Phosphorus-doped nickel aluminum oxide and preparation method and application thereof

A nickel-aluminum oxide and phosphorus doping technology, which is applied in chemical instruments and methods, preparation of liquid hydrocarbon mixtures, metal/metal oxide/metal hydroxide catalysts, etc., can solve phase transition, deactivation, and carbon deposition and other problems, to achieve the effect of cheap and easy-to-obtain raw materials, high stability, and inhibition of metal agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

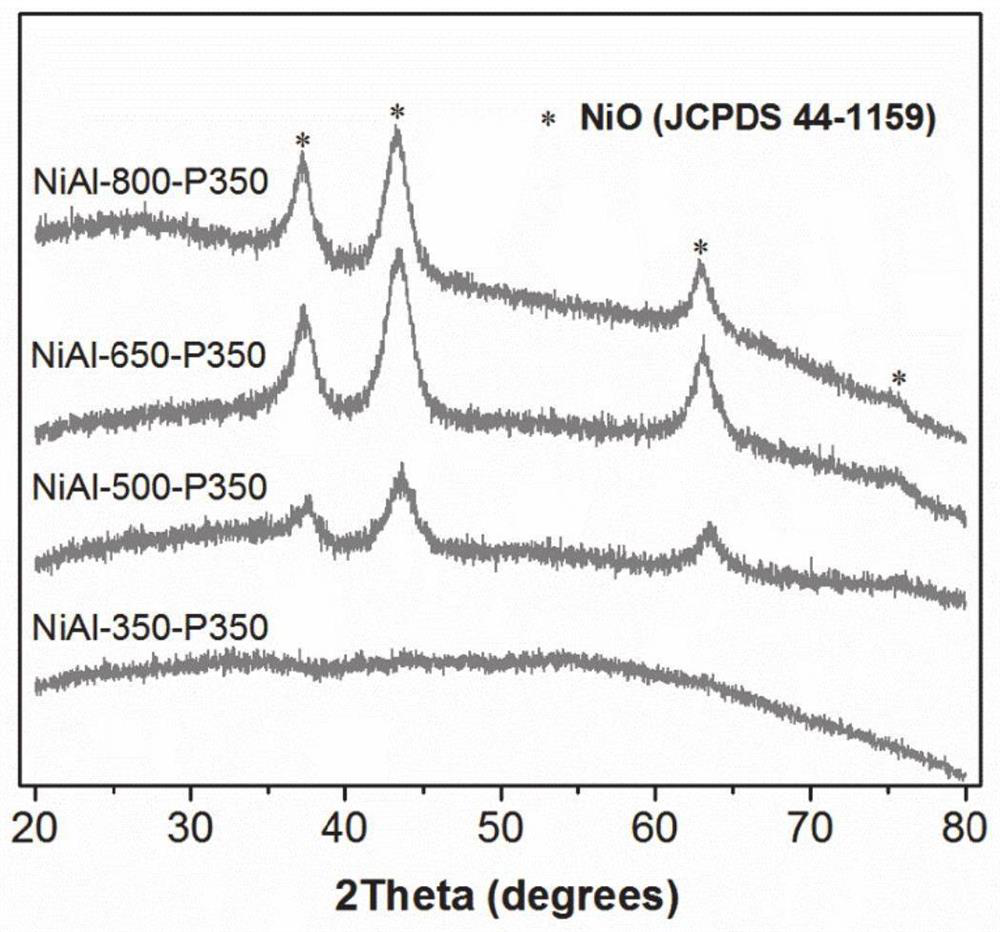

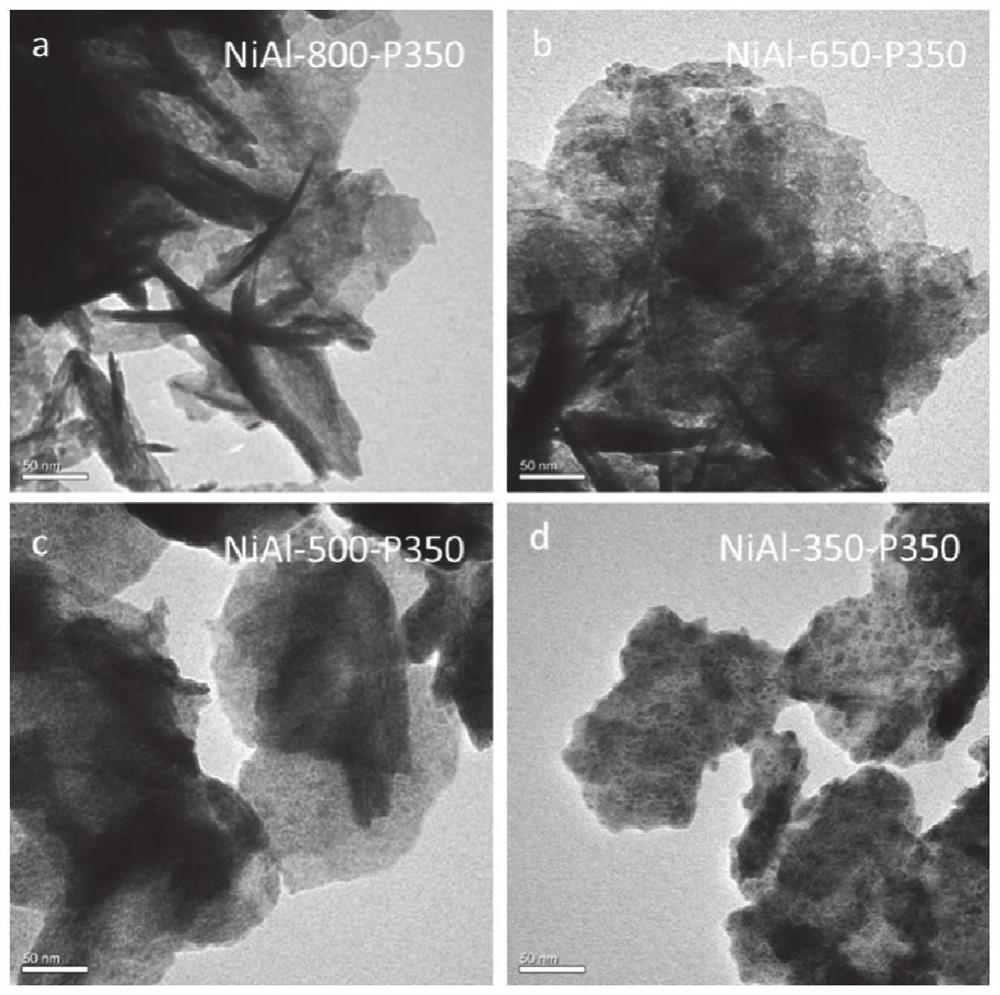

[0055] Preparation of phosphorus doped nickel aluminum oxide (NiAl-800-P350):

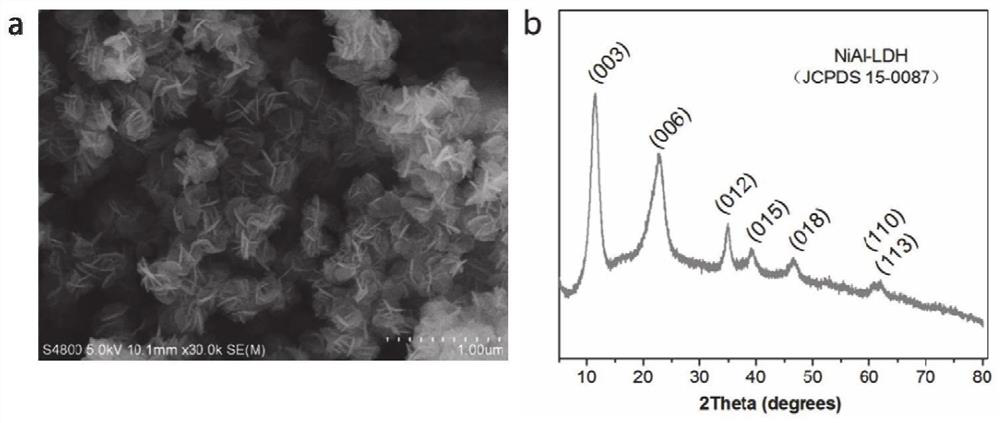

[0056] a) Add 9mmol Ni(NO 3 ) 2 ·6H 2 O, 3mmol Al(NO 3 ) 3 9H 2 O. Dissolve 27mmol of urea in 90mL of deionized water, stir until clarified, put it into a polytetrafluoroethylene hydrothermal kettle, and place it in an oven at 100°C for 24h;

[0057] b) After the hydrothermal reaction is completed, a hydrotalcite-like precipitate is obtained, and the precipitate is separated by suction filtration, washed with water for 3-5 times, and dried in an oven at 80° C. for 12 hours;

[0058] c) Grind the dried sample until it is fine and uniform, then place it in a muffle furnace for aerobic calcination, the heating rate is 10 ℃ / min, the calcination temperature is 800 ℃, keep it for 1 hour, and then drop to room temperature;

[0059] d) Weigh 0.1g of the obtained oxide, 1.0g of sodium hypophosphite (NaH 2 PO 2 ) in a quartz tube, purged with argon (100mL / min) for 30min, then evacuated the reaction s...

Embodiment 2

[0061] Preparation of phosphorus doped nickel aluminum oxide (NiAl-650-P350):

[0062] a) Add 9mmol Ni(NO 3 ) 2 ·6H 2 O, 3mmol Al(NO 3 ) 3 9H 2 O. Dissolve 27mmol of urea in 90mL of deionized water, stir until clarified, put it into a polytetrafluoroethylene hydrothermal kettle, and place it in an oven at 100°C for 24h;

[0063] b) After the hydrothermal reaction is completed, a hydrotalcite-like precipitate is obtained, and the precipitate is separated by suction filtration, washed with water for 3-5 times, and dried in an oven at 80° C. for 12 hours;

[0064] c) Grind the dried sample until it is fine and uniform, and then place it in a muffle furnace for aerobic roasting at a heating rate of 10 °C / min at a roasting temperature of 650 °C, keep it for 1 hour, and then cool down to room temperature;

[0065] d) Weigh 0.1g of the obtained oxide, 1.0g of sodium hypophosphite (NaH 2 PO 2 ) in a quartz tube, purged with argon (100mL / min) for 30min, then evacuated the react...

Embodiment 3

[0067] Preparation of phosphorus doped nickel aluminum oxide (NiAl-500-P350):

[0068] a) Add 9mmol Ni(NO 3 ) 2 ·6H 2 O, 3mmol Al(NO 3 ) 3 9H 2 O. Dissolve 27mmol of urea in 90mL of deionized water, stir until clarified, put it into a polytetrafluoroethylene hydrothermal kettle, and place it in an oven at 100°C for 24h;

[0069] b) After the hydrothermal reaction is completed, a hydrotalcite-like precipitate is obtained, and the precipitate is separated by suction filtration, washed with water for 3-5 times, and dried in an oven at 80° C. for 12 hours;

[0070] c) Grind the dried sample until it is fine and uniform, then place it in a muffle furnace for aerobic calcination, the heating rate is 10 ℃ / min, the calcination temperature is 500 ℃, keep it for 1 hour, and then cool down to room temperature;

[0071] d) Weigh 0.1g of the obtained oxide, 1.0g of sodium hypophosphite (NaH 2 PO 2 ) in a quartz tube, purged with argon (100mL / min) for 30min, then evacuated the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com