039] Making the concave metal grid of the fairing with a curvature R=132mm and a sagittal height of 106mm includes the following steps:

[0040] 1) Soak the degreased cotton with a mixture of alcohol and ether with a mass ratio of 4:6 and scrub the fairing to remove surface impurities, oil stains and auxiliary materials;

[0041] 2) Fix the fairing after cleaning in step 1) on the rotary coating machine, with the concave side facing upwards, drop the positive photoresist on the concave surface of the fairing with a dropper, first rotate the fairing manually to make the positive photoresist evenly Fill the entire concave surface of the fairing, and then start the rotary coating machine for automatic spin coating, the speed is 1200r / s, and the time is 1min;

[0042] 3) Put the fairing coated with photoresist on the concave surface of step 2) into a baking oven and take it out after baking at 80°C for 25 minutes;

[0043] 4) Install the fairing after baking in step 3) on the c...

Embodiment 3

[0048] Making the concave metal mesh grid of the fairing with a curvature R=125mm and a sagittal height of 95.5mm includes the following steps:

[0049] 1) Soak the degreased cotton with a mixture of alcohol and ether with a mass ratio of 3:6 and scrub the fairing to remove surface impurities, oil stains and auxiliary materials;

[0050] 2) Fix the fairing after cleaning in step 1) on the rotary coating machine, with the concave side facing upwards, drop the positive photoresist on the concave surface of the fairing with a dropper, first rotate the fairing manually to make the positive photoresist evenly Fill the entire fairing concave surface, and then start the rotary coating machine for automatic spin coating, the speed is 1500r / s, and the time is 1.5min;

[0051] 3) Put the fairing coated with photoresist on the concave surface of step 2) into a baking oven and take it out after baking at 100°C for 20 minutes;

[0052] 4) Install the fairing after baking in step 3) on the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com